We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

NEMA, UL, and IP Rating Codes

NEMA, UL, and IP Rating Codes

PDF version: NEMA, UL, and IP Rating Codes.pdf

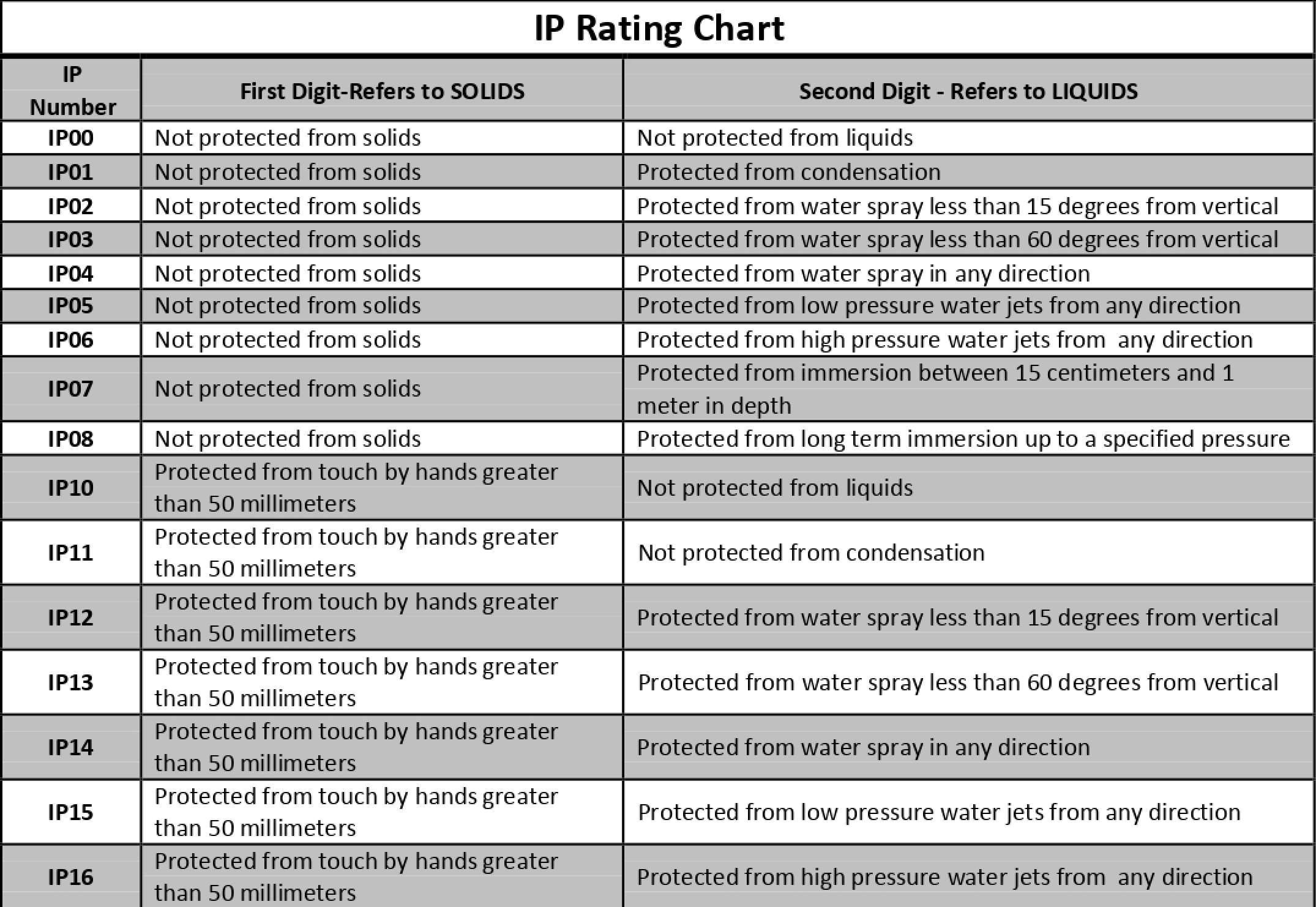

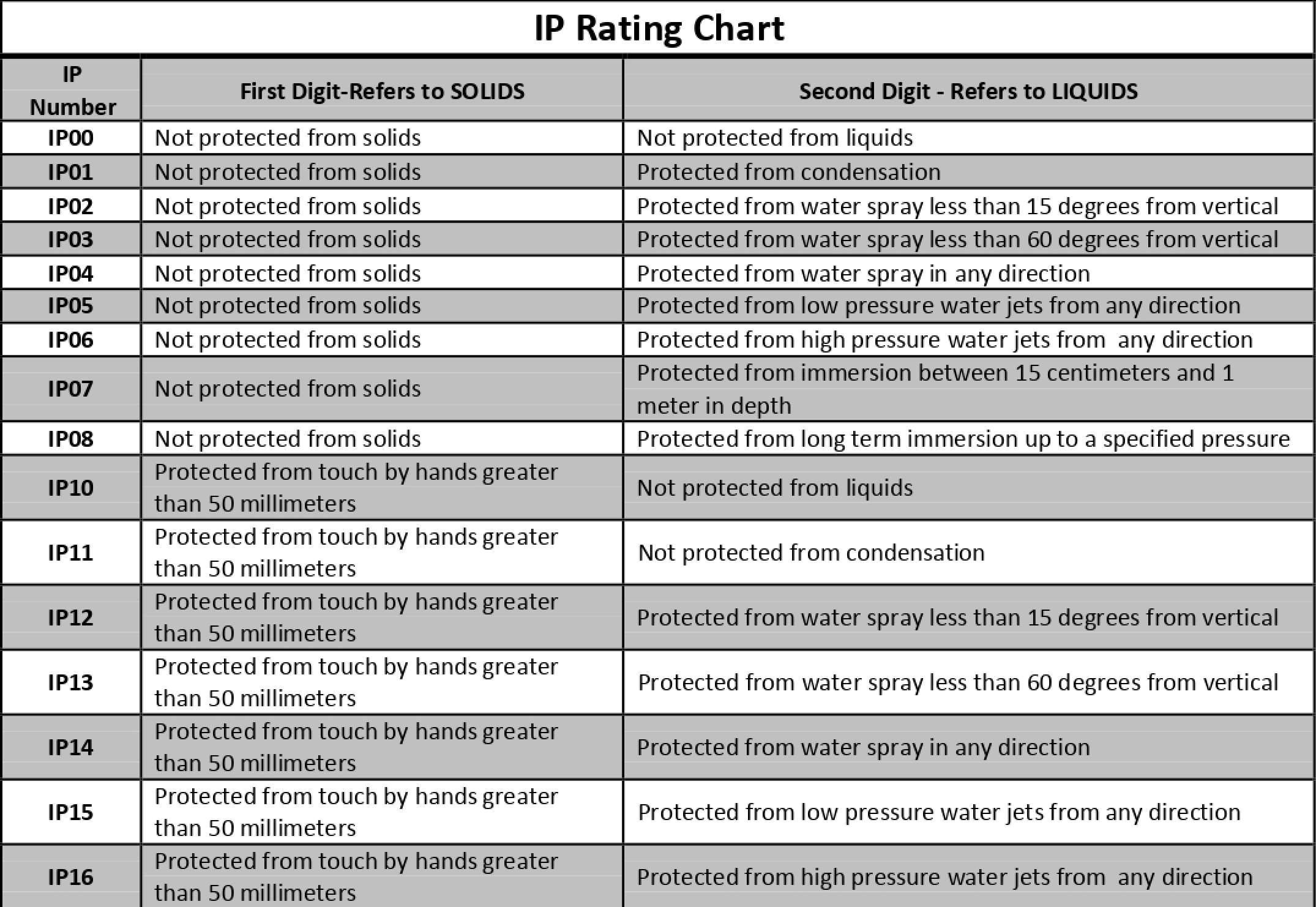

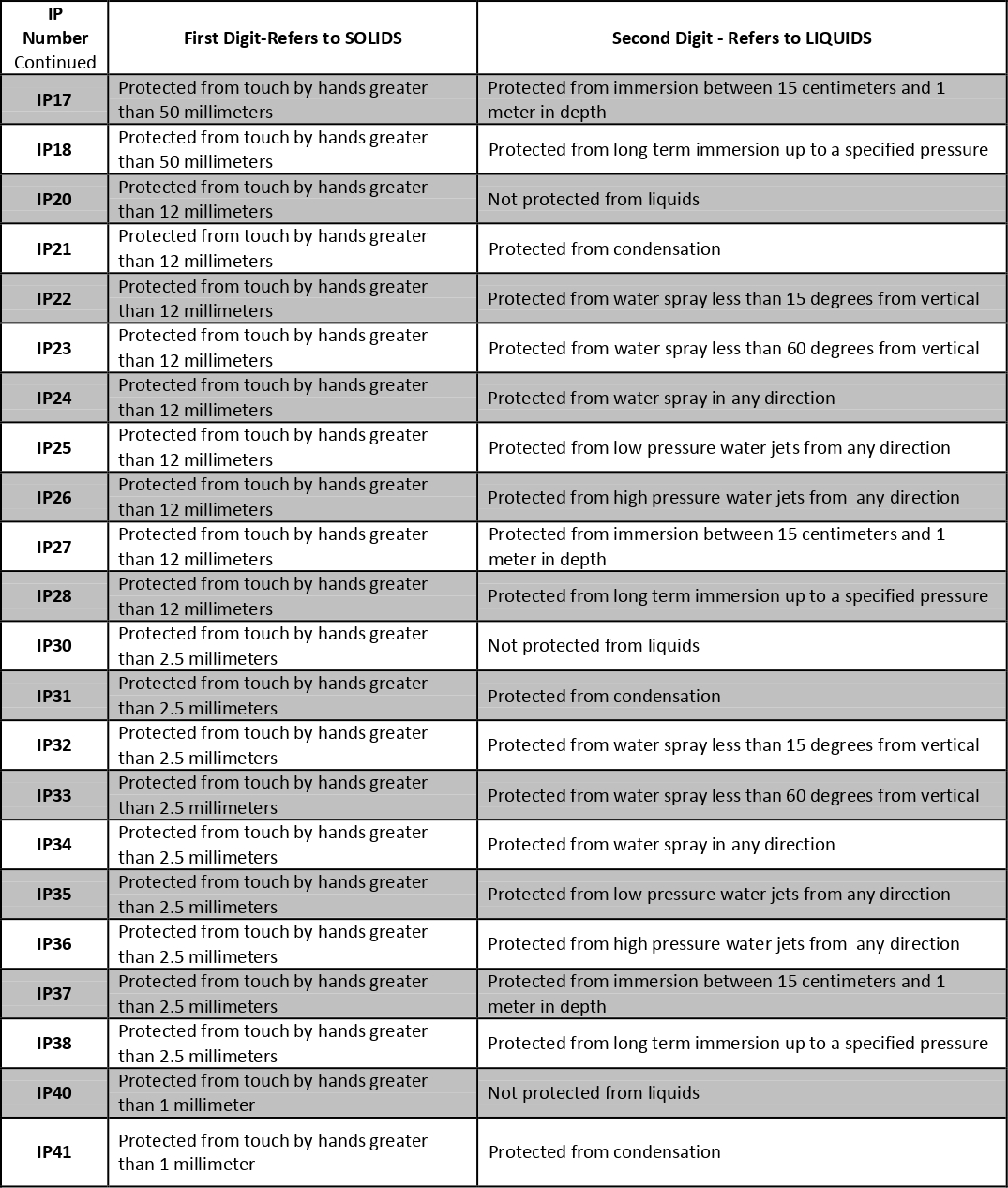

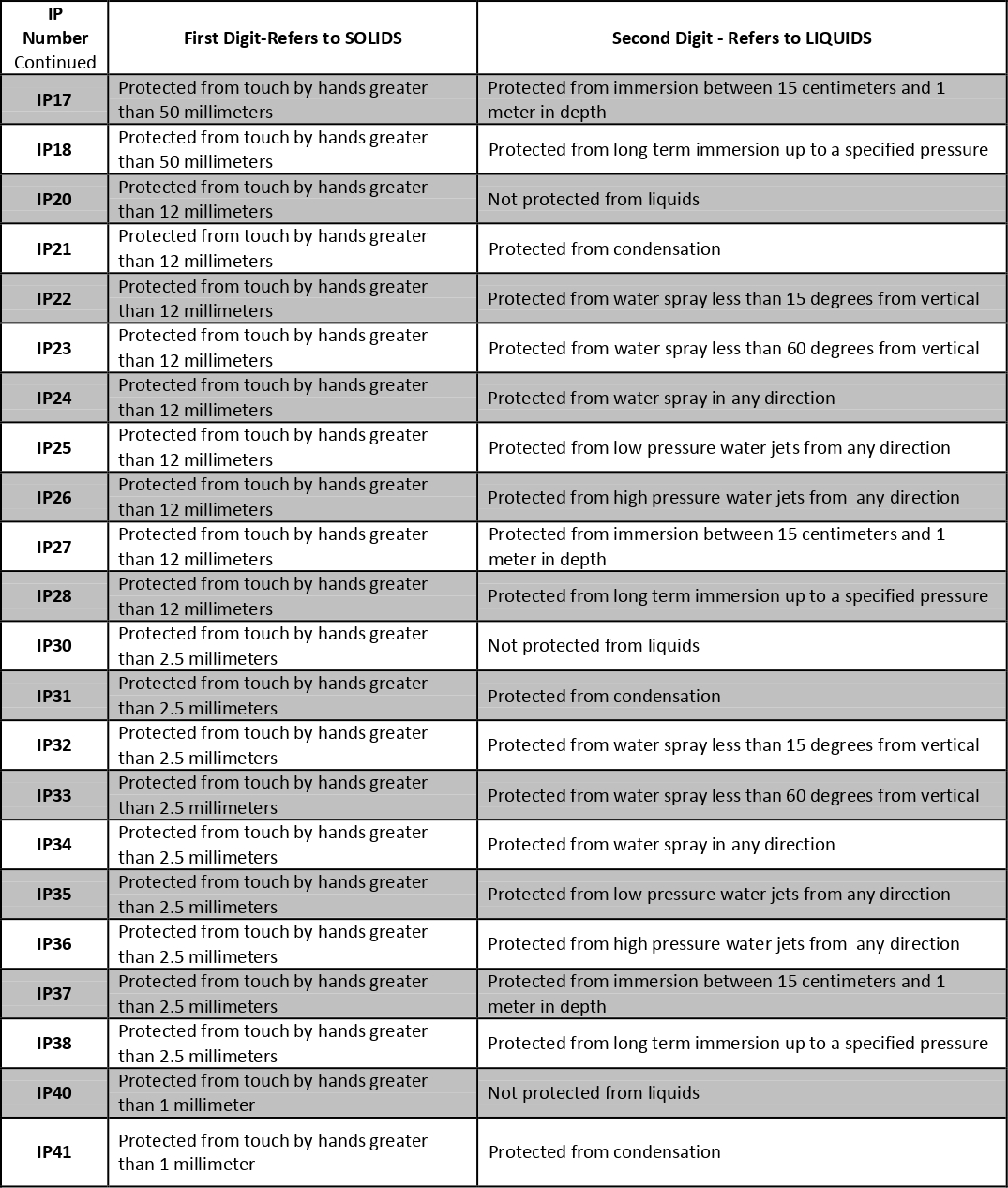

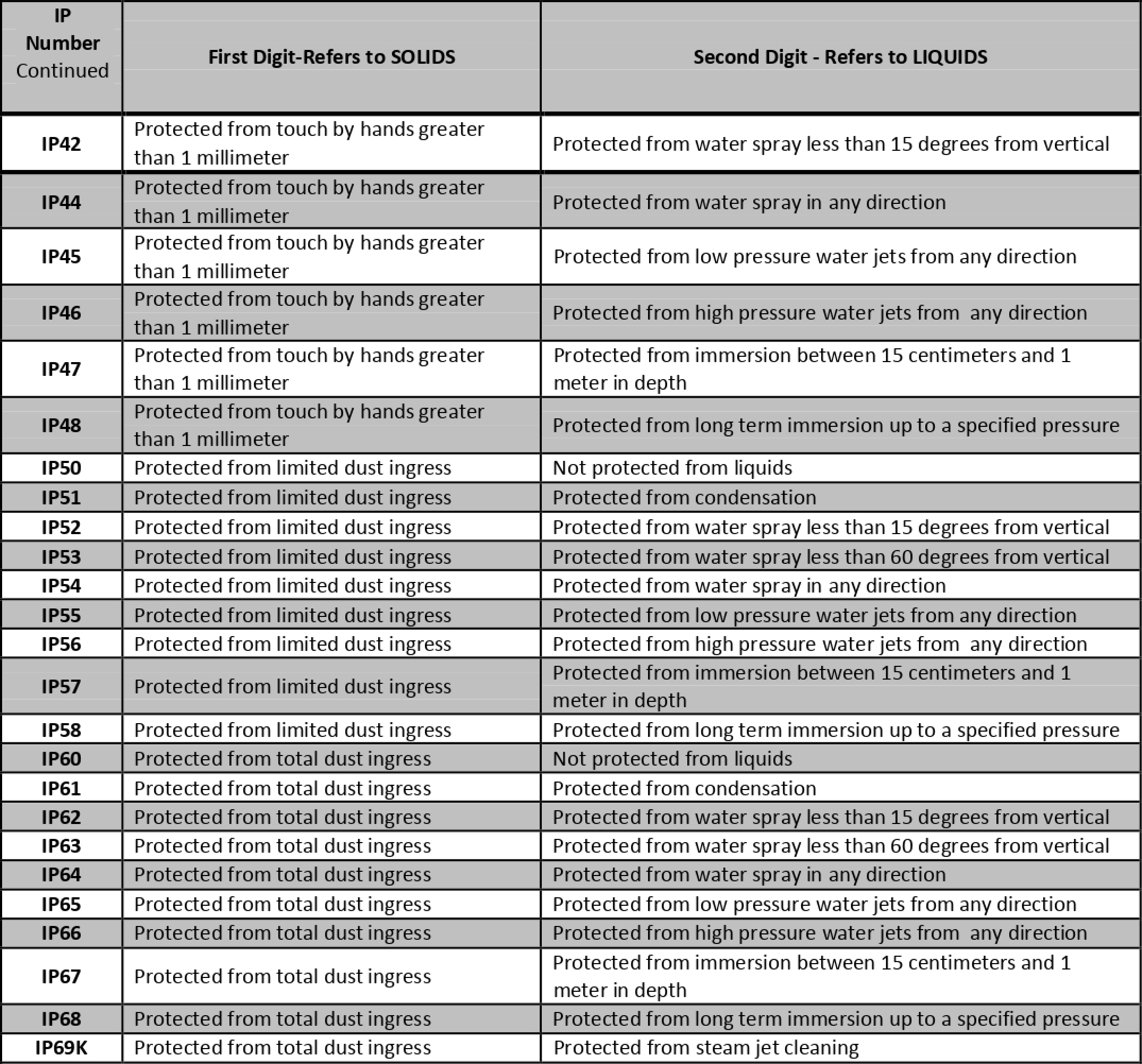

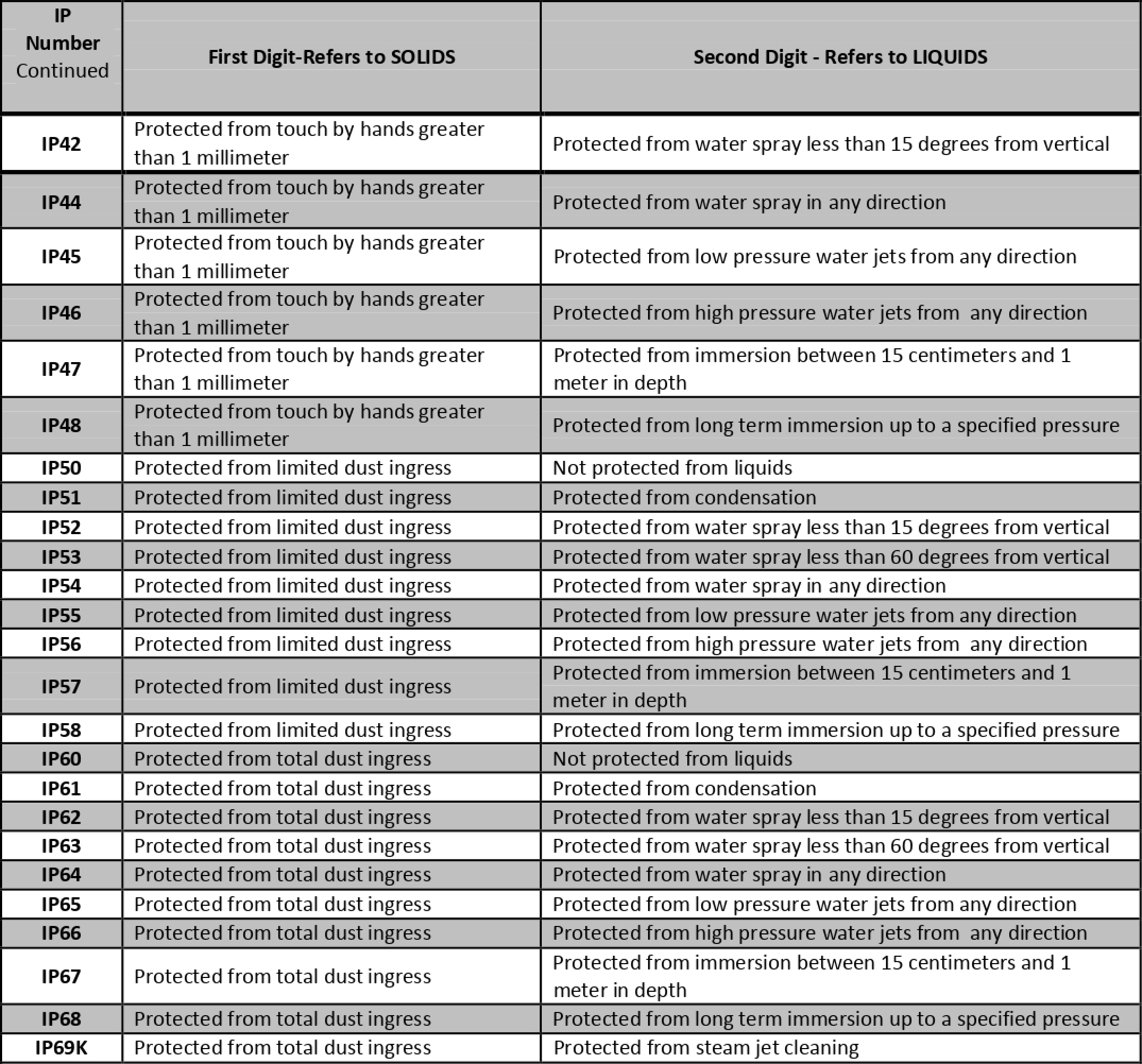

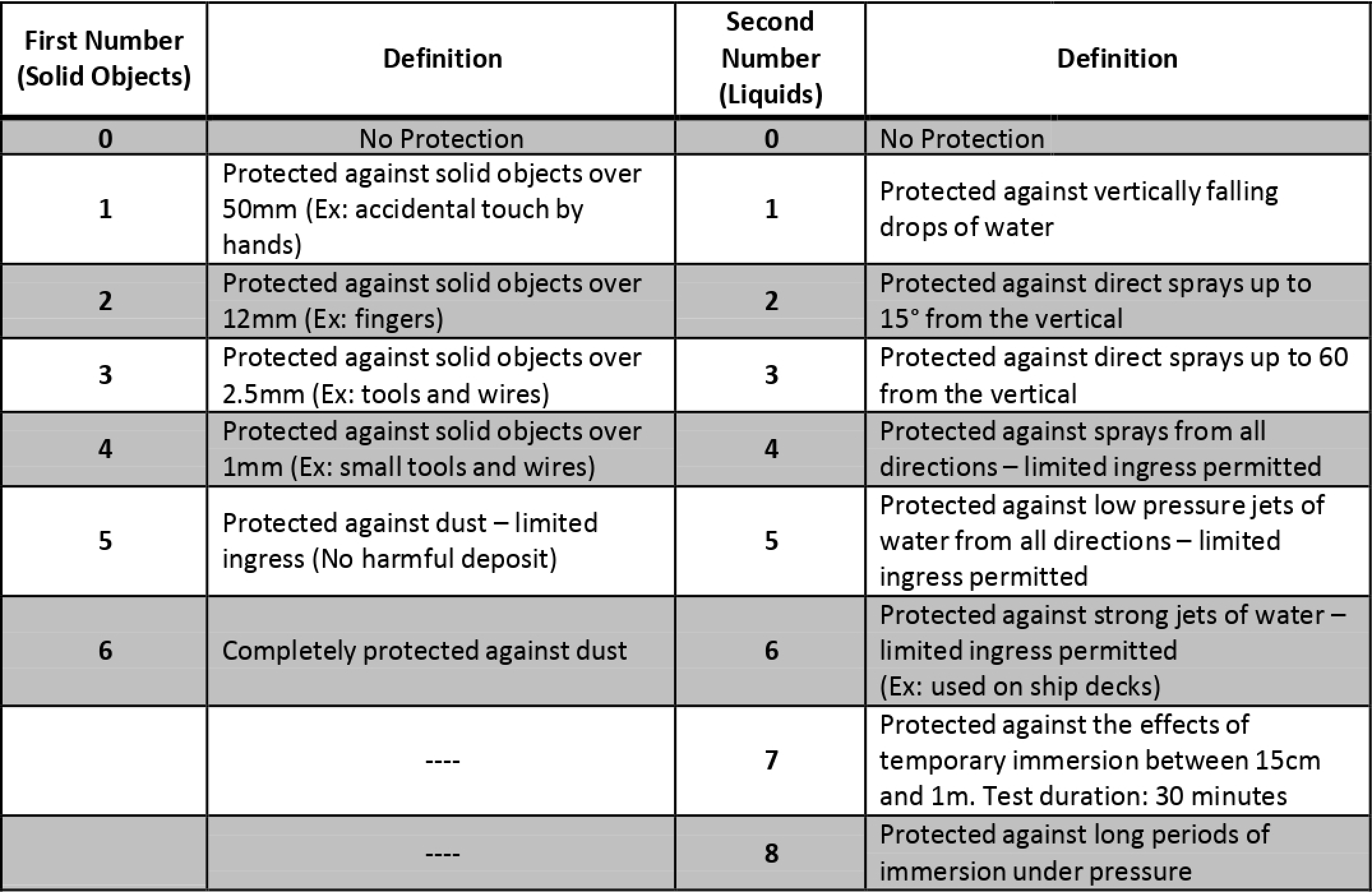

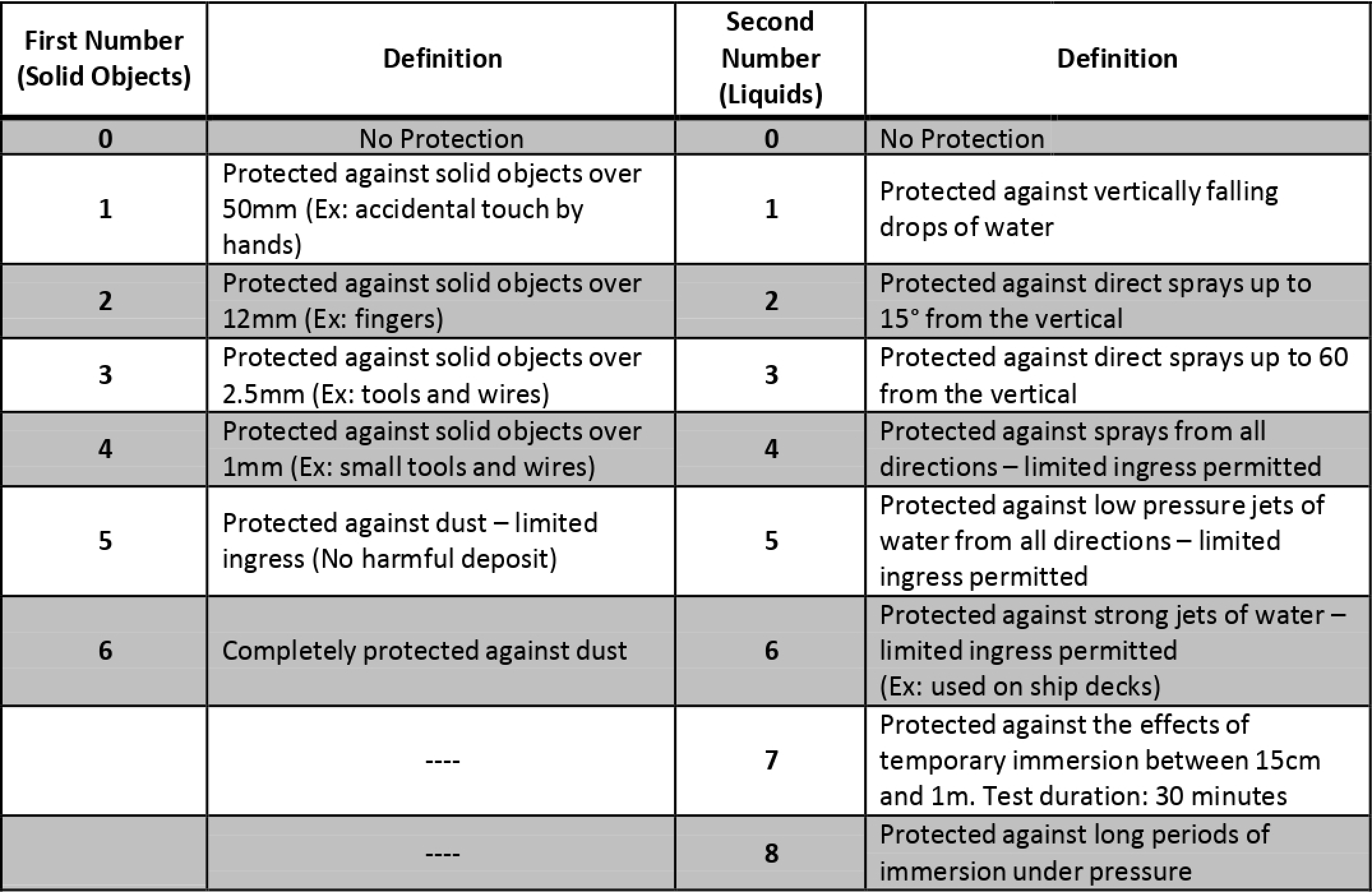

The International Protection Rating,sometimesreferred to as an Ingress Protection rating, is a set of codes used to define specific levels of protection. These codes consist of the prefix IP, followed by two digits (numbers), and an optional letter. IP rating codes are classifications used to measure levels of protection,such as preventing the intrusion of solid objects and liquidsfrom entering an enclosure or motor. Solid objects include body parts such as hands and fingers, as well as dust and debris. Liquids may involve oils, moisture and/or condensation. Typically, IP ratings are used as protection measuresfor motors, electrical devices and control panels. These standards were designed to provide designers with detailed information regarding protection. It is not adequate to state “splash‐proof,” “water‐proof,” or “water‐tight,” as injury to humans and equipment is more likely to occur when vague definitions are used.

The digits noted in the chart below indicate conformity to the conditionstherein. When there is no protection rating with regard to specific criteria, the digit is replaced with the letter “X.” The first digit to follow IP refers to solids, while the next digit refers to liquids. For example, a motor that has an IP65 rating is protected from total dust ingress, as well as protected from low pressure water jets sprayed from any direction.

IP Terms Defined: First Digit – Solids

Level 0 = No protection provided.

Level 1 = >50mm, protects any large surface of the body, such as the back of a hand, but not deliberate contact.

Level 2 = >12.5mm, protects fingers or similarsized objects (pencils or pens).

Level 3 = >2.5mm, protection from possible ingress of tools or thick wires.

Level 4 = >1mm, protection against ingress of most wires and screws.

Level 5 = Dust protection: Ingress of dust is not entirely prevented, but dust cannot interfere with the satisfactory operation of the equipment.

Level 6 = Dust tight; complete protection against ingress of dust.

IP + Second Digit ‐ Liquids

Level 0 = No protection provided.

Level 1 = Dripping water, falling vertically will have no harmful effect. This level meansit must pass a test duration of 10 minutes, with water dripping equivalent to 1mm rainfall per minute.

Level 2 = Dripping water, while tilted up to 15 degrees will have no harmful effects. This level meansit must pass a test duration of 10 minutes, with water dripping equivalent to 3mm rainfall per minute.

Level 3 = Spraying water at an angle of up to 60 degrees from vertical will have no harmful effects. This level means it must pass a test duration of 5 minutes, with a water volume of 0.7 liters per minute, with pressure of 80‐100 KN/m2 .

Level 4 = Water that is splashed against the enclosure from any direction will have no harmful effects. This level means it must pass a test duration of 5 minutes, with a water volume of 10 liters per minute, and a pressure of 80‐100 KN/m2 .

Level 5 = Water jets by a 6.3mm nozzle aimed at an enclosure from any direction will have no harmful effects. This level means it must pass a test duration for a minimum of 3 minutes, with a water volume of 12.5 liters per minute, and a pressure of 80‐100KN/m 2 .

Level 6 = Powerful water jets from a 12.5mm nozzle, aimed at an enclosure from any direction, will have no harmful effects. This level means it must pass a test duration of 3 minutes minimum, with a water volume of 100 liters per minute, with a pressure of 100KN/m2 , at a distance of 3 meters.

Level 7 = Can be immersed in water for 30 minutes, at a depth of 1 meter, and will have no harmful effects.

Level 8 = Continuousimmersion in water under conditionsspecified by the manufacturer. Typically, the equipment is hermetically sealed.

Additional Letters

Additional Letters ‐ Appended to classify the level of protection of humans against access to hazardous parts. (Not always present in the codes, but if stated, the user must use extreme caution with this equipment).

A =Protected against access to hazardous parts with back of hand

B = Protected against hazardous parts with fingers

C = Protected against toolsinterfering with hazardous parts

D = Protection against wire from entering hazardous parts

Further letters can be appended to provide additional information related to the protection of the device and humans:

H = High‐voltage device

M = Device moving during water test

S = Device remaining still during water test

W = Weather conditions

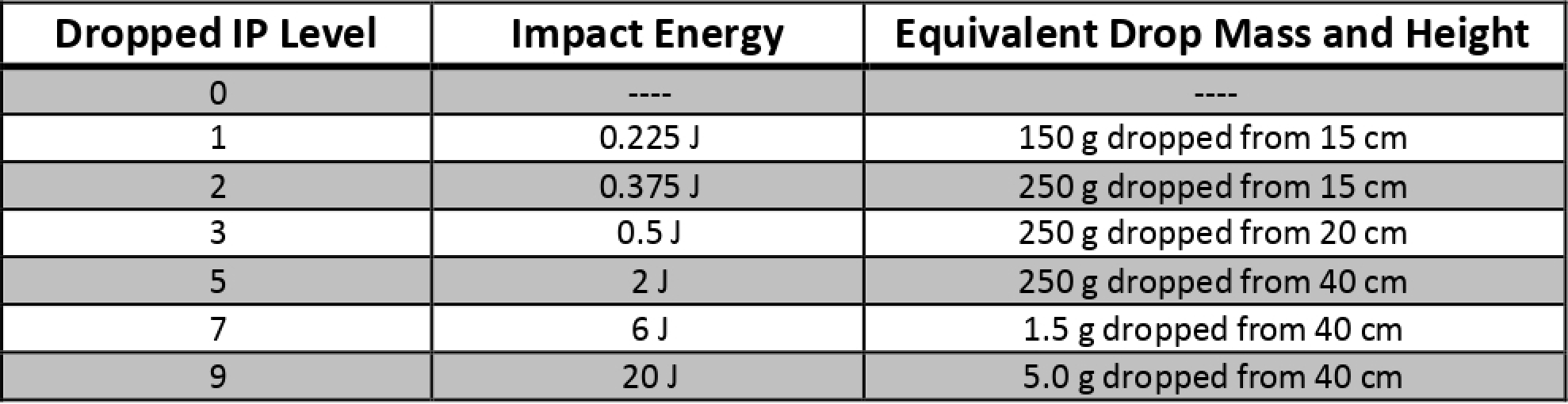

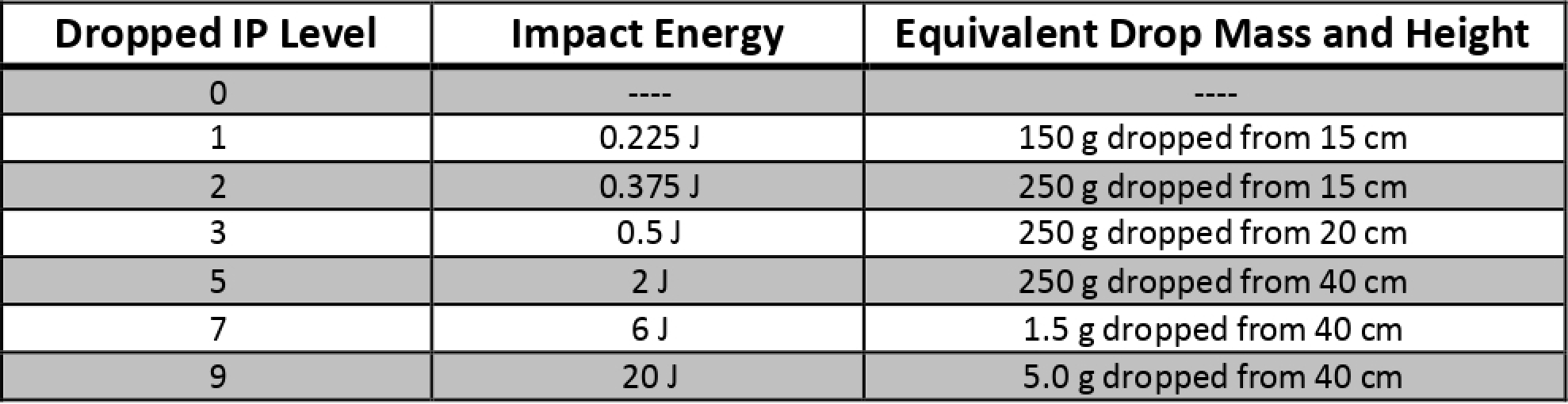

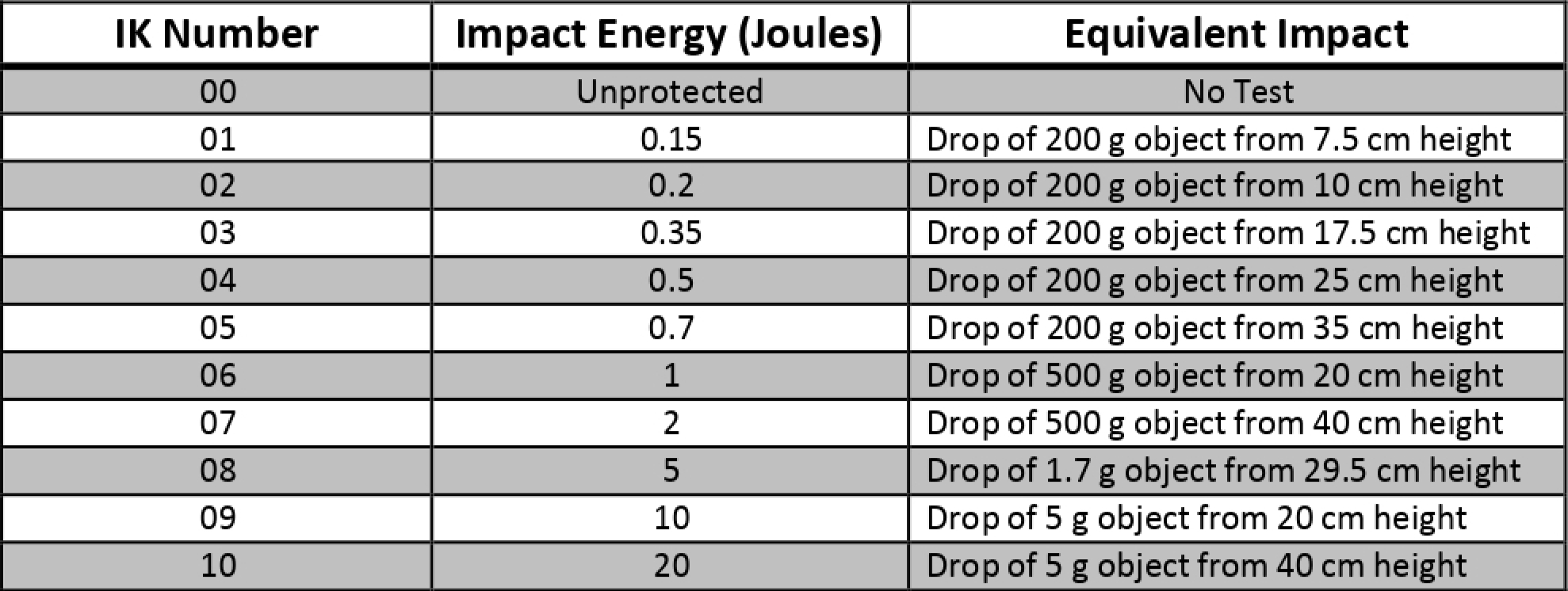

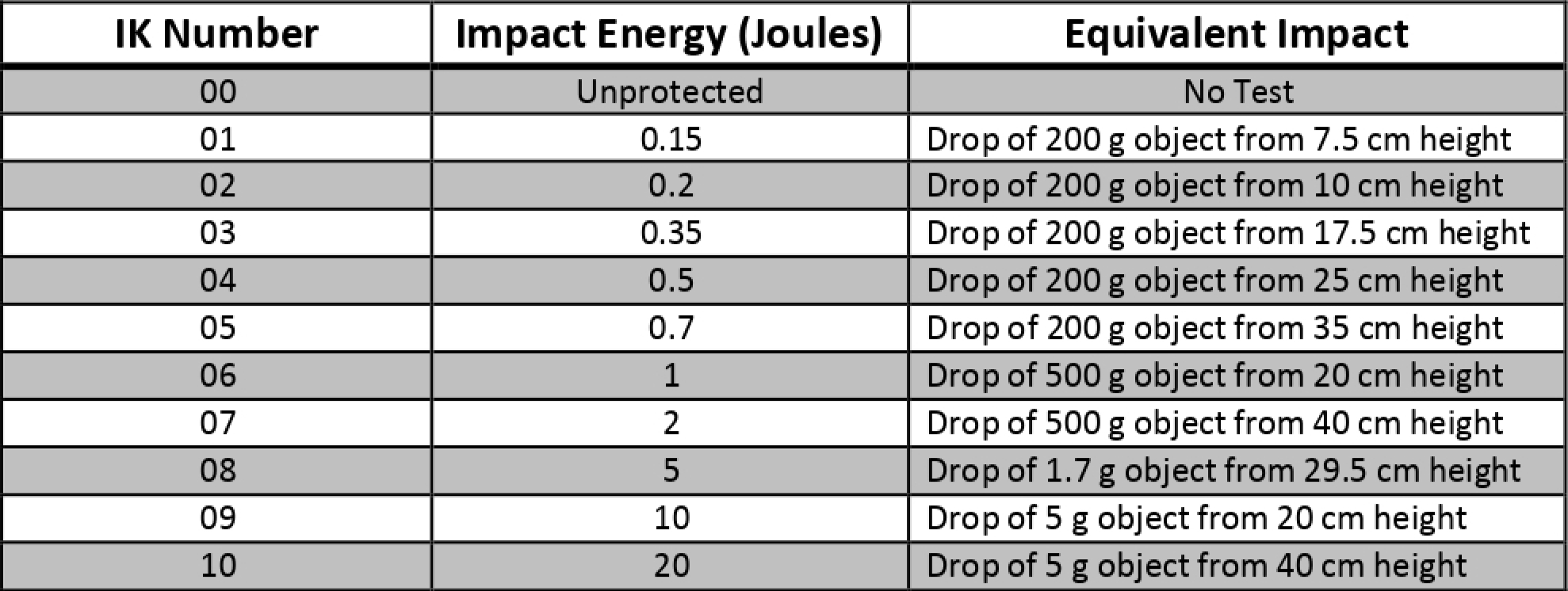

Mechanical Impact Resistance – IP and IK Rating Codes

An additional number is sometimes used to specify the resistance of equipment to mechanical impact. This mechanical impact is defined by the energy needed to qualify a specified resistance level, which is measured in joules (J). These resistance codes typically refer to enclosures and are not typically seen with respect to stepper motors, brush or brushless motors, ac motors, or servo motors, nor are they typically used to define gearmotors or gearboxes. Older enclosure specifications are sometimesseen with an optional third IP digit denoting impact resistance. Newer products are likely to be given an IK rating instead.

Important Note: There is NOT an exact correspondence of values between the old and new standards.

IP69K

German standard DIN 40050‐9 extends the IEC 60529 rating systems described above with an IP69K rating for high‐temperature/high‐pressure wash‐down applications. Again, these ratings typically involve enclosures. These IP69K enclosures must be dust tight (IP6X), and be able to endure high‐pressure steam cleaning, often used in pharmaceutical and food applications.

The high‐temperature/high‐pressure test specifies a spray nozzle that is fed with 80°C water at 8‐10MPa (80‐ 100bar) and a flow rate of 14‐16L/min. The spray nozzle is held 10‐5 cm from the tested device, at several angles: 0°, 40°, 60°, and 90° for 30s each. The test device is placed on a turntable that rotates once every 12s (5RPM) as the test is performed.

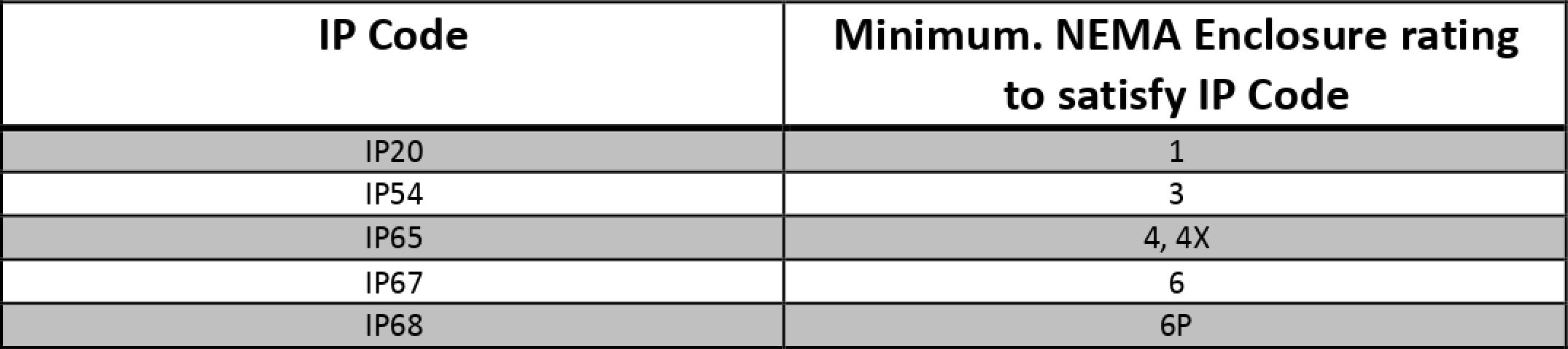

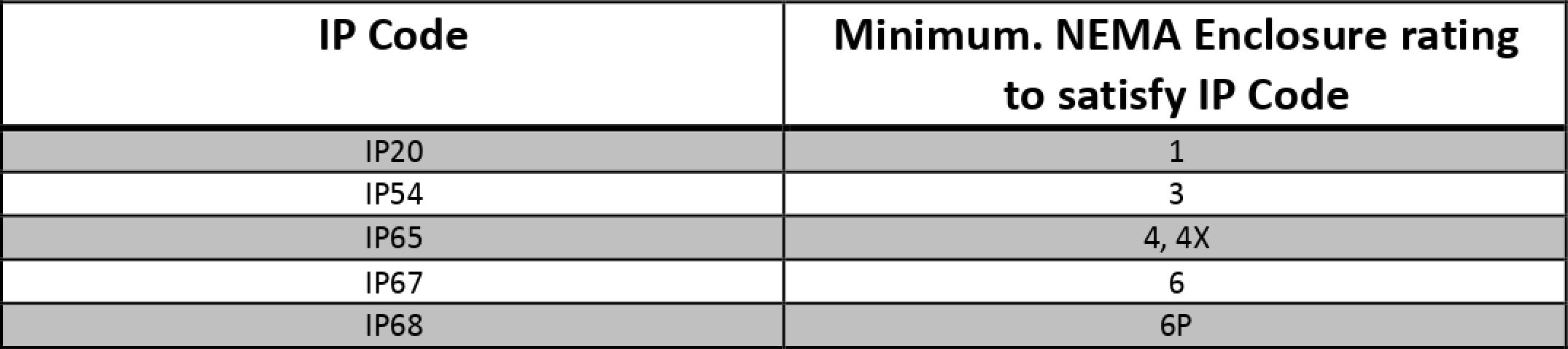

The United States National Electrical Manufacturers Association (NEMA) also publishes protection ratings for enclosuressimilar to the IP rating system published by the International Electrotechnical Commission (IEC). However, NEMA also dictates other product features not addressed by IP codes alone. Important factorssuch as gasket aging, construction practices, and corrosion resistance, are also addressed in NEMA specifications. Even though it may be possible to map IP Codes to NEMA ratings that satisfy or surpassthe IP Code criteria, mapping NEMA ratings to IP Codes is impossible, as the IP Code does not mandate the additional requirements.

Typically, North American enclosure rating systems are defined in NEMA250, UL 50, and CSA C22.2. If your application requires a specific rating, it is advised to check all three entities before deciding on an enclosure. If you are housing Anaheim Automation’s drivers and controllers, please refer to the specifications of each product, as well as the general guidelines provided by Anaheim Automation.

NEMA Rating (enclosures)

NEMA terms defined:

NEMA 1 enclosures are typically used for protecting controls and connections/terminations from objects and personnel. This style of enclosure, while offering a latching door, does not have a gasket sealing surface. NEMA 1 enclosures are typically used in applications where sealing out dust, oil, and water is not required. Motor start/stop stations are often housed in NEMA 1 enclosures.

NEMA 3R enclosures are typically used in outdoor applicationsfor wiring and junction boxes. This style of enclosure provides protection against falling rain, sleet, snow, and external ice formation. Indoors they protect against dripping water. This style of enclosure does not have a gasketsealing surface. Some NEMA 3R models have hasps for padlocking.

NEMA 3S enclosures are intended for outdoor use primarily to provide a degree of protection against windblown dust, rain, sleet, and to provide for operation of external mechanisms when ice laden.

NEMA 4 enclosures are used in many applications where an occasional wash‐down operation occurs or where machine tool cutter coolant is used. NEMA 4 enclosures also serve in applications where a pressurized stream of water will be used. NEMA 4 enclosures contain gaskets, and the door of the enclosure is clamped for maximum sealing. They have continuous hinges, mounting feet, and padlock hasps. NEMA 4 enclosures are available in sizes from small wall mounts to two‐door floor mount enclosure models.

NEMA 4X enclosures are made of stainlesssteel or high‐quality plastics. NEMA 4X enclosures are typically used in harsher environmentsthan the standard NEMA 4 types. Applications where corrosive materials and caustic cleaners are used necessitate the use of a NEMA 4X enclosure. Applicationsinclude food, such as meat/poultry processing facilities, wherein total wash‐down operations using disinfectants are a necessity for safety. These operations occur repeatedly,such as in petro‐chemical facilities, including offshore petroleum sites. NEMA 4X is used when protection from the worst environmentsis required. NEMA 4X enclosures are available in sizes from small wall mounts to two‐door floor mount models.

NEMA 6P enclosures are intended for both indoor and outdoor use, primarily to provide a degree of protection against the entry of water during prolonged submersion at a limited depth.

NEMA 12 enclosures are designed to prevent the ingress of dust, water, and oil. Note: NEMA 12 enclosures are most often used for indoor applications of automation control and electronic drivessystems. Some examples are packaging, material handling, non‐corrosive process control, and manufacturing applications. Doors with gasketsseal the enclosure's contents from airborne contaminants and non‐pressurized water and oil. NEMA 12 enclosures are available in sizes from small wall mounts to two‐door floor mount models.

NEMA 13 enclosures are intended for indoor use primarily, to provide a degree of protection against dust, spraying of water, oil, and non‐corrosive coolant.

IP Ratings Quick Reference Chart

Motor Frame Number and Letters

The information below is based on information contained in the NEMA Standards Publication, "Information Guide for the General Purpose Industrial AC Small and Medium Squirrel‐Cage Induction Motor Standards".

When calling Anaheim Automation to replace a motor, information from the nameplate or label of the motor in question is helpful,starting with the frame number. What does this “frame” number mean? When replacing a motor, important mounting information is associated with this number. Motors of the same frame number, regardless of the manufacturer, will replace another motor with the same frame number, as long as it is the same technology (i.e. stepper, servo, BLDC, brush, ac motor types) and the specifications match. It is just one of the standards of the National Electrical Manufacturers Association (NEMA).

The frame number for very small motors(those with just two numbers) when divided by 16, will give the shaft height of the motor.

For medium motors (those with three or four numbers), the shaft height is found by dividing the first two numbers of the frame number by four. This may not be essential in replacing a motor, but it can be very helpful in new installations. If one knows the frame number of the motor that is going to be installed, the shaft height can be determined and progress toward proper alignment can be started before the motor is placed in position. For stepper motors, the frame size roughly correlate to the diameter of the motor (in inches). For example, a NEMA 23 frame stepper motor is approximately 2.3 inches in diameter, whereas a NEMA 42 would be approximately 4.2 inches in diameter.

They may also be letters associated with the motor frame numbers. These letters denote variations in the frame configuration, and can make a difference in the mounting of the motor. These letters can cause some confusion in knowing whether or not a new motor can be used as a replacement. The letters C, H, Y and Z may immediately follow the frame number in the small motors. These letters are used to denote the following variations of the motor:

Small Motors

C = C‐face mounting type

H = Indicates a frame having an F dimension (bolt mounting pattern) larger than that of the same frame without the suffix letter H

Y = Special mounting dimensions(obtained from the manufacturer)

Z = All mounting dimensions are standard except the shaft extension.

Medium Motors‐ the letters C, CH, D, R, S, T, U, V, Y, or Z may immediately follow the frame number.

These letters are used to denote the following variations of the motor.

C = C‐ face type mounting on drive end. (When the face mounting is at the end opposite the drive, the prefix F shall be used, making the suffix letters FC)

CH = C‐ face type mounting dimensions are different from those for the frame designation having the suffix letter C (The letters CH are to be considered as one suffix and shall not be separated)

D = D flange mounting on the drive end. (When the flange mounting is at the end opposite the drive, the prefix F shall be used, making the suffix letters FD)

R = Drive end tapered shaft extension

S = Standard short shaft for direct connection

T = Included as part of a frame designation for which standard dimensions have been established

V = Vertical mounting only

Y = Special mounting dimensions(obtained from motor manufacturer)

Z = All mounting dimensions are standard except the shaft extension(s). Sometimes used to designate motors with a double shaft extension.

Motor Identification

In most instances, the following information will help an Anaheim Automation Customer Service Rep or Applications Engineer identify a motor:

-

- Motor frame designation (actual frame size in which the motor is built).

- Overall motor length, not including the shaft

- Torque, power and speed

- Design and enclosure type

- Voltage, frequency and number of phases of the powersupply

- Class of insulation and time rating.

- Number of wires and/or terminals

- Application the motor is being used

- Single or double‐ended shaft configuration

- Check the motor label or nameplate for a manufacturer and specification

NOTE: The more information provided, the closer Anaheim Automation can cross to an equivalent motor.

Explosion‐Proof‐ U.L. Classificationsfor Specialty Motors(Underwriter's Laboratories)

CLASS I ‐ Those in which flammable gasses or vapors are or may be present in the air in quantitiessufficient to product explosive or ignitable mixtures.

Group C ‐ Atmospheres containing ethyl or ether vapors.

Group D ‐ Atmospheres containing gasoline, hexane, benzine, butane, propane, alcohol, acetone, benzol, lacquer solvent vapors, natural gas, etc.

CLASS II ‐ Those which are hazardous because of the presence of combustible dust

Group E ‐ Atmospheres containing metal dust, including aluminum, magnesium, or their commercial alloys.

Group F ‐ Atmospheres containing carbon black, charcoal, coal or coke dust.

Group G ‐ Atmospheres containing flour, starch, grain or combustible plastics or chemical dusts.

Explosion‐Proof Enclosures

Totally enclosed, this enclosure is constructed to withstand an explosion of a specified gas, vapor or dust which, may occur within it. Should such an explosion occur, the enclosure would prevent the ignition or explosion of the gas or vapor which may surround the motor enclosure. These motors are listed with Underwriter's Laboratories.

Explosion‐Proof‐ HAZARDOUS LOCATIONS

DIVISION I ‐ Locationsin which ignitable concentrations of flammable or combustible material exist and come in contact with the motor.

DIVISION II ‐ Locationsin which ignitable concentrations of flammable or combustible material exist, but are contained within closed systems or containers and normally would not come in contact with the motor.

Motor Temperature Considerations

Externally Ventilated Motors

A motor using an external cooling system. This is required in applications where the motor's own fan will not provide sufficient cooling. These cooling systems are used in certain duty cycle applications, with slow speed motors, or in environments with extreme dirt. Often a duct with an external blower is used to bring clean air into the motor's air‐intake.

Motor Temperature – See specifications, as it will vary depending on the model

Temperature has a direct effect on a motor’s overall life expectancy. These following factors should be taken into considerations, as they will affect a motor's operating temperature. Failure to address these aspects of a given application can cause poor system performance, as well as total motor failure.

-

- Bearings Used

- Lubricants Used

- Duty Cycle of the Application

- Radial Loading

- Axial Loading

- Mounting and Heat sinks

- Enclosure Material

- Ambient Temperature

- Ventilation ‐ Airflow

NOTE: As a general rule, each 10 degrees C increase in the total temperature over the maximum permissible to the motor'sinsulation system, reducesits life expectancy by half. Bearing or gear lubricant life is reduced by half for every 25 degrees F (approximately 14 degrees C) increase in temperature. Heat eventually causes deterioration of most lubricants and sealsleading to leakage and increased friction.

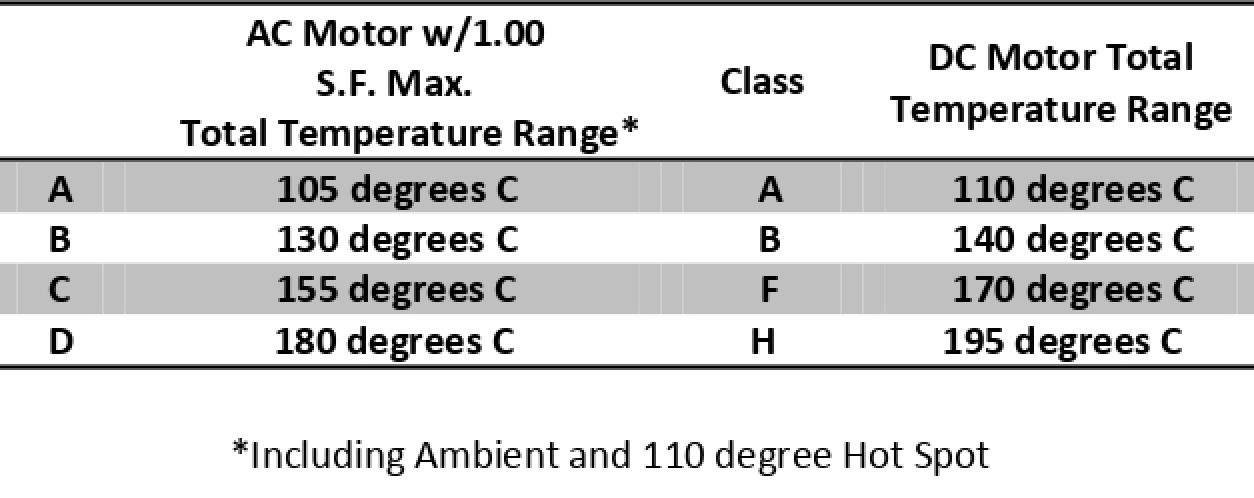

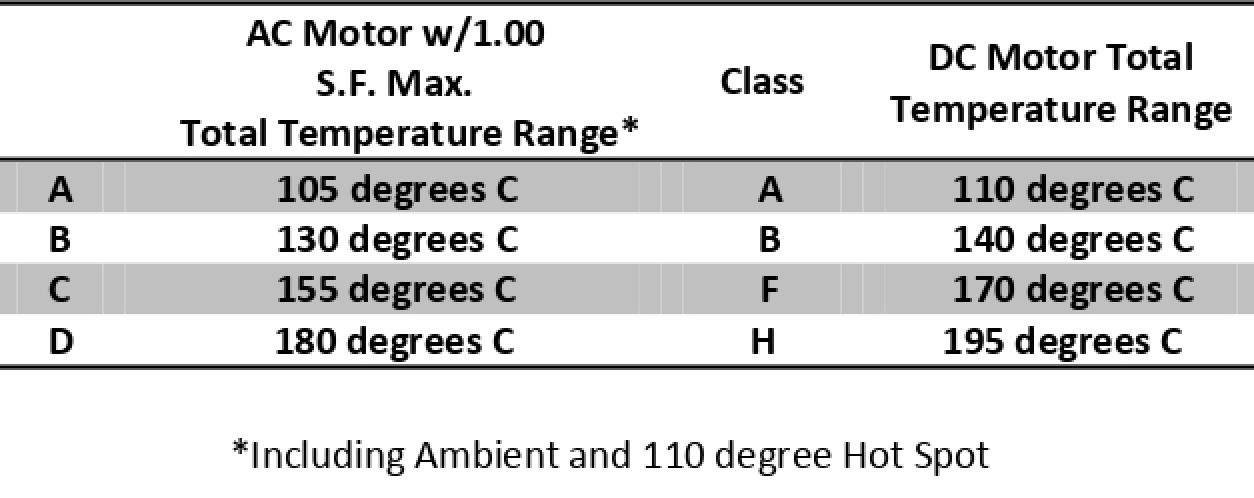

Motor Insulation Class

There are various ambient temperature conditions a motor might encounter and different temperature ranges within which a motor will run. Therefore, motor insulation is also sensitive to temperature and classified by the temperature ranges at which it can safely operate for a sustained period of time.

There are four common classes:

NOTE: When a motor insulation classis labeled on the manufacturer’s nameplate/label,the total insulation system is capable of sustained operation at the above temperature. CAUTION – Motor Surface Temperatures can be very hot. Depending upon the design and cooling arrangements, the motor’s surface can be high enough to be very uncomfortable to the touch. These temperatures do not necessarily indicate overload or impending motor failure.

Lubrication

For certain motor components, lubrication is required (application of an oil or grease), in order to reduce wear and avoid overheating. The bearings are the major motor component requiring lubrication. Always consult the manufacturer'sinstructions and note that excess lubrication can damage the motor windings and bearings.

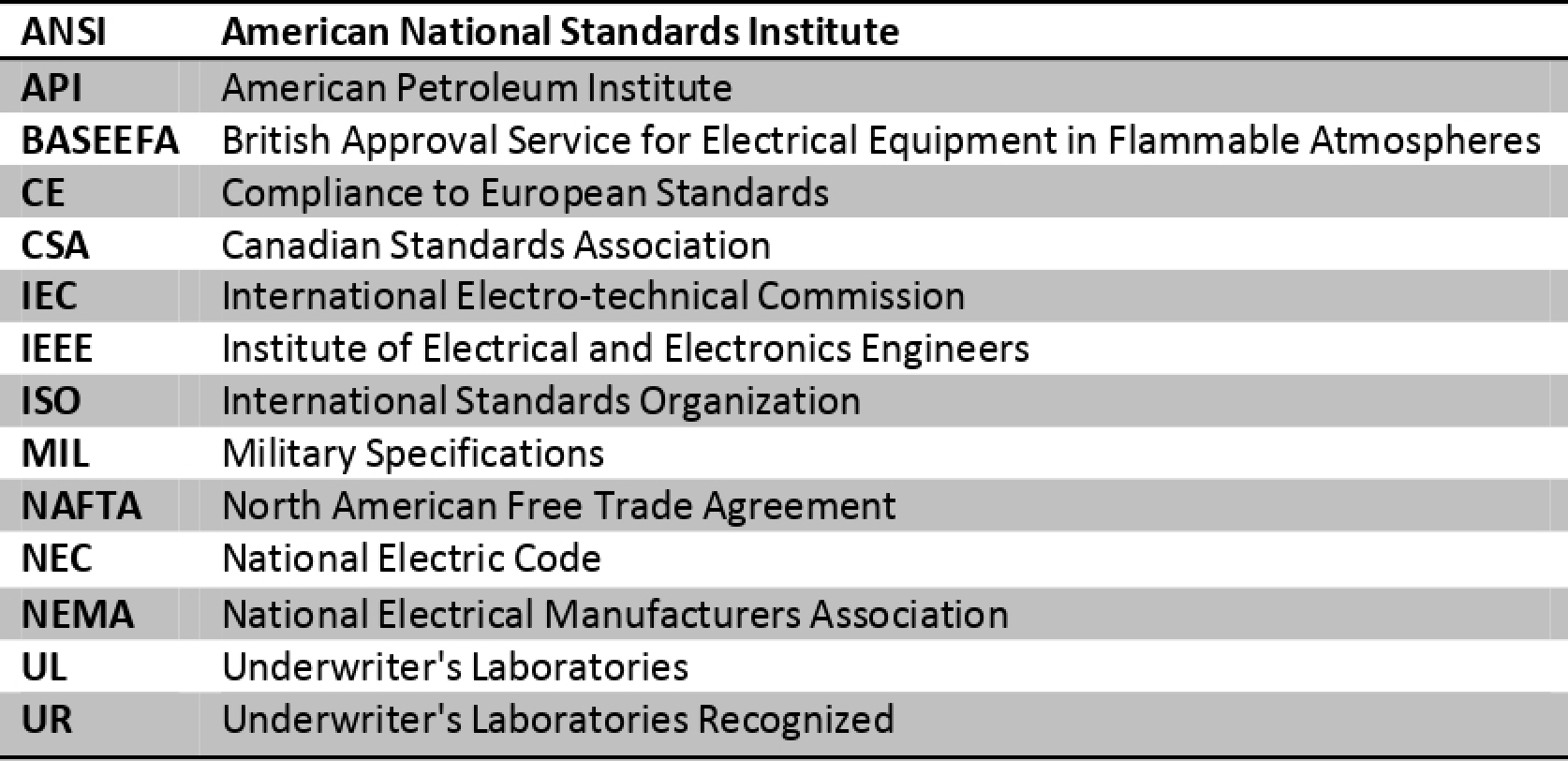

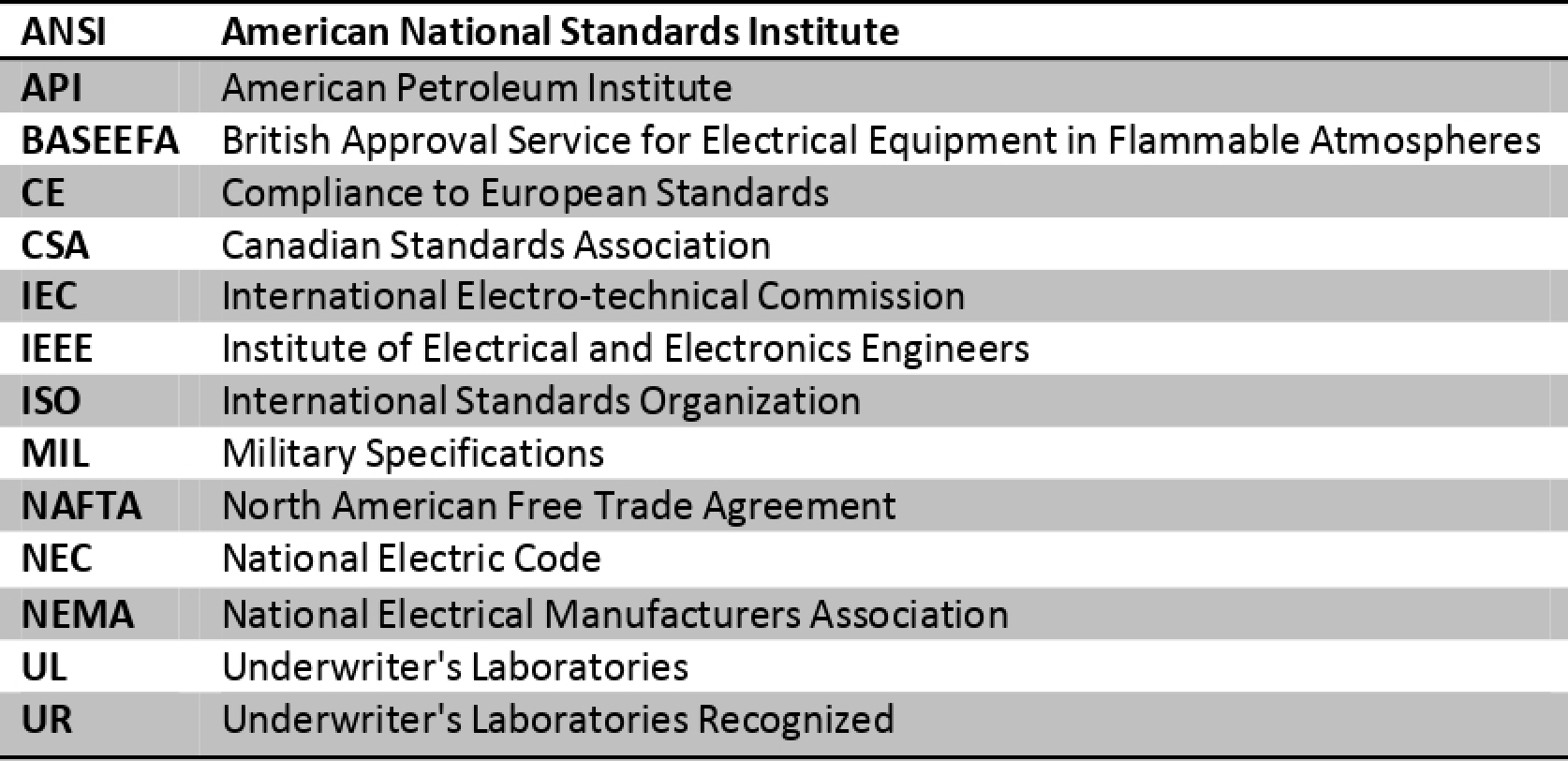

Other STANDARDS Organizations