We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Selecting a Stepper Motor System

Selecting a Stepper Motor System

What is a Stepper Motor?

A stepper motor (or otherwise referred to as a step or stepping motor) is a digital device, in that digital information is processed to accomplish an end result, which is controlled motion. A stepper motor is most commonly used for position control. With a stepper motor /driver/controller system design, it is assumed that the stepper motor will faithfully follow digital instructions. It is an open-loop system, sometimes making it more affordable than other motion control designs.

Where Are Stepper Motors Used?

Although the stepper motor is sometimes overshadowed by servo systems for motion control applications, it now is emerging as the preferred technology in more and more areas. Stepper motor applications are all around us: used in printers (paper feed, print wheel), disk drives, X-Y plotters, clocks and watches, as well as in factory automation, CNC, packaging machinery, labelers, medical diagnostic equipment, aircraft controls, camera and security systems… wherever position control is required.

Benefits of Stepper Motor Technology

• Cost Efficient

• Simple designs

• Highly reliable

• Brushless construction

• Maintenance –free

• No feedback mechanisms required

• High acceleration and power rate

• Known limit to the dynamic position error

How Does a Stepper Motor Work?

A stepper motor is an electromagnetic, rotary, incremental actuator which converts digital pulses into mechanical shaft rotation. In essence, stepper motors are driven by digital pulses rather than a continuously applied voltage. The pulse (usually called a clock signal or step signal) used in a stepper motor system can be generated by most microprocessors, timing logic, or even a switch or relay closure. A train of pulses translates into shaft revolutions, with each revolution requiring a given number of pulses. Each pulse equals one rotary increment or step (hence, step, stepper, stepping motor). Each step is only a portion of one complete rotation. A system designer must choose the desired step angle, as this will vary depending upon the stepper motor type. Sending and counting pulses is applied to achieve a desired amount of shaft rotation. The count automatically represents how much movement will be achieved. A stepper motor/driver/controller system is typically designed without the need for feedback information, as would be the case in servo systems. If an encoder is desired, a stepper motor may be added to the rear shaft of the stepper motor (series and model dependent). For a stepper motor application that requires an encoder, be certain to order a double-ended shaft motor.

Summary:

• One Pulse Equals One Step

• Pulse Count Equals Step Count

• One Full Step Equals Two Half Step

NOTE: Anaheim Automation can provide an encoder as an "adder" to most stepper motor series in its product line. To be certain you order the correct stepper motor and encoder combination, contact a sales representative, or visit the Accessories pages on our website for encoder adders.

Precision of stepper motor controlled motion is determined primarily by the number of steps per revolution; the more steps, the greater the precision. For very precise movements, some stepper motor drivers divide normal steps into half-steps or micro-steps. Anaheim Automation offers stepper motor drivers in full-step and half-step, as well as microstep drivers up to a 256 divisor.

NOTE: Accuracy of the stepper motor is a function of the mechanical precision of its parts and the assembly techniques. Most stepper motors fall into the 3% per step range. Whatever error that may be built into a stepper motor, it is noncumulative. Consequently, it is often considered negligible.

Think of a stepper motor as an electromagnetic, rotary actuator that mechanically converts digital pulse inputs to incremental shaft rotation. The rotation not only has a direct relation to the number of input pulses, but its speed is related to the frequency of these pulses.

Between steps, the stepper motor can hold its' position (and its' load) without the aid of clutches or brakes. Therefore, a stepper motor can be precisely controlled, rotating a designated number of steps, producing mechanical motion through a specific distance, holding its load when it stops. A stepper motor will repeat the operation any prescribed number of times.

Selecting a Stepper Motor

Selecting a stepper motor and using it to its full advantages depends on three important criteria:

1. Desired mechanical motion

2. Speed required

3. Load

With the appropriate logic, stepper motors can be bi-directional, synchronous, provide rapid acceleration, stopping, and reversal, and will interface easily with other digital mechanisms. Characterized as having low rotor moment of inertia, no drift, and a noncumulative positioning error, a stepper motor is a cost-effective solution for many motion control applications. Generally stepper motors are operated without feedback in an open-loop fashion and sometimes match the performance of more expensive DC Servo Systems. As mentioned earlier, the only inaccuracy associated with a stepper motor is a noncumulative positioning error measured in % of step angle.

Motion requirements, load characteristics, coupling techniques, and electrical requirements need to be understood before the system designer can select the best stepper motor/driver/controller combination for a specific application. While not a difficult task, several key factors need to be considered when determining an optimal stepper motor solution. The system designed should adjust the characteristics of the elements under his/her control, to meet the application requirements. Anaheim Automation offers many options in its broad line of stepper motor products, allowing the maximum amount of design flexibility. Although it may appear overwhelming to choose, the result of having a large number of options is a high-performance system that is cost-effective. Key elements that must be considered carefully include the stepper motor, driver, and power supply selections, as well as the mechanical transmission, such as gearing or load weight reduction through the use of alternative materials. Some of these relationships and system parameters are described in this guide.

Inertial Loads – Inertia is a measure of an object's resistance to a change in velocity. The larger an object's inertia, the greater the torque is required to accelerate or decelerate it. Inertia is a function of an object's mass and shape. A system designer may wish to select an alternative shape or low-density material for optimal performance. If a limited amount of torque is available in a selected system, then the acceleration and deceleration times must increase. For the most efficient stepper motor system, the coupling ratio (gear ratio) should be selected so that the reflected inertia of the load is equal to, or greater than, the rotor inertia of the stepper motor. It is recommended that this ratio not be less than 10 times the rotor inertia. The system design may require that the inertia be added or subtracted by selecting different materials or shapes of the loads. NOTE: The reflected inertia is reduced by a square of the gear ratio, and the speed is increased by a multiple of the gear ratio.

Frictional Loads – All mechanical systems exhibit some frictional force. The designer of a stepper motor system must be able to predict elements causing friction within the system. These elements may be in the form of bearing drag, sliding friction, system wear, or the viscosity of an oil filled gear box (temperature dependent). A stepper motor must be selected that can overcome any system friction and still provide the necessary torque to accelerate the inertial load. NOTE: Some friction is desired, since it can reduce settling time and improve performance.

Positioning Resolution – The positioning resolution required by the application may have an effect on the type of transmission used, and/or selection of the stepper motor driver. For example: A leadscrew with 5 threads per inch on a full-step drive provides 0.001 inch/step; half-step provides 0.0005 inch/step; a microstep resolution of 25,400 steps/rev provides 0.0000015 inch/step.

Basic Types of Stepper Motors: Variable Reluctance, Permanent Magnet, Hybrid

The construction of the stepper motor includes a permanent magnet and/or an iron rotor with a laminated steel stator. The basic types of stepper motor are:

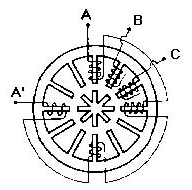

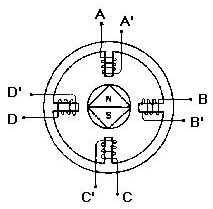

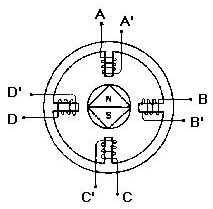

Variable Reluctance (VR) - VR stepper motors are characterized as having soft iron multiple rotors and a wound stator. They generally operate with step angles from 5 degrees to 15 degrees at relatively high step rates, and have no detent torque (detent torque is the holding torque when no current is flowing in the motor). In Figure 2, when phase A is energized, four rotor teeth line up with the four stator teeth of phase A by magnetic attraction. The next step is taken when A is turned off and phase B is energized, rotating the rotor clockwise 15 degrees; Continuing the sequence, C is turned on next and then A again. Counter clockwise rotation is achieved when the phase order is reversed.

NOTE: Anaheim Automation does not carry any VR stepper motors.

Permanent Magnet (PM) - PM stepper motors differ from VR stepper motors by having permanent magnet rotors with no teeth that are magnetized perpendicular to the axis. In energizing the four phases in sequence, the rotor rotates as it is attracted to the magnetic poles. The stepper motor shown in Figure 6 will take 90 degree steps as the windings are energized in sequence ABCD. PM's generally have step angles of 45 or 90 degrees and step at relatively low rates, but they exhibit high torque and good damping characteristics. Anaheim Automation carries a wide selection of PM stepper motors, ranging from 15 to 57mm in diameter.

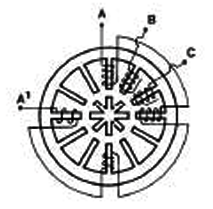

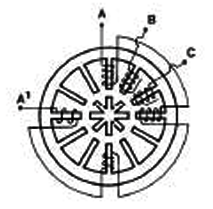

Hybrid - Combining the qualities of the VR and the PM stepper motor design, the hybrid stepper motor has some of the desirable features of each. A hybrid stepper motor has high detent torque and excellent holding and dynamic torque. Additionally, the hybrid stepper motor can operate at high stepping speeds. Normally, hybrid stepper motors are designed with step angles of 0.9°, 1.8°, 3.6° and 4.5°; 1.8 degrees is the most common. Bi-filar windings are generally supplied (as depicted in Figure 4), so that a single-source power supply can be used in hybrid stepper motor systems. If the phases are energized one at a time, in the order indicated, the rotor would rotate in increments of 1.8 degrees.

NOTE: At Anaheim Automation, the 1.8 degree hybrid stepper is the most widely stocked stepper motor type, and ranges in size from NEMA frame sizes 08 to 42. The hybrid stepper motor can also be driven two phases at a time to yield more torque, or alternately one then two then one phase, to produce half-steps or 0.9 degree increments.

Motor Windings

Stepper motors are wound on the stator poles in either a unifilar or bifilar configuration. A brief explanation of each follows:

The term Unifilar winding refers to the winding configuration of the stepper motor where each stator pole has one set of windings; the stepper motor will have only 4 lead wires. This winding configuration can only be driven from a bipolar driver.

The term Bifilar winding refers to the winding configuration of a stepper motor where each stator pole has a pair of windings; the stepper motor will have either 6 or 8 lead wires, depending on termination. This wiring configuration can be driven from a unipolar or bipolar driver.

Stepper Motor Heating Issues

It is normal for a stepper motor to run hot (50 – 90° C). The maximum allowable temperature of the motor case should be specified by the motor manufacturer. Motor power is limited by the maximum allowable temperature of the stepper motor insulation. Class "B" Insulation stepper motors have maximum temperature ratings of 150°C. Therefore, Class "B" motors are typically rated with case temperatures of 90° -100°C after allowance for expected ambient temperatures. Higher class insulation can normally be specified to allow stepper motors to run hotter if required.

To help reduce stepper motor heating, Anaheim Automation provides "No Power" on its entire line of stepper motor drivers and "Low Power" provisions for its microstep drivers when the stepper motor is in standstill state. This method, plus proper mounting and heatsinking methods, will help the stepper motor run cooler and within the acceptable range of its insulation class.

How Are Stepper Motors Controlled?

A stepper motor driver acts to convert the logic pulses by sequencing power to the stepper motor windings; generally, one supplied pulse will yield one rotational step of the motor. A driver provides precise, controllable speed and positioning. The stepper motor increments (moves) a precise amount with each control pulse, converting digital information to exact incremental rotation, without the need for feedback devices such as tachometers or encoders. Because the stepper motor/driver system is open loop, the problems of feedback loop phase shift and resultant instability, common with servo motor/drive systems, are eliminated.

Performance Factors of a Stepper Motor and Driver System

One of the most important aspects affecting stepper motor performance is the driver circuitry. The stepper motor driver design factors include power delivered to the motor, efficiency, and power dissipation. The basic objective of driver circuitry for high-speed operation is to provide a high voltage to move current into and out of the winding at pulse transition, and a low voltage to sustain only the correct current during the steady-state portion of the current pulse. Overall, system performance is dependent upon the capabilities of the stepper motor driver to supply the required voltage and amperage (power) to the stepper motor.

Torque Requirement – Stepper Motor

When sizing a stepper motor system, the designer must calculate the maximum torque requirement for the application. This is typically the total torque required during the acceleration portion of the motion. Since the torque of a stepper motor decreases as the speed increases, the application may have an effect on the transmission selected. A design safety factor – or torque margin – should be utilized to make certain that the stepper motor system will deliver more torque than is absolutely required. The design safety factor should be able to accommodate mechanical wear, extra loads, lubrication hardening, and any other mechanical factors of the stepper motor motion control design.

THE TIP: With respect to sizing/torque of a stepper motor, a design safety factor of 1.25 to 2.5 is ideal. It is not recommended to have large excess of torque, as the excess may cause the mechanical system to resonate and wear out prematurely. Greatly over-sizing a stepper motor will add to the overall cost and actually decrease system performance.

Selecting A Stepper Motor Driver

Amount, speed, and direction of rotation of a stepper motor are determined by the appropriate configurations of digital control devices. Selecting the most compatible stepper motor, driver, and/or controller, can save the user money and be a less cumbersome motion control solution. Anaheim Automation categorizes the major types of digital control devices as:

• Stepper Motor Drivers – offered in full-step, half-step and micro-step

• Stepper Motor Controllers (sometimes referred to as Control Links – controllers indexers, and pulse generators sold separately or in Drivers Packs

• Stepper Motor Driver Packs – packaged units that include drivers and optional controller, with a matched power supply (most models are enclosed units that are fan-cooled)

• Integrated Stepper Motor/Driver/Controllers – packaged at the end of a stepper motor are drivers and simple controllers (only available for high-torque stepper motors)

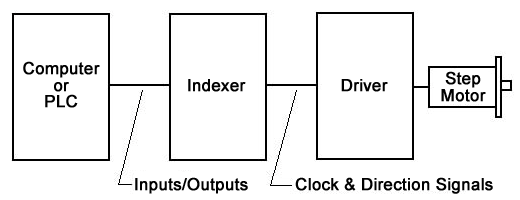

These devices are employed as shown in Figure 5. The stepper motor driver accepts clock pulses and direction signals and translates these signals into appropriate phase currents in the stepper motor. The Indexer creates the clock pulses and direction signals, "translates" them into power to energize the stepper motor windings. The computer or PLC (programmable logic controller) sends commands to the indexer/controller.

Load characteristics, performance requirements, and mechanical design including coupling techniques must be thoroughly considered before the designer can effectively select the most suitable stepper motor and driver combination for a specific application. Failure to do so may result in poor system performance, or cost more than necessary. The following factors must be considered in order to obtain an optimum stepper motor motion control solution:

1. Parameters to be considered for a stepper motor system:

a) Distance – The distance to be traversed to complete the motion.

b) Time – The maximum time allowed for a traverse.

c) Accuracy – The desired detent (static) accuracy.

d) Overshoot – The desired dynamic accuracy (overshoot).

e) Settling Time - The time allowed for dynamic accuracy to return to static accuracy specification (settling time).

f) Step Resolution – The required step resolution (combination of step size, gearing, and mechanical design).

g) Friction – The system friction: All mechanical systems exhibit some frictional force. When sizing the stepper motor, remember that the motor must provide torque to overcome any system friction. A small amount of friction is desirable since it can reduce settling time and improve performance.

h) Inertia - System inertia: An object's inertia is a measure of its resistance to changes in velocity. The larger the inertial load, the longer it takes a stepper motor to accelerate or decelerate that load. The speed at which the stepper motor rotates is independent of inertia. For rotary motion, inertia is proportional to the mass of the object being moved times the square of its distance from the axis of rotation.

i) Speed/Torque – There a specific speed/torque characteristics to each stepper motor, which will determine your overall system performance. Torque is defined as rotational force (in ounce-inches) defined as a linear force (in ounces) multiplied by a radius (in inches).

IMPORTANT NOTE: When selecting a stepper motor/driver, the capacity of the stepper motor must exceed the overall requirements of the load. The torque any stepper motor can provide varies with its speed. Individual speed/torque curves should be consulted by the designer for each application.

j) Torque-to-Inertia Ratio - This number (ratio) is defined as a stepper motor's rated torque divided by its rotor inertia. This ratio (measurement) determines how quickly a stepper motor can accelerate and decelerate its own mass.

NOTE: Stepper motors with similar torque ratings can have different torque-to-inertia ratios as a result of varying construction. Performance will vary among different manufacturers.

k) Torque Margin: Whenever possible, a stepper motor drive that can provide more torque than is absolutely necessary should be specified. Torque margin allows for mechanical wear, lubricant hardening, and other unexpected friction. Resonance effects can cause the motor's torque to be slightly lower at some speeds. Selecting a stepper motor drive that provides at least 50% margin above the minimum required torque is ideal. More than 100% may prove too costly.

2. Calculation - It is critical to obtain accurate system measurements of inertia, friction and workloads reflected to the stepper motor.

a) In an open-loop stepper motor drive system, the stepper motor does not "know" if excessive inertia or friction has made the stepper motor lose or gain one or more steps, thus affecting the positional accuracy.

b) Load inertia should be restricted to no more than four times motor rotor inertia for high performance (relatively fast) systems. A low performance system can deliver step accuracy with very high inertia loads, sometimes up to ten times rotor inertia. System friction may enhance performance with high inertia loads.

Experimentation: Tailoring

Please be advised that experimentation for stepper motor sizing is almost always necessary because of dynamic changes in system friction and inertia, (load anomalies) that may be difficult to calculate. Stepper motor resonance effects can also change when the stepper motor is coupled to its load. At Anaheim Automation, we encourage customers to experiment with several stepper motor options for optimal system performance.

Types of Stepper Motor Drivers

The basic function of a stepper motor driver is to provide the rated motor phase current to the stepper motor windings in the shortest possible time. When a stepper motor is running, the rate of current change through the windings is critical for optimal speed and torque. Inductance is the force which current must overcome to flow faster. The lower the inductive time constant of the stepper motor, the faster current will flow. While an infinite number of drive circuits have been devised to create a lower inductive time constant, they all fall into three basic stepper motor driver categories which are L/R, bilevel, and PWM chopper (microstep):

L/R Stepper Motor Drivers – Resistance Limited

The L/R stepper motor driver design was the basis for most of the older drive designs. This drive technique provides for full/half step operation, but does not permit variable control of current level. Stepper motors driven by L/R drivers produce low to moderate system performance. Therefore, L/R drivers are typically used for replacement in older stepper motor systems. At Anaheim Automation, we do not suggest L/R stepper motor drivers for new motion control applications/systems. L/R stepper motor drivers are low-performing drivers in that the full rated running torque is provided only at low to moderate speeds, resulting in limited power output. However, the speed and power output may be entirely adequate for some low speed applications. Resistance limited, or L/R drivers, use dropping resistors to match the motor to the power supply. These resistors are usually placed in series with the common leads of the stepper motor. Their resistance should be calculated based upon the stepper motor phase current and voltage ratings. When moderate to high torque and speed are required, L/R driver circuits are rather inefficient.

CAUTION: Considerable heat may be generated in resistors that are part of the circuitry involved (can burn skin if touched). The required power supply and dropping resistors may be rather bulky; another reason that makes the L/R stepper motor driver less than ideal. These factors must be taken into account before selecting the type of stepper motor driver to be used.

NOTE: In more successful L/R stepper motor driver applications, performance requirements are low enough (i.e. low speed operation) to preclude the need for dropping resistors altogether. In these applications, the stepper motor phase voltages often range from 5 to 35 volts with correspondingly low to very low phase currents. These applications make up the bulk of the practical uses for L/R stepper motor drivers.

Bilevel Stepper Motor Drivers

The bilevel stepper motor driver uses two voltages: high and low. The bilevel driver uses a high voltage to obtain a rapid rate of current rise time in the stepper motor windings. When the appropriate operating current level is reached, the driver turns off the high voltage and sustains the current level from a low voltage supply, hence the term bilevel. While the stepper motor is stepping, the high voltage drives the current into the windings, supplying more of the required current as the stepping rate increases. This low-high-low voltage switching scheme results in higher efficiency and lower cost than that obtainable from choppers and other more exotic schemes. The bilevel stepper motor driver eliminates the need for dropping resistors, but it is somewhat more expensive to design and build. Due to its popularity of the bilevel stepper motor driver, the pricing is now quite cost-effective overall. Also, bilevel stepper motor drivers do not have motor heating problems or RFI and EMI problems that are associated with chopper type drivers.

NOTE: Bilevel drivers can only drive stepper motors in the half-step or full-step mode. If smoothness is critical to your application, you may need to consider a using a microstep driver.

PWM (Chopper) Stepper Motor Drivers - Microstep

PWM (pulse width modulated) stepper motor drivers are also known as chopper or constant current, or microstep drivers. These stepper motor drivers use a single high voltage supply. The stepper motor current is regulated by switching output transistors on and off to achieve an average level of current. These stepper motor drivers have advantages and disadvantages. The most outstanding feature of chopper drivers is the ability to drive stepper motors in a microstep mode. For applications that require smoothness, the microstep driver is the best option. These drivers maintain relatively constant currents to the stepper motr at all speeds, therefore, the microstep driver offers excellent performance. Although typically more costly and complex than the L/R and Bilevel drivers types, microstep drivers such features as current-boost and mid-range stabilization which can prove to be essential for many applications.The disadvantages of chopper drives are that they can produce EMI and RFI, and often have motor heating problems.

Theoretical Microstepping - High microstepping (25,000 - 50,000 steps per revolution) demands quick pulse rates in order to achieve higher speeds. For example, if your microstep resolution is 25,000 steps per resolution, your pulse source must be capable of producing 750,000 pulses per second if it wants to run at a top speed of 1,800 RPM.

TECH TIP: Prior to selecting a step resolution, make sure your pulse generating device can produce step rates high enough to reach the top speed you desire.

The torque available per microstep decreases as the step resolution increases. The following equation explains how the torque available for each microstep is determined:

Torque per microstep = motor holding torque X SIN (90° /microsteps per step).

If the resolution being used is 10,000 steps per revolution with 100 ounce inch motor, then each microstep will generate a torque change of 3.1 oz-in. Increasing the resolution to 50,000 steps per revolution will cause each microstep to produce a torque change of 0.63 oz-in.

If the resolution is 10,000 steps per revolution, with the friction of the load as 3 oz-in., it is expected to get an immediate response to your command to move. Increasing the resolution to 50,000 steps per revolution would take 5 microsteps to be commanded before the torque can build to a level in which it can move the load. This is often called "Empty Stepping," and can be overcome if step resolutions and stepper motor sizes are selected properly.

Unipolar Versus Bipolar

Often a stator pole needs to have the ability to be a North or South pole alternately. The polarity change is simply accomplished by changing the direction of the current flow. In a Unipolar driven stepper motor, each stator pole has two windings, each of which creates one of the two magnetic poles. A Bipolar driven stepper motor has only one winding and each pole is created by reversing the direction of the current flow from the stepper motor driver. The Bipolar driver, while being higher in cost, results in 60% increase in LOW END or LOW SPEED TORQUE, because all of the copper on each stator pole is utilized. Consequently, the Unipolar driver will produce a HIGHER TORQUE at HIGHER SPEEDS. Depending on the application, these characteristics can substantially affect the system performance.

Stepper Motor Driver Excitation Modes - There are three commonly used excitation modes; full-step, half-step, and micro-step. Anaheim Automation offers all three excitation modes (model dependent).

Full-Step Excitation

In full step operation, the stepper motor steps through the normal step angle e.g. 200 step/revolution motors take 1.8 steps while in half step operation, 0.9 steps are taken. There are two kinds of full-step modes. Single phase full-step excitation is where the stepper motor is operated with only one phase energized at-a-time. This mode should only be used where torque and speed performance are not important, e.g. where the stepper motor is operated at a fixed speed and load conditions are well defined. Problems with resonance can preclude operation at some speeds. This mode requires the least amount of power from the drive power supply of any of the excitation modes. Dual phase full-step excitation is where the stepper motor is operated with two phases energized at-a-time. This mode provides good torque and speed performance with a minimum of resonance problems. Dual excitation, provides about 30 to 40 percent more torque than single excitation, but does require twice the power from the drive power supply.

Half-Step Excitation

Half-step excitation is alternate single and dual phase operation resulting in steps one half the normal step size. This mode provides twice the resolution, because instead of moving 1.8° per digital pulse, the motor shaft will move 0.9° (400 steps per revolution, instead of 200 steps per revolution as with full-step mode). While the motor torque output varies on alternate steps, this is more than offset by the need to step through only half the angle. This mode has become the predominately used mode by Anaheim Automation because it offers almost complete freedom from resonance problems. Motors can be operated over a wide range of speeds and used to drive almost any load commonly encountered. Anaheim Automation has a full line of half-step drivers, the most popular being the BLD stepper motor driver series. The product line covers 0.5 Amps to 10 Amps per phase.

Micro-Step Excitation

In the micro-step mode, a stepper motor's natural step angle can be divided into much smaller angles. For example, a standard 1.8° motor has 200 steps/revolution. If the motor is micro-stepped with a 'divide-by-10', then each micro-step would move the motor 0.18 degrees and there would be 2,000 steps/revolution. Typically, micro-step modes range from divide-by-10 to divide-by-256 (51,200 steps/rev for a 1.8° motor). The micro-steps are produced by proportioning the current in the two windings according to sine and cosine functions. This mode is only used where smoother motion or more resolution is required. Anaheim Automation has a full line of micro-step drivers, the most popular being the MBC and MLA stepper motor driver series. The product line covers 0.5 Amps to 10 Amps per phase.

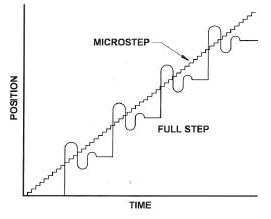

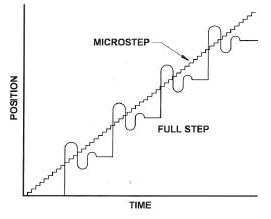

Stepper Motor Settling Time (Ringing) and Resonance

When the stepper motor receives the final pulse signal, (either one or from a continuous train), it will stop rotating. However, complete rest will not occur until all the oscillations have stopped. The time it takes from the application of the last pulse received until the stepper motor comes to a complete rest is known as settling time. (See graph below). Resonance occurs when the stepper motor suddenly makes large oscillations, or the output torque suddenly drops at one certain pulse rate or numerous small regions of pulse rates. The stepper motor will stop (stall), may miss steps or reverse direction from the commanded direction. This phenomenon occurs when the natural frequency of the stepper motor coincides with the frequency of the input pulse rate. This generally occurs around 100 - 200 pulses per second in a full-step operation, and also at higher pulse rates. Microstepping half-step operation, or electrical or mechanical damping, can reduce resonance issues. Microstepping has a large effect on settling time and resonance due to the smaller angular displacement taken per pulse. See Figure below.

Resonance Characteristics

Since a stepper motor system is a discreet increment positioning system, it is subject to the effect of resonance. Where the system is operated at this given frequency, it may begin oscillating. The primary resonance frequency occurs at about one revolution per second. Oscillating will cause a loss of effective torque and may result in a loss of synchronism. Settling time and resonance can be best dealt with by dampening the stepper motor's oscillations through mechanical means. Mechanically, a friction or viscous damper may be mounted on the stepper motor to smooth out the desired motion.

Methods for Changing or Reducing Resonance Points:

• Use of Gearboxes or Pulley Ratios

• Utilize Microstep Drive Techniques

• Change System Inertia

• Accelerate Through Resonance Speed Ranges

• Correct Coupling Compliance

Encoders

Although stepper motors do not require an encoder, Anaheim Automation's double-ended shaft stepper motors are "encoder-ready" as standard construction. Encoders aid in determining whether or not the final position has been achieved. Anaheim Automation indexers contain electronics that allow position correction to be obtained. Although the standard incremental encoder provides 4,000 counts per shaft revolution, this does not limit the step resolution to 4,000. It does mean however, that if an encoder is being used for closed-loop positioning, a "deadband window" would exist. Therefore it is not possible to account for actual "in-between" microsteps.

General Stepper Motor Driver Guidelines

• Driver Output Voltage: Higher voltage will provide better high speed torque

• Stepper Motor Inductance: Higher inductance provides better low speed torque. Lowering inductance is the reverse.

• Smoothness of Operation: Decreasing stepper motor current by 10% below rated will provide smoother operation. Increasing current by 10% below rated will provide more torque, but will cause the stepper motor run "stiffer" or more pronounced ~ the "steps" are more obvious.

• Motor Connection Method (Series or Parallel): Connecting a motor in Series results in 4 times the inductance as compared to a Parallel connection. The result is that Series connection will provide low speed performance and less motor heating, while Parallel will provide high speed performance and an increase in motor heating.

General Stepper Motor Driver Safety Considerations

The following safety considerations must be observed during all phases of operation, service and repair. Failure to comply with these precautions violates the safety standards of design, manufacture and intended use of the product(s). Anaheim Automation assumes no liability for the customer's failure to comply with these requirements, and advises the misuse of its stepper motor products will void the warranty. Even well-designed and manufactured products, operated and installed improperly, can be hazardous. Safety precautions must be observed by the user with respect to the load and operating environment. Described briefly are general Safety Considerations. Please refer to the Environment Consideration's Guide for more details.

• Use caution when handling, testing, servicing and adjusting during all phases of installation and operation of a stepper motor system

• No service/maintenance should be performed with power applied

• Exposed circuitry should be properly guarded or enclosed to prevent unauthorized human contact with live circuitry

• Stepper motor/drivers/controllers should be securely mounted and adequately grounded

• Provide adequate air flow and heat dissipation for all stepper motor system components

• Do not operate a stepper motor system in the presence of flammable gases, dust, vapor or liquids

IMPORTANT NOTE: The customer is responsible for the proper selection, installation, and operation of the stepper motor products purchased from Anaheim Automation. The customer must determine the fitness of selected products for a specific application. Although it is the company's intention to provide sound advice and accurate documentation, Anaheim Automation assumes no liability in the suggestions it offers.