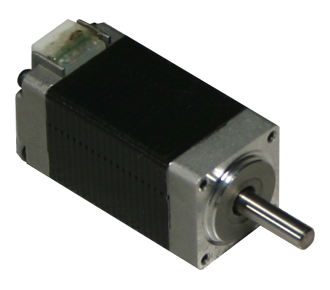

Featured High Torque (Square) Stepper Motors

- Frame Size: NEMA 08

- Holding Torque: 2.5-4.9 oz-in.

- Current: 0.6-1.1A

- Frame Size: NEMA 11

- Holding Torque: 8.3-16.7 oz-in.

- Current: 0.2-0.7A

- Frame Size: NEMA 14

- Holding Torque: 9-59 oz-in.

- Current: 0.3-1.5A

- Frame Size: NEMA 15

- Holding Torque: 9-50 oz-in.

- Current: 0.4-1.6A

- Frame Size: NEMA 17

- Holding Torque: 24-111 oz-in.

- Current: 0.4-3.0A

- Frame Size: NEMA 17

- Holding Torque: 31-86 oz-in.

- Current: 0.2-1.2A

- Frame Size: NEMA 17

- Holding Torque: 38-77 oz-in.

- Current: 0.7-1.1A

- Frame Size: NEMA 23

- Holding Torque: 76-320 oz-in.

- Current: 0.7-3.5A

- Frame Size: NEMA 23

- Holding Torque: 180-270 oz-in.

- Current: 2.12A

- Frame Size: NEMA 23

- Holding Torque: 78-320 oz-in.

- Current: 0.7-3.5A

- Frame Size: NEMA 24

- Holding Torque: 153-431 oz-in.

- Current: 1.4-2.8A

- Frame Size: NEMA 34

- Holding Torque: 467-1700 oz-in.

- Current: 1.4-5.0A

- Frame Size: NEMA 34

- Holding Torque: 635-2140 oz-in.

- Current: 1.4-5.6A

- Compatible with Pacific Scientific N34 Series

- Frame Size: NEMA 34

- Holding Torque: 805-2725 oz-in.

- Current: 1.4-5.6A

- 25% More Torque than 34Y, 34N Series

- Compatible with Pacific Scientific K34 Series

- Frame Size: NEMA 34

- Holding Torque: 467-1700 oz-in.

- Current: 1.4-5.0A

- Frame Size: NEMA 42

- Holding Torque: 1625-4036 oz-in.

- Current: 4.25A

- Frame Size: NEMA 42

- Holding Torque: 1625-4365 oz-in.

- Current: 4.4-7.7A

- Compatible with Pacific Scientific N42 Series

- Frame Size: NEMA 42

- Holding Torque: 2090-5700 oz-in.

- Current: 4.4-7.7A

- 25% More Torque than 42Y,42N Series

- Compatible with Pacific Scientific K42 Series

|

|

.PNG)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)