We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

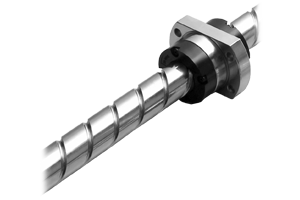

Ball Screws

Ball Screws | Anaheim Automation, Inc.

Information

Anaheim Automation has partnered with TBI Motion to deliver a line of high-accuracy Ball Screws at competitive prices!

These high quality Ball Screw designs offer a substantial savings over other competitive brands, with savings up to 50%. Our Ball Screws are available in both ground and precision-rolled grades from C0 to C10. Offered in screw diameters ranging from 4mm to 80mm with leads from 5mm to 40mm, they can deliver up to 7240 Kgf of dynamic linear force.

Note: For assistance in selecting the appropriate Ball Screw for your application, please complete our Ball Screw Application Sheet and submit it to our Customer Service Representatives.

Ball Screws FAQs

What is a ball screw?

How energy efficient are ball screws?

What is the expected lifetime of a ball screw?

What is the difference between a ball screw and a lead screw?