We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Industrial Automation

Industrial Automation is the use of technology and machinery to automate the production, testing, and assembly of products. Such technology can save businesses time, money, energy, and resources, as well as provide greater accuracy, sustainability, safety, and precision in the production process when compared with manual production. Industrial automation can be used for a wide range of applications, from simple tasks like assembly line production, to more complex tasks like robotic surgery.

A major advantage of industrial automation is the ability to tailor processes to meet exact production requirements. Automated industrial systems can be monitored in real-time, allowing operators to make adjustments quickly, when necessary. Industrial automation typically increases the throughput as well – many more products can be made in the same period of time if done through automated processes versus manually.

Another very important feature of industrial automation is safety. Processes that require lifting a large amount of weight, repetitive motions, extreme temperatures, cutting/slicing, etc., can be done at a safe distance from human interaction. Even with humans at the controls, automated processes create distance from potential dangers, and industrial automation is responsible for decreasing the number of factory accidents causing harm to humans, including death. Automation is less burdensome to the human body too, especially with regard to repetitive motion and lifting.

Since 1966, Anaheim Automation, Inc. has served as a leading manufacturer and distributor in the motion control industry, providing high-quality products and solutions for use in industrial automation applications. Common applications include robotic process automation, packaging, machine tool, machine vision inspection systems, warehouse picking and load systems, conveyors, remote monitoring and control, and preventative maintenance. Robotic process automation reduces the need for manual labor, while machine vision can help with quality control and inspection. Remote monitoring and control can help users detect and solve system issues quickly, and preventative maintenance can help reduce downtime and maximize productivity. There are numerous ways industrial automation can improve manufacturing operations, making it an invaluable resource in modern industrial environments.

Our experienced engineers work with our industrial automation customers to find solutions for their requirements.

Industrial automation applications rely on the use of various components to ensure efficient and effective operations. Commonly used products include brushless motors and controllers, servo motors and drives, stepper motors and drivers, linear guides, gearboxes, linear actuators, X-Y-Z tables, HMIs and PLCs, and VFDs. Anaheim Automation components are designed to be durable, reliable, and cost-effective. OEM and low-volume users alike benefit from Anaheim Automation's cost-effective designs and quantity discounts.

Products for Industrial Automation

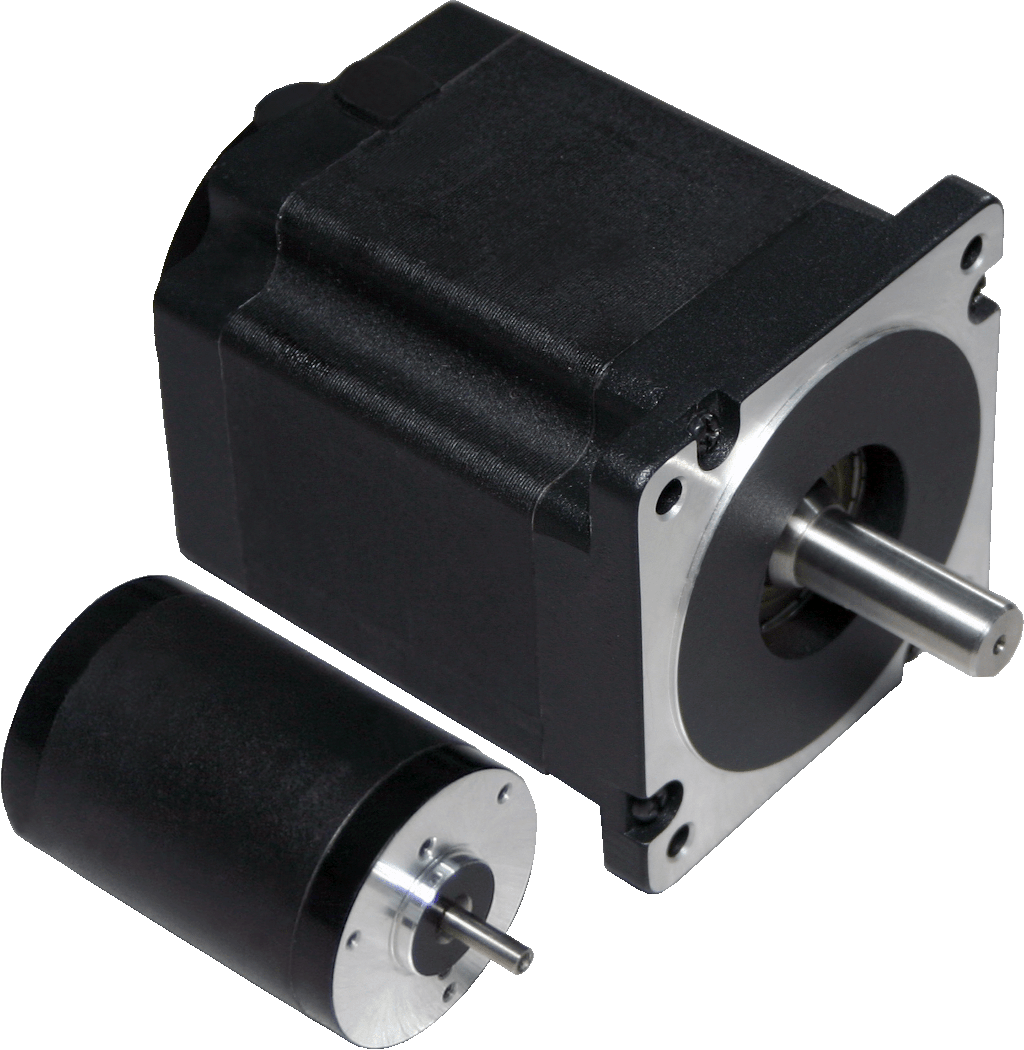

Brushless DC

Brushless DC Motors and BLDC Controllers are widely used in industrial automation applications. BLDC motors are powered by direct current (DC) and are designed to produce higher power density (compared with brushed DC motors). Brushless motors also do not require as much maintenance as their brushed counterparts, because there are no internal brushes that will wear out and need to be replaced. BLDC systems also do not require mechanical contact between the motor and the controller, which can generate friction and cause wear and tear. Brushless DC motor controls also allow for greater control over the speed and torque of the motor. This makes them ideal for applications that require precise control, such as factory automation, robotics, and more. Some of our most popular models include the BLWS, BLWR, BLY series motors and the MDC series speed controllers.

Brushless DC controllers are the brains that control BLDC motors. They are programmed to regulate the speed, torque, and direction of the motor, as well as any other parameters such as acceleration/deceleration. BLDC controllers are also capable of sensing failure in the motor, which helps to protect the motor from damage and ensures that the system is operating properly. Anaheim Automation carries a wide selection of both enclosed open-frame and PCB mountable brushless controllers, ranging from 6 to 50VDC or 85 to 265VAC input voltages. Anaheim Automation provides brushless speed controllers that are compatible with our BLDC motors, as well as other BLDC motor manufacturers. Our application engineers can assist customers in selecting BLDC motors and controllers that are the most cost-effective solution for a customer's exact requirements.

Custom motors and controllers are also available upon request, including motor shaft modifications, footprint matching, private-labeling, and more. A MOQ (Minimum Order Quantity) may be required.

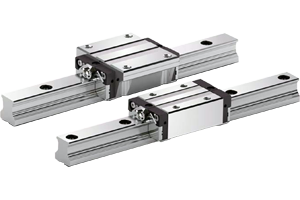

Linear Guides

Linear Guide assemblies (also known as rails and blocks) are essential for providing smooth, precise, and repeatable linear motion, and are used in various industrial automation applications such as robotics, assembly lines, conveyor systems, CNC machinery, pick-and-place equipment, and more. They are frequently used in industrial automation applications to improve precision, reduce downtime, and improve accuracy. Linear guides consist of a stationary rail that is machined to have a flat, straight surface, and a carriage (or "block") that is connected to the machine and slides along the rail. The carriage contains rollers or ball bearings that help reduce friction and ensure smooth motion.

Our high-performance Linear Guides are available in a wide range of rail widths (3mm – 63mm) and lengths (up to 4000mm, model dependent). Customers can choose between standard width and wide bearing blocks, as well as multiple block lengths (model dependent). Rails are offered with either standard or reinforced end-seals, and standard, light, or medium preload classes. Rails can be cut to a variety of requested lengths to suit application requirements.

VFD (Variable Frequency Drives)

Variable Frequency Drives, or VFDs, are adjustable speed drives used to control the speed of an AC motor, allowing the speed to be adjusted in accordance with the motor's load. This increases energy efficiency, as the motor is not drawing more energy than necessary to run at a given speed, potentially lowering operating costs and extending the lifetime of the system.

They can also reduce noise and vibration, as well as protect against overload/overvoltage. Variable frequency drives are frequently used in pump and fan applications, machine tools, conveyor and material handling, and even in HVAC systems. They are ideal for controlling the flow of water, oil, or gas, such as in compressors. Anaheim Automation carries 120V and 220V VFDs, available in either single-phase or three-phase (model dependent), and capable of handling light, normal, and heavy-duty applications.

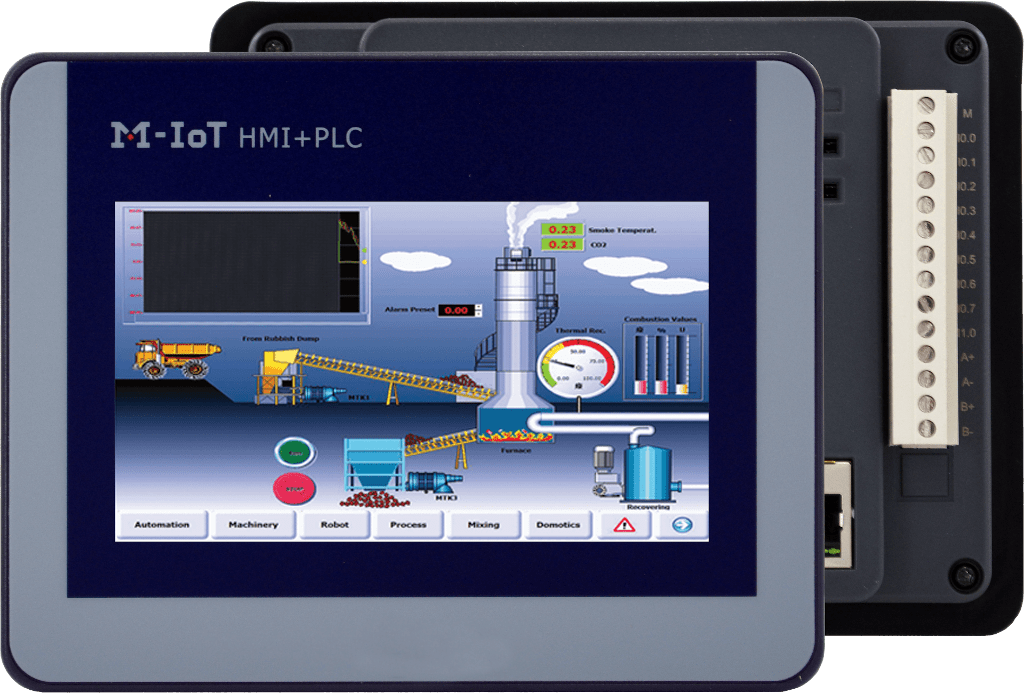

HMI (Human Machine Interfaces) and PLC (Programmable Logic Controllers)

Both Human Machine Interfaces (HMIs) and Programmable Logic Controllers (PLCs) play an important role in the automation industry. HMIs provide the interface between the user and the system, allowing the user to control machine operations and monitor the machine's performance. HMIs are typically used for data input, observation of diagnostics, and alarm monitoring. PLCs, on the other hand, are programmable devices that enable machines to run automatically and autonomously. PLCs can be programmed to run a variety of operations, from basic sequencing to complex operations involving multiple machines. PLCs are often used for controlling robotics in factories and automated assembly lines.

Anaheim Automation carries a broad line of powerful HMIs with display sizes from 4.3" to 15". Best-selling models include the economical 4.3" KNC-HMI-GL043, the 7" KNC-HMI-GL070E, and the 10.1" KNC-HMI-GL100E. HMIs are available with standard manufacturer labels, or without any labeling as "blank" units.

Our PLCs are capable of handling up to 136 I/O points and are available with a variety of features, such as high-speed counters, multiple communication ports, and additional expansion modules.

For added utility and convenience, we also offer two integrated HMI/PLC models: the 4.3" KNC-HMI-MK043E-20DT and the 7" KNC-HMI-MK070E-33DT. These combo units cut down on cost, development time, and space and include all of the standard features of our HMIs combined with the special I/O and programming functions of a PLC in one streamlined package.

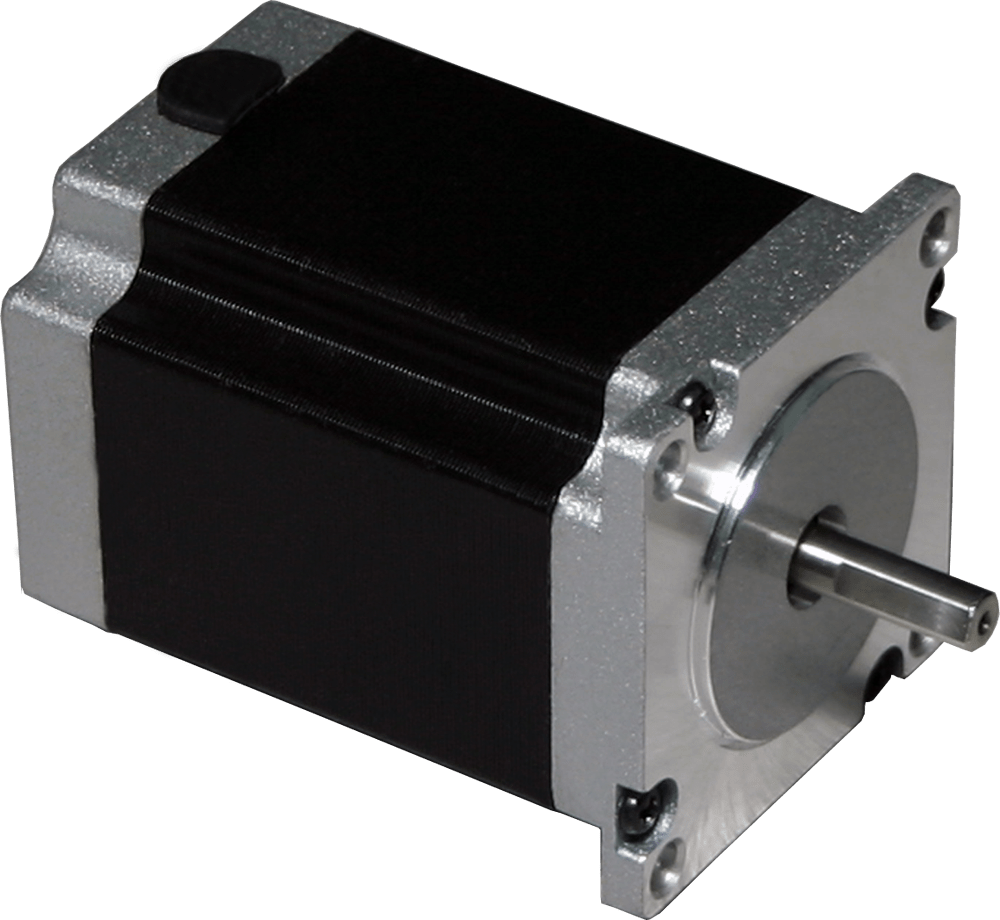

Stepper

Stepper Motors are able to precisely control the position, speed, and direction of a load, and Stepper Drivers direct the motor's speed, torque, and direction. In industrial automation, stepper products control the positioning of actuators, valves, and other mechanical components. By utilizing stepper motors and drivers, manufacturers can achieve a high degree of efficiency in their automated processes. Additionally, these products are relatively low-maintenance and cost-effective, making them an ideal option for industrial automation applications.

Anaheim Automation offers stepper motors in NEMA sizes 08 – 42, with NEMA 23, 24, 34, and 42 being the most popular for industrial applications. Standard off-the-shelf stepper motors and drivers are available in a wide range of torque ratings and voltages, with a variety of features to choose from. Stepper Motors with Integrated Drivers and Stepper Motors with Integrated Drivers and Controllers remove the need to match a motor and driver, making the R&D process fast and simple. Integrated stepper motors are available in NEMA 17 and NEMA 23 frame sizes.

Stepper Gearmotors are also often used in industrial automation applications similar to those that utilize standard stepper motors. Anaheim Automation offers a broad line of stepper gearmotors, including Stepper Motors with Planetary Gearboxes, Stepper Motors with Spur Gearboxes, and Permanent Magnet (PM) Stepper Motors with Spur Gearboxes. These gearmotors are available in multiple frame sizes, gear ratios, and torque ratings to suit any application. Our economical line of stepper gearmotors provides power and precision in one streamlined.

In addition to our standard product offering, we are also able customize our stepper motors to customer specifications. Simple additions, such as an encoder, cable, or connector, can typically be completed in 2-3 business days. Further customization, such as shaft modifications, special motor windings, private-labeling, and more are also available, but may require a Minimum Order Quantity (MOQ).

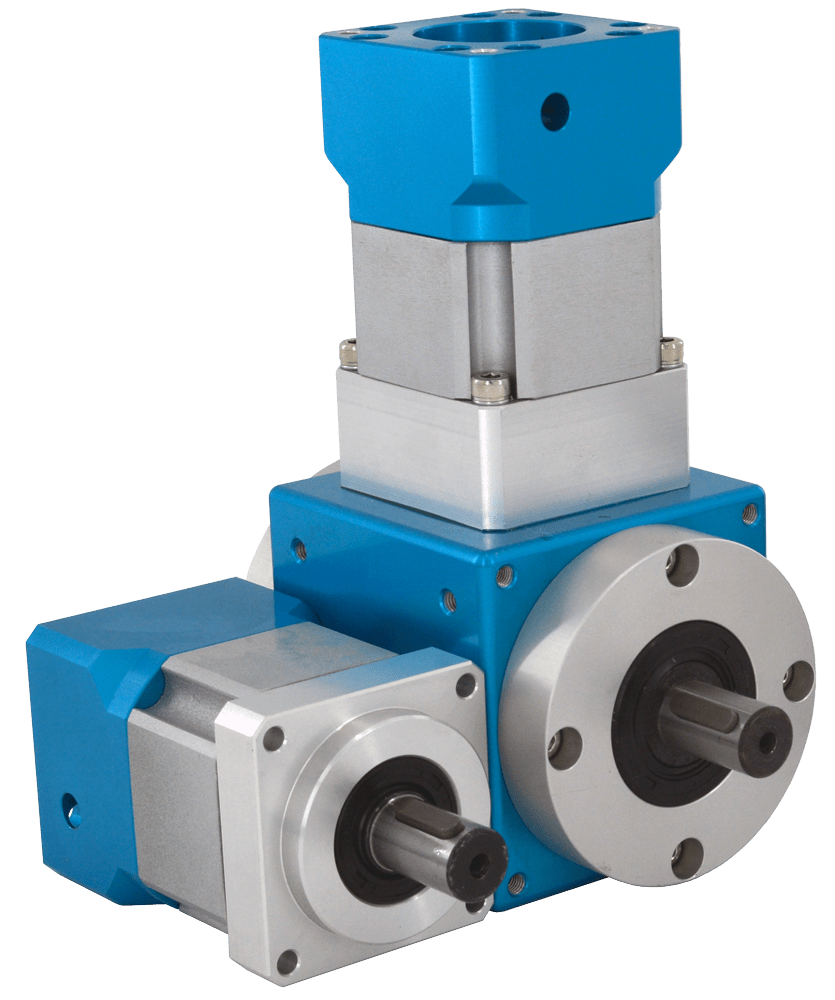

Planetary Gearboxes

Planetary Gearboxes are frequently used in industrial automation equipment, providing a powerful, efficient, and reliable method of transmitting mechanical power and increasing output torque. These gearboxes consist of multiple "planet" gears which rotate via interlocking teeth around a central "sun" gear.

This type of gearbox is ideal for a wide range of applications, particularly in the field of industrial automation, from robotics and machine tools to conveyor systems and industrial pumps. They are highly versatile, available in a variety of gear ratios, and with the ability to accommodate a wide range of motor speeds. Their compact size and robust design make them an ideal choice for use in many industrial applications. Anaheim Automation planetary gearboxes have an estimated lifetime of 20,000 operation hours.

Our standard gearboxes can be mounted to any compatible Anaheim Automation stepper, servo, or brushless motor, but can also be customized to mount to specific motor dimensions. Additional customization such as shaft modifications and private-labeling, are also available upon request, but a Minimum Order Quantity (MOQ) may be required.

Servo Motors and Drives

Servo Motors and Servo Drives are robust and powerful, making them excellent options for use in applications that require a significant amount of power and torque. In industrial automation applications, they can be used to control the movement of multiple processes at once, and are often utilized in assembly lines where they provide the motion for conveyors, robotic arms, extruders, and many other processes.

Anaheim Automation's wide selection of servo products includes motors and drives sold separately, or as 120VAC or 240VAC Packaged Servo Systems which include a motor, drive, encoder, optional brake, and all of the necessary cables for hookup. Also available are Servo Motors with Integrated Drives, which ensure a proper match and eliminate the need for external hookups.

Common Applications

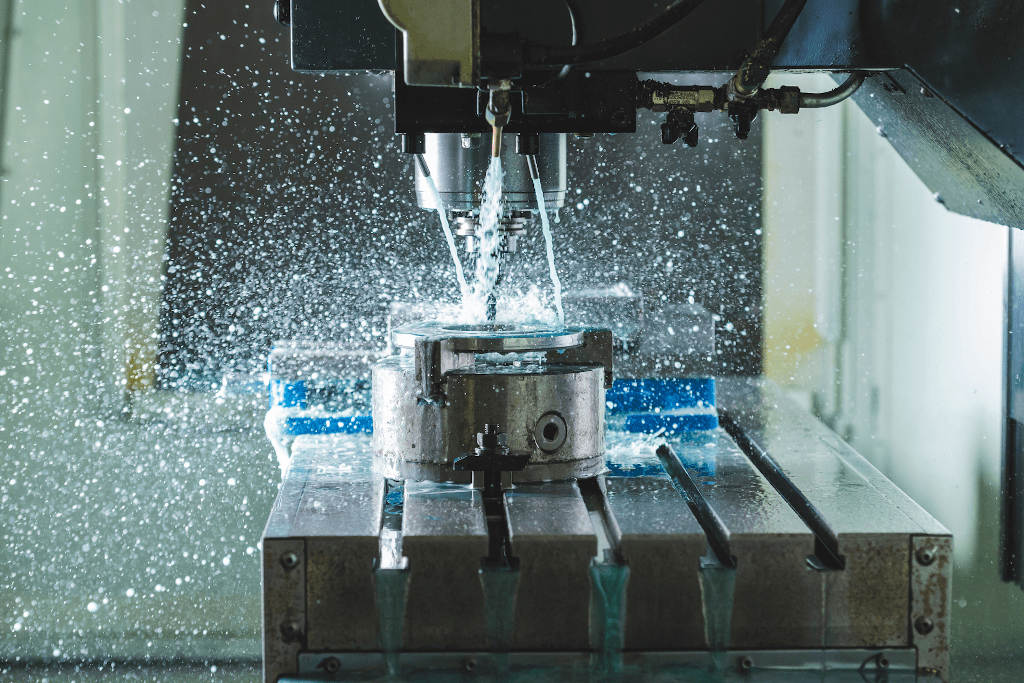

CNC Machines

CNC Machines – CNC machines are computer-numeric-controlled machines that can be used to produce accurate and precise parts which are used in industrial automation applications. They can produce components using a variety of materials, including plastics, metals, and composites. CNC machines can cut, shape, drill, and mill these materials in a variety of ways. CNCs can also be programmed to switch tools quickly and accurately, allowing them to change between cutting, drilling, etc. as needed.

Products for CNC Machinery

Linear Guides

Linear guides are used in CNC machines to provide precise positioning. Linear guides provide smooth, quiet, low-friction movement, allowing the machine to complete complex tasks with accuracy and repeatability. Often they are used in CNC equipment to move the machining tool along a straight path. They also provide support to the machine's spindle, which is responsible for rotating the machining tool.

HMIs and PLCs

HMIs and PLCs are two important components of CNC machines. HMIs provide a graphical user interface, allowing operators to easily interact with the machine, access system data (such as current machine status, alarm messages, etc.), and issue system commands. PLCs are used to control the machine's operation. They are responsible for the actual control of the machine, controlling movement and monitoring any sensors or other input/output devices.

Stepper Motors and Controllers

Stepper motors and controllers are commonly used in CNC mills and lathes, as well as in 3D printing. Steppers provide better control and performance than a BLDC motor of comparable size.

Conveyor Systems

Conveyor Systems – Conveyor systems are an integral part of industrial automation, as they are used to move materials from one point to another quickly and efficiently. Conveyors can be used in a variety of applications, from sorting and transporting materials to assembly and packaging. They are used in factories, warehouses, and manufacturing plants to increase productivity and reduce costs. Conveyors are also used in robotics and material handling to move parts and components from one station to another.

Products for Conveyor Systems

VFDs

VFDs are used to control the speed and torque of conveyor belts, allowing operators to increase or decrease the speed, as well as vary the torque on the conveyor belt, as required by the application. This helps to reduce potential errors and improve system efficiency.

Brushless DC Motors and Controllers

BLDC motors are more efficient and produce less noise than brushed DC designs. They are able to control the speed and direction of the conveyor belt, allowing operators to control the rate of production and modify the speed of the conveyor belt as needed. They can also be used with VFDs for precise control.

Planetary Gearboxes

Planetary gearboxes are well-suited to conveyor applications that transport heavy loads at low speeds due to the increased torque they provide. They are extremely robust and reliable, able to withstand the vibrations of the conveyor belt.

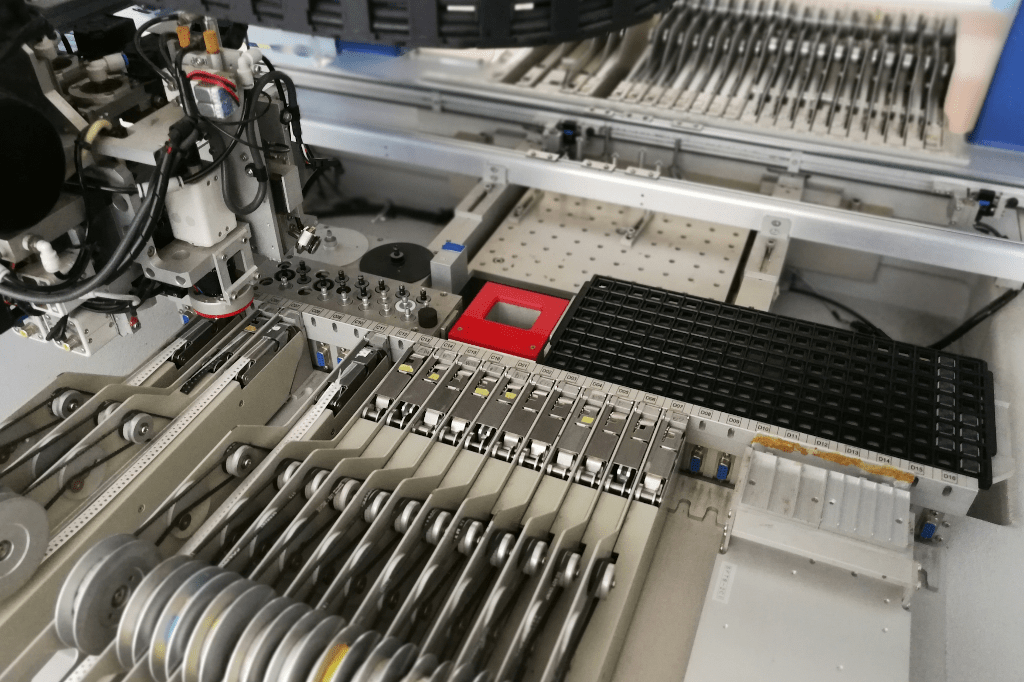

Pick-and-Place Systems

Pick-and-Place Systems – Pick-and-place systems are used in many industries, including manufacturing and warehousing, to automate the process of picking up, positioning, and placing items in a specified way. These systems are typically composed of a robotic arm, sensors, and a control system. The robotic arm is programmed to move objects from one location to another, and the sensors are used to detect the position of the objects. The control system processes the signals from the sensors and directs the movement of the robotic arm. Pick-and-place systems increase throughput and decrease errors, reducing production time and labor. These systems are capable of high levels of flexibility and can be easily adapted to handle many different types of items.

Products for Pick-and-Place Systems

Servos

Servo motors and drives provide precise motion control, moving the pick-and-place arm in programmed paths and allowing the arm to pick up and place items accurately and rapidly. Servos also help ensure repeatability, guaranteeing that the item is always moved and positioned in the exact same way.

Linear Components

Linear guides provide the necessary physical support structure for components to move in an X-Y or X-Y-Z linear direction, while ball screws transfer rotational motion into linear motion, allowing for precise control and movement of components.