We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Human Machine Interface Guide

Table of Contents

What is an HMI?

"HMI" stands for Human Machine Interface. These devices are also known as Man Machine Interface (MMI), Operator Interface Terminal (OIT), Local Operator Interface (LOI), Operator Terminal (OT), but for the purposes of this guide we will refer to them as HMIs.

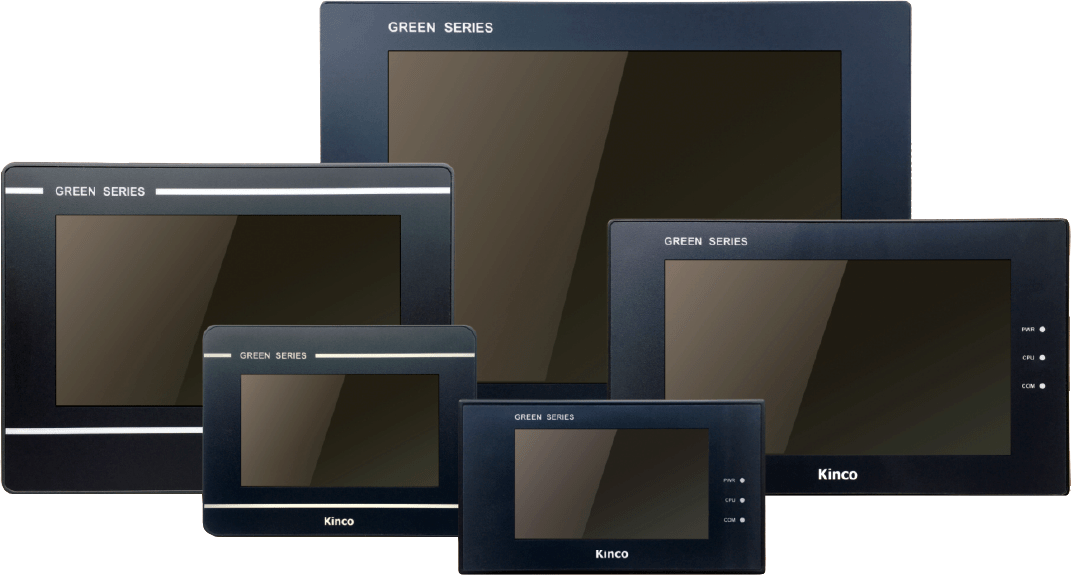

Kinco HMIs

An HMI is exactly what the name implies: a graphical interface that allows human users to interact with a system's machinery. As technology develops, HMIs are becoming more abundant in everyday tasks for consumers. Gas station pumps, self-service kiosks, ATM machines, and self checkout lines all use HMIs to process user inputs, convert them to machine readable code, and perform tasks without the need for an attendant, teller, or other employee. In the context of manufacturing and process control systems, an HMI provides a visual representation of the control system, and provides real time data acquisition. An HMI can increase productivity by providing a centralized display of the control process that is extremely user-friendly.

In manufacturing lines, HMIs have can monitor and control processes outside of a Central Processing Unit (CPU), and may be equipped with data recipes, event logging, video feed, and event triggering, so that users can update system processes without changing any of the hardware. For a manufacturing line to be integrated with an HMI, it must first be working with a Programmable Logic Controller (PLC) which acts as the CPU. The PLC takes the information from inputs (physical sensors or commands from the HMI) and transforms it to processes for manufacturing. While these inputs and processes are being performed, the HMI provides a display of received inputs, control process outputs, and defined user variables being leveraged to perform the tasks.

How Does an HMI Work?

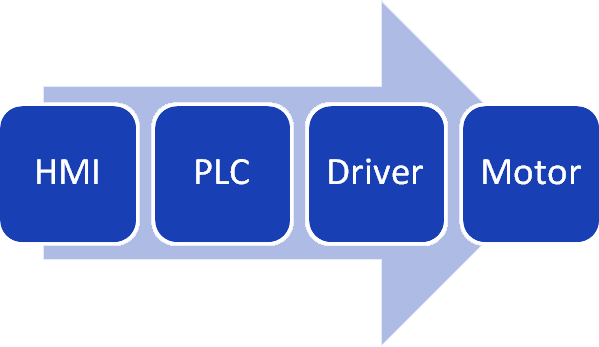

HMI System Diagram

HMIs are typically used in conjunction with a PLC (Programmable Logic Controller) to monitor and control processes in an automated system. In general terms, the HMI allows the user to communicate with the PLC via a graphical interface (typically a touchscreen). This interface allows commands to be given, and also receives and translates feedback data from the PLC, which is then presented in an easily accessible visualization on the screen. This provides the operator with much-needed flexibility and control over a given system. An excellent example of a common HMI would be a tablet or smartphone, which have built-in touchscreens that allow users to interact directly with the machine's programming.

History of the HMI

HMI products were originally designed to meet the need for easily operational machinery, while producing optimal outputs. Predecessors of the HMI include the Batch Interface (1945-1968), Command-Line User Interface (1969-Present), and the Graphical User Interface (1981-Present).

Punch-cards perforated with prearranged code are inserted into the batch machine and calculated.

The Batch Interface was a non-interactive user interface, where the user specified the details to the batch process in advance, and received the output when all the processing was done. This batch process did not allow for additional input once the process has begun, making them much less agile than HMIs used in modern manufacturing lines.

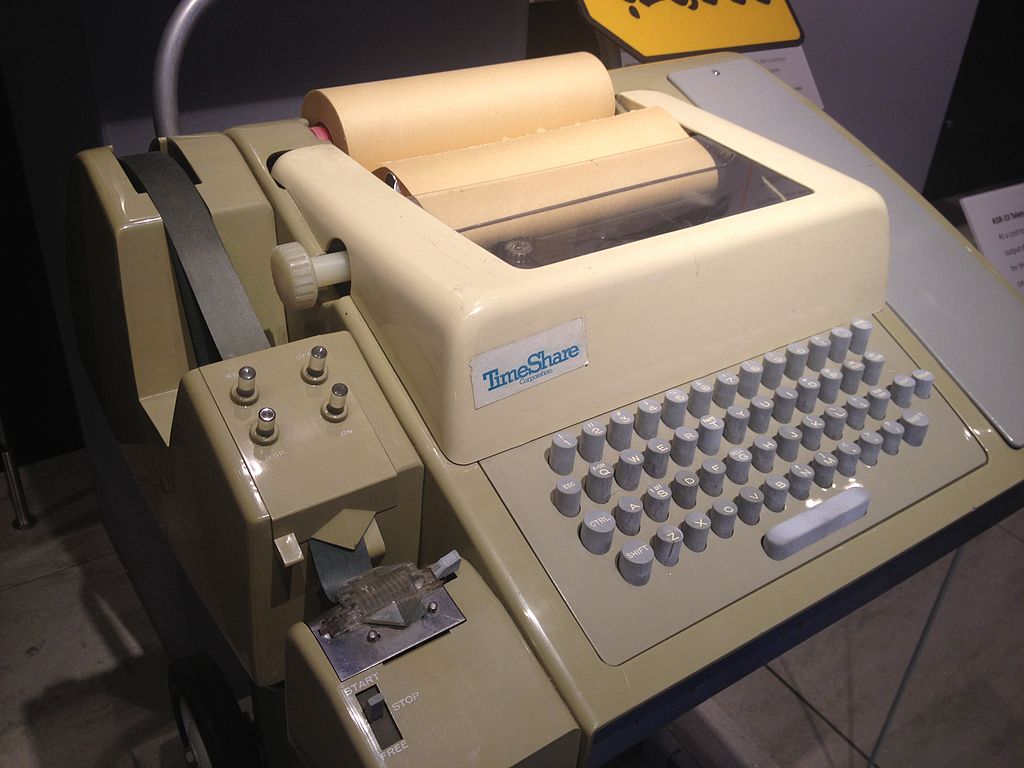

DEC VT 100 Terminal and Teletype Model 33 ASR

The Command-Line Interface was a mechanism that interacted with a computer operating system or software by typing commands to perform specific tasks. The concept of the Command-Line interface originated when teletypewriter machines were connected to computers in the 1950s, and offered results on demand; this feature was ultimately the downfall of Batch Interface, which was unable to deliver results on demand. A basic example of Command-Line Interface would be windows Disk Operating System "DOS" which dominated the 1980's.

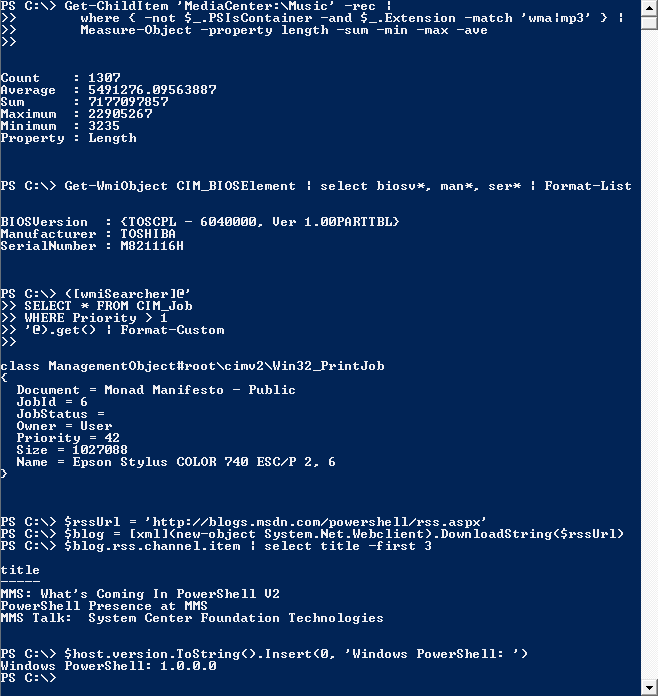

Windows PowerShell 1.0 on Vista

Over time, interfaces became increasingly complex and easier to use. One such interface would be the Graphical User Interface (GUI), which allows people to interact with programs in a more visual manner, such as via symbols on touch screens rather than text commands.

Kinco Green Series

The modern HMI stems directly from the Graphical User Interface, and comes from the need to control and operate machinery much more effectively. Human Machine Interfaces, formerly known as Man Machine Interfaces, are now leading the way in the control of manufacturing processes as extremely user-friendly devices.

Advantages of an HMI

The greatest advantage of an HMI is the user-friendliness of the graphical interface. The graphical interface contains color coding that allows for easy identification (for example: red for trouble), as well as pictures and icons which allow for fast recognition, easing the problems of language barriers.

Because HMIs increase system efficiency, they can reduce production costs, which could potentially increase profit margins. Modern HMI devices are extremely innovative, capable of higher capacity and more interactive, elaborate functions than ever before. Some technological advantages the HMI offers include converting hardware to software, eliminating the need for mouse and keyboard, and allowing kinesthetic computer/human interaction.

-

Advantages of an HMI over a PLC alone

A PLC on its own cannot provide any real-time feedback, and cannot set off alarms nor modify the system without reprogramming the PLC. The key advantage to an HMI is its functionality; an HMI can be used for simple tasks such as a coffee brewing controller, or as the sophisticated control unit of a nuclear plant. With new HMI designs emerging in the field, we are now seeing HMIs that offer remote access, allowing operators access to the terminal from a distance. Another advantage of an HMI is its customizability. The user can personalize the user interface for maximum ease-of-use.

-

Convenience

The convenience that comes with an HMI is invaluable, and the functionality achieved by digitizing a system with anHMI is unbeatable. An HMI combines all of the control features typically found throughout the automation line and placesthem in one centralized, remotely accessible location, eliminating the need, for example, to run to a red pushbutton tostop the production line in case of an emergency. With remote access, the operator does not need to be near the automationline to start, stop, or monitor production. The operator can access all the same controls on a centralized unit in acompact form. Simplicity is also a big factor in the usability of an HMI. The screens and functions provide for ease-of-useto supervise the automation line.

-

Interface Flexibility

One of the most valuable features of an HMI is the ability to personalize the interface. An HMI can fully supportthe most complex applications, with multiple screens and several routines running. If the user is looking to programan HMI with something more simplistic, they may write instructions for the controller directly into the HMI. Every HMIcomes with different features: some may play sound or video, while others offer remote access control. The design ofthe user interface should be optimized for specific applications, taking into consideration all the capabilities of thetypical user, as well as the environmental aspects such as noise, lighting, dust, vision and technological curves.

Basic Types of HMIs

There are three basic types of HMIs: the pushbutton replacer, the data handler, and the overseer.

There are three basic types of HMIs: the pushbutton replacer, the data handler, and the overseer.

-

The Pushbutton Replacer

Before the HMI came into existence, a control might consist of hundreds of pushbuttons and LEDs performing different operations. The pushbutton replacer HMI has streamlined manufacturing processes, centralizing all the functions of each button into one location. The pushbutton replacer takes the place of LEDs, On/Off buttons, switches, or any mechanical device that performs a control function. The elimination of these mechanical devices is possible because the HMI provides a visual representation of all these devices on its LCD screen, while performing all the same functions.

-

The Data Handler

The data handler is perfect for applications requiring constant feedback from the system, or printouts of the production reports. With the data handler, you must ensure the HMI screen is big enough to display information such as graphs, visual representations of data, and production summaries. The data handler includes such functions as recipes, data trending, data logging and alarm handling/logging. The data handler is used for applications that require constant feedback and monitoring. Often these data handlers come equipped with large capacity memories.

-

The Overseer

Anytime an application involves SCADA or MES, an overseer HMI is extremely beneficial. The overseer HMI will most likely require Windows to operate, and have several Ethernet ports. The overseer works with SCADA and MES. These are centralized systems that monitor and control entire sites or complexes of large systems spread out over large areas. An HMI is usually linked to the SCADA system's databases and software programs, to provide trending, diagnostic data, and management information.

Properties of an HMI

All HMIs have a processor, and memory. It is important to make sure that the processor and memory capabilities are sufficient enough to control a given system.

Additional physical properties of an HMI vary from model to model, application to application, and among manufacturers. An HMI that is located in a water plant might have various water seals around its perimeter, as opposed to an HMI that is located in a pharmaceutical warehouse which would not require waterproofing.

The size of an HMI is also a key physical property that will vary, because not all applications require a large, high-resolution monitor. Some applications may only require a small, black and white touch screen monitor. When it comes to selecting an HMI, the physical properties are extremely important because one must take into consideration the operating environment, and what safety measures the HMI needs to protect itself. Also, a specific size may be needed due to space limitations.

How to Select an HMI

An HMI is a substantial purchase, so it is important to know exactly what is required of it. HMIs typically perform one of three primary roles: a pushbutton replacer, a data handler, or an overseer. The pushbutton replacer HMI takes the place of LEDs, On/Off buttons, switches, or any mechanical device that performs a control function. The Data Handler is used for applications that require constant feedback and monitoring. Often, these data handlers come equipped with large capacity memories. The overseer works with SCADA and MES, centralized systems that monitor and control entire sites or complexes of large systems spread out over large areas. An overseer HMI is usually linked to the SCADA system's databases and software programs, to provide trending, diagnostic data, and management information.

First consider the other components that are necessary to make a manufacturing control system operate. The production line consists of all the machinery that performs the work required in the production of the product. Next, consider the various input/output sensors that monitor temperature, speed, pressure, weight and feed rate. Third, decide on the programmable logic controller (PLC) that will receive the data from the input/output sensors, and converts the data into logical combinations.

Select an HMI based on the needs of the system. HMIs are initially separated by their display size; typically spanning from 4.3” up to 15” diagonal. Within these sizes, HMIs are separated by their characteristics, namely their communication capabilities. HMIs with multiple COM and/or Ethernet ports will usually be more costly, but will allow for an overseer type application to be well connected to multiple PLCs. Make sure that the communication protocol your PLC uses can connect to the HMI by first verifying the protocol of the PLC and ensuring it exists on the HMI Communications and Connections Guide.

If you have a system that has many very simple and repeatable processes, you may not need an HMI with a large memory capacity. In this instance, you can choose an HMI based on size and choose one with the appropriate price point.

Environmental Considerations for an HMI

The operating environment is an important consideration when selecting an HMI. These might include clean-room safety, water-resistance, and more. For instance, HMIs in a warehouse application where there may be excessive noise or vibration, one might decide on a heavy-duty HMI with seals to protect against the ingress of dust, oils, and other particles. If the HMI will be used in the food processing industry, or in other applications that might require the unit to be washed down, a water-resistant or splash-proof HMI would be an outstanding choice. One must also consider temperature as a factor in the selection process. If used in a steel plant, next to a furnace, users should select a unit which can withstand extreme temperatures.

Which HMI Programming Software to Choose?

HMIs generally have their own software through which they are programmed. When selecting an HMI to embed into your system, be sure that the available communication protocol drivers exist in that HMI Software. If they do not, you will not be able to connect the HMI with your CPU, and no data will be transmitted to display.

Wiring an HMI

Wiring an HMI into a system may be an easy task if a PLC is already integrated. This connection is as simple as connecting a USB/RS-232/RS-485 cable between the HMI and PLC. In some instances, both units are equipped with wireless features, making the connection even easier. Although the wiring between the PLC and HMI may be an easy task, the wiring between the PLC and the actual automation line could prove more difficult. Depending on the size and complexity of the application, PROFIBUS extensions may be required for the PLC. A PROFIBUS extension is similar to a power strip that extends one input/output to multiple input/outputs by connecting to the expansion port of the PLC. A wiring schematic from the production line to the PLC is highly recommended, making programming the HMI significantly faster. For further information on wiring specific models, please refer to the spec sheet for that item. For more helpful information, users can view our instructional videos in the Video Tutorial section of our website.

HMI and PLC

How can a PLC be controlled without ladder logic? How does an HMI replace the standard software a PLC comes with? Ladder logic is simply conditional programming. For example, if input 1 is energized, then coil 1 will be powered. A statement has to be true for the output to be executed. The same can be achieved with C programming. However, in order to program an HMI to operate a PLC properly, all the registers of the PLC must be known. A good way to learn how to program a PLC via an HMI is to first start working with the PLC and the software it came with. This helps build an understanding of how to operate the PLC without the HMI. That knowledge will easily transfer over when the user is ready to connect the two units together.

HMI/PLC Combo Units

HMI/PLC combination units are HMIs with an integrated PLC, which removes the need for wiring any communications to these units and makes the installation process faster and easier than separate HMI/PLC units. We offer these HMI/PLC combos in a 4.3" model (KNC-HMI-HP043-20DT) and a 7" model (KNC-HMI-HP070-33DT).

HMI Applications

HMIs are used throughout various industries including manufacturing plants, vending machines, food and beverage, pharmaceuticals, and utilities, among many other applications. HMIs, along with PLCs, are typically the backbone of the production line in these industries. The integration of the HMI into any manufacturing system can vastly improve operations. The HMI allows for supervisory control and data acquisition in the entire system, so parameter changes are available at the operator's choosing.

For example

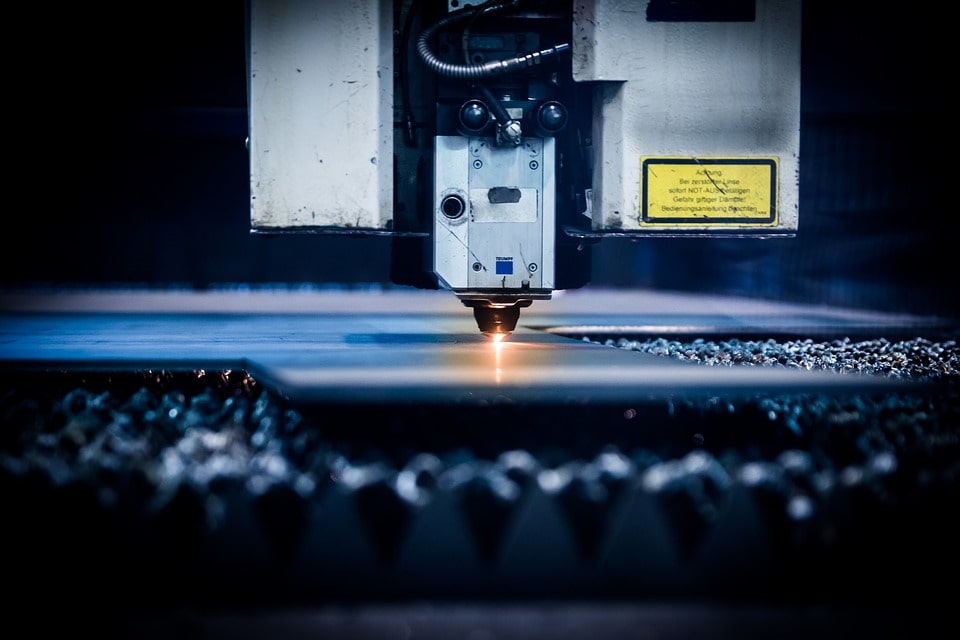

In metals manufacturing, an HMI may allow easy control over how the metal is cut and folded, and the speed at which it is done.

HMIs are used in bottling processes to control all aspects of the manufacturing line, such as speed, efficiency, error detection, and error correction.

An HMI also offers improved stock control and replenishment, meaning fewer replenishment orders are required of the vendors. Utility companies may use HMIs to monitor water distribution and waste water treatment.

HMI Troubleshooting

If you are experiencing issues with your HMI, we offer several instructional videos which may offer assistance. Please refer to the Video Tutorials section of our website. For further assistance, please contact our applications engineers.

HMI Glossary

Batch interface – user interface which receives a "batch" of data and commands from the user in advance, and then outputs the calculations when all the processing is done.

CANopen – a communication protocol based on the frame-based CAN (Control Area Network) Protocol.

Command-Line Interface – an interface which communicated on-demand with a computer operating system or software via typed commands.

GUI – Graphical User Interface; precursor to the HMI; interface allowing a user to communicate on-demand with a system via graphical icons, audio indicators, and more.

HMI – Human Machine Interface; an interactive interface allowing a user to communicate commands to and receive feedback data from a system; capable of on-demand graphical and text-based communication, among others.

LB – a local bit register is just a 1-bit register which has been declared within the scope of the program.

LW – a local word register is a 32-bit register which has been declared within the scope of the program.

Macro – macro instructions are an advanced touch screen control method. Macro strengthens the functions of the touch screen, so it has the same logic and arithmetic operations as the PLC. The use of macros will enable the touch screen to implement many powerful functions that cannot be supported by regular components, perfecting the human-machine interface.

Recipe – a recipe activates data transmission of consecutive registers, and supports downloading data from the memory of the recipe card to the PLC, and vice versa.

RW – a recipe word register is a 32-bit register that will execute sequentially when activated.

TFT – a thin film transistor is an LCD that uses thin film transistors technology to improve image quality.