We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Brush DC Motor Guide

Table of Contents

What is a Brush DC Motor?

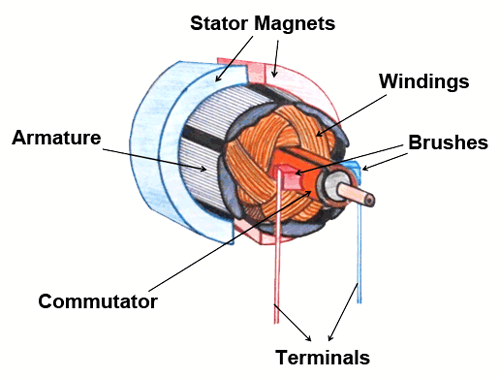

A Brush DC Motor is an electric motor run from a direct current power source, using carbon brushes for internal commutation. Brush DC motors provide precision speed control, and are noted for a particularly high torque-to-inertia ratio, having the potential to supply three to four times more torque than its rated torque. If needed, brush DC motors can provide up to five times more torque without stalling. One of the earliest commercially-used motors, the Brush DC Motor is still commonly used in a variety of applications because of its ability to vary the speed-torque ratio in almost any way.

Image Source: electrical4u.com

Internally, Brush DC Motors consist of the following components: the axle, armature/rotor, rotor windings, commutator, stator, magnets, and brushes. The brushes are affixed to two terminals, which extend out of the motor body's end cap (opposite the motor shaft), to be connected to an external DC power source.

Brush DC Motor Basics

Brush DC Motor operation is based on electromagnetism. When voltage is applied across the two terminals, a proportional speed is outputted to the shaft of the motor. The motor consists of a stator (which includes the housing, permanent magnets, and brushes), and a rotor (which consists of the output shaft/axle, windings, and commutator). The stator is stationary, while the rotor rotates with respect to the stator.

The design of the Brush DC Motor is quite simple, in that a permanent magnetic field is created in the stator by either of two means: permanent magnets or electro-magnetic windings. If the field is created by permanent magnets, a Brush DC Motor is said to be a permanent magnet DC motor (PMDC), and if created by electromagnetic windings, this is often referred to as a shunt-wound brush DC motor (SWDC). Today, because of cost-effectiveness and reliability, the PMDC motor is the motor of choice for most applications up to about 2.0 horsepower.

Opposing the stator field is the armature field, a magnetic field generated by a changing electromagnetic flux coming from windings located on the rotor. The magnetic poles of the armature (rotor) field will attempt to line up with the opposite magnetic poles generated by the stator field (e.g. rotor South -> stator North; rotor North -> stator South), causing the rotor to rotate. Electricity is carried to the rotor windings via the commutator, which makes sliding contact with the carbon brushes located in the stator.

Carbon Brushes

A key component to the Brush DC Motor is a device known as a carbon brush, which conducts current between the DC power supply and the commutator ring, and thus the rotor windings. In other words, the brushes are critical because they conduct electrical current between stationary wires outside of the motor, and moving parts within the motor. More specifically, the brushes are connected to the stationary wires outside the motor via the conductive terminals that extend outside of the motor housing. Inside the motor, the terminals attach to the brushes, which are typically spring-loaded to ensure constant contact with the commutator ring. In this way, the brushes slide, or brush, against the commutator ring as it rotates, conducting current by way of this "sliding" contact. Brush DC Motor brushes are commonly made of graphite, which is both conductive and lubricating.

Carbon brushes are considered to be both the most critical, yet weakest point of the Brush DC Motor. They are highly susceptible to wear, especially when running the motor outside of its parameters. The wearing of carbon brushes is a disadvantage of Brush DC Motors, but fortunately, brushes are easily replaced. While many people consider carbon brushes in brush DC motors to be a "Black Art," they still serve a purpose when operated in the proper conditions.

How does a Brush DC Motor work?

Source: https://engineeringnotesonline.com/dc-motors/ by Er.Sushil Neupane

As shown in the above diagram, the stator of a brush DC motor consists of two curved permanent magnets of opposing polarity. These stator magnets are stationary relative to the motor housing. Comprising the inner armature of the motor is a metal loop, which is connected to a split ring commutator – a metal ring with gaps on opposite sides. These gaps are important because they create electrically-isolated segments within the commutator ring, and each segment connects to either side of the armature loop. This allows current to flow through the armature loop in one direction.

As stated in the previous section, the commutator ring is in constant sliding contact with a pair of carbon brushes, which are wired to an external DC power supply by way of terminals extending outside of the motor's housing. Electricity flows from the power supply through the carbon brushes, conducted into the armature loop from the commutator ring, forming a complete circuit. In the diagram above, current is shown flowing clockwise through the armature loop (see: "electron motion").

Once the armature loop is electrified, it becomes an electromagnet with its own magnetic field, the poles of which will attempt to line up with the opposite magnetic poles generated by the stator magnets. This magnetic push/pull causes the armature loop to rotate (the stator's north pole repels the armature's north pole, while the stator's south pole attracts it), and the commutator ring rotates along with the armature loop to which it is connected.

As the split ring commutator rotates, the carbon brushes make contact with alternating segments of the commutator ring, with momentum allowing the brushes to slide past the gaps in the ring until making contact with the next segment. When contact switches from one segment to the next, this causes the current flow through the armature loop to switch directions, which means its magnetic field switches polarity. This changing polarity causes the armature to once again rotate in relation to the stator magnets. As long as the electrical circuit is connected, this cycle repeats continuously, causing the motor's rotation.

With just one armature loop, the rotation speed will be irregular. It is even possible for the armature to get stuck in position, with the carbon brushes making contact with the gaps in the commutator ring (rather than with the electrically conductive commutator segments), breaking the complete electrical circuit through the armature loop. For this reason, real brushed motors typically have multiple armature loops, or rotor windings, with each loop connected to its own set of commutator segments. In this way, each armature loop/rotor winding becomes its own electrically-isolated, complete circuit, and each loop takes a turn becoming an electromagnet when in contact with the carbon brushes. Increasing the number of armature loops, or rotor windings, increases torque and thus the speed of the rotation, which makes the rotation speed smooth and continuous.

How is a Brush DC Motor Controlled?

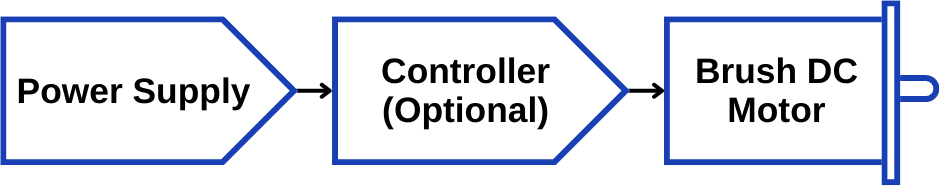

Brush DC motor speed control is simple, and does not require complicated electronics. The voltage applied to a Brush DC Motor is proportional to rotational speed. In other words, the higher the armature voltage, the faster the rotation. This relationship is linear to the Brush DC Motor's maximum speed. By applying variable supply voltage, speed control can be achieved. Changing rotational direction can be done by reversing the field or armature connections. Electronic speed controls have been developed to provide more accurate and precise operation.

Anaheim Automation Brush DC Speed Controllers

In a Brush DC Motor, torque control is also easy to accomplish. Output torque is proportional to input current. Therefore, if current is limited, you have also limited the torque which the brush motor can achieve. Happily, variable speed or variable torque electronics are easy to design and manufacture. Varying the speed of a Brush DC Motor requires little more than an appropriate potentiometer. In practice, these have been replaced for all but sub-fractional horsepower applications by the SCR and PWM drives (sometimes referred to as controls), which offer relatively precise control voltage and current.

Common controls for Brush DC Motors are available at the low-end of the product offering (up to 2 horsepower). The cost will depend on the accuracy requirement, but many brush motors can be accompanied with controllers covering a wide range of prices.

Block Diagram for Systems That Use a Brush DC Motor

56C Frame DC Motors

Brush DC Motor Types

There are five basic Brush DC Motor types:

Brushed Shunt Mount DC Motor:

A brushed shunt wound motor will run at constant speed regardless of the load.

Brushed Series Wound Motor:

Speed varies automatically with the load, increasing as the load decreases. This series wound motor is usually limited when heavy power demand is necessary.

Brushed Compound DC Motor:

A combination of the brushed shunt and brushed series wound motors, combining the helpful characteristics of both – the efficient speed regulation of a shunt motor with the high starting torque of a series wound motor. These brushed compound motors are typically used when applications require high starting torque and constant speed.

Permanent Magnet Brush Motor:

As the name implies, these contain permanent magnets, which eliminate the need for external field current. This design yields a smaller, lighter, and more energy-efficient Brush DC Motor. This is the type of Brush DC Motor Anaheim Automation carries.

Separately Excited Brush Motor:

These are used for their high torque capability at low speeds. This is achieved by separately generating a high stator field current and enough armature voltage to produce the required rotor torque current.

Where is the Brush DC Motor used?

Due to its longevity and reliability, the Brushless DC Motor has displaced the Brush DC Motor in many applications, but the Brush DC Motor is still appropriately chosen for many applications. Most commonly, the Brush DC Motor is found in household applications, but is also used in the industrial world thanks to its versatility in altering its torque to speed ratio.

Which Industries Use the Brush DC Motor?

The Brush DC Motor is a favorite in the automotive industry because of its simplicity and affordability. Many automotive manufacturers use them for power windows, seats, and more. However, the Brush DC Motor can be found in nearly every industry ranging from computers to manufacturing.

Brush DC Motor Applications

Brush DC Motors are used in a wide range of applications, from toys to Jacuzzi pumps. They are available in a variety of sizes and torque and speed specifications, so they are candidates for virtually any motion control endeavor. Aside from the automotive applications mentioned above, Brush DC Motors are also popular in steel rolling mills, paper machines, cranes, and electrical propulsion.

Brushed DC motors are available in certain standard voltages, which roughly increase in conjunction with horsepower. The smallest industrial-type brush motors are rated around 90VDC and 180VDC. Larger industrial brush motors may be rated at 250VDC or higher. Specialty Brush DC Motors for use in mobile applications are typically rated 12, 24, or 48 VDC. Other tiny brush motors can be rated as low as 5 VDC. This type of Brush DC Motor is very popular among hobbyists.

Advantages and Disadvantages of the Brush DC Motor

The DC Brush Motor is one of the earliest of all electrical motor designs. It is usually the motor of choice for the majority of torque control and variable speed applications. The following discusses the advantages and disadvantages of using a Brush DC Motor in machinery and processes.

Advantages – Brush DC Motor

- The Brush DC Motor has a simple construction, therefore may not require a controller. When a controller is chosen, it is typically a simple and inexpensive drive design.

- Easily-understood design technology facilitates in the quick application of the DC Brush Motor

Disadvantages – Brush DC Motor

- Less reliable in control at lowest speeds

- Physically larger than other motors producing equivalent torque

- More high-maintenance than brushless DC motors due to wear of the carbon brushes

- A Brush DC Motor are vulnerable to dust which decreases performance

How much do Brush DC Motors cost?

The Brush DC Motor has a relatively inexpensive start up cost and simple design. In some cases, the Brush DC Motor can cost half the price of their Brushless DC Motor counterparts. However, the brushes within the Brush DC Motor are apt to wear and require replacement, making it a higher-maintenance option, so long-term costs should be considered.

Physical Properties of a Brush DC Motor

Diagram of a Brushed DC Motor

Image Source: cecas.clemson.edu

A typical Brush DC Motor contains six components: stator, rotor/armature, commutator, brushes, an axle/shaft, and magnets. The stator surrounds the rotor, and generates a magnetic field by means of electromagnetic windings or permanent magnets. The rotor can also be called the armature. It consists of one or more windings that produce a magnetic field when energized, causing the motor to turn. The split-ring commutator is a metal sleeve with gaps 180° apart, that is located on the axis, connected to the rotor windings (armature loops). This performs mechanical commutation of the windings, eliminating the need for a controller to switch the current. Carbon brushes conduct electrical current into the rotor windings via "sliding contact" with the commutator ring. It is because of this contact that the brushes and commutator are prone to wear.

Brush DC Motor Lifetime

The life of the brushes, bearings, and gearbox (if used) all play a role in the longevity of a Brush DC Motor. Most commonly, Brush DC Motor life expectancies range from 2,000 to 5,000 hours of operation, although actual service life varies depending on usage. Brush DC Motor design, operating current, speed, voltage, and other conditions are all contributing factors.

Required Maintenance for a Brush DC Motor

Always make certain that the Brush DC Motor, as well as the motor environment, are kept clean, to prevent the motor from encountering any type corrosion or damage due to vapors, moisture, dirt, oils, or debris. Ensure all mounting bolts are fastened tightly, and the operation of the Brush DC Motor is in accordance with the given instructions on installation. Brush DC Motors tend to have increased maintenance requirements compared to other types of electric motors, because many of the motor's components are constantly interacting with one another. Over time, the brushes will wear and will require replacement. Furthermore, the interaction between the commutator and the brushes will cause debris and contaminants to settle within the Brush DC Motor, requiring additional cleaning. Most commonly, this debris will be found between the commutator and the shaft, as well as between the winding and the armature.

Environmental Considerations of a Brush DC Motor

The environment in which a Brush DC Motor will be used plays a major role in the life cycle of a Brush DC Motor and other electrical and electronic devises in the system. Dry, warm environments may increase the wear of the brushes, and quicken the breakdown of the commutator and bearings, ultimately shortening the lifetime of the motor. Running the Brush DC Motor in a cooler environment, with external cooling by forced air, may help the Brush DC Motor to perform better. However, extreme drops in temperature can potentially increase the viscosity of the Brush DC Motor lubricants, causing it to run at a higher current.

The following environmental and safety considerations must be observed during all phases of operation, service and repair of a Brush DC Motor system. Failure to comply with these precautions violates safety standards of design, manufacture and intended use of the Brush DC Motor and controller (if also used). Please note that even with a well-built Brush DC Motor, products operated and installed improperly can be hazardous. Precaution must be observed by the user with respect to the load and operating environment. The customer is ultimately responsible for the proper selection, installation, and operation of the Brush DC Motor system.

Avoid Flammable Gas, Dust, Oil, and Vapor

The atmosphere in which a Brush DC Motor is used must be conducive to good general practices of electrical/electronic equipment. Do not operate the Brush DC Motor in the presence of flammable gases, dust, oil, vapor or moisture. For outdoor use, the Brush DC Motor and controller must be protected from the elements by an adequate cover, while still providing adequate air flow and cooling. Moisture may cause an electrical shock hazard and/or induce system breakdown. Due consideration should be given to the avoidance of liquids and vapors of any kind. Contact the factory should your application require specific IP ratings. It is wise to install the Brush DC Motor and controller in an environment which is free from condensation, dust, electrical noise, vibration and shock.

Additionally, it is preferable to work with the Brush DC Motor system in a non-static, protective environment. Exposed circuitry should always be properly guarded and/or enclosed to prevent unauthorized human contact with live circuitry. No work should be performed while power is applied. Don't plug in or unplug the connectors when power is ON. Wait for at least 5 minutes before doing inspection work on the Brush DC Motor and controller system after turning power OFF, because even after the power is turned off, there will still be some electrical energy remaining in the capacitors of the internal circuit of the controller.

Important: Plan the installation of the Brush DC Motor and controller in a system design that is free from debris, such as metal debris from cutting, drilling, tapping, and welding, or any other foreign material that could come in contact with circuitry. Failure to prevent debris from entering the Brush DC Motor system can result in damage and/or shock.

Formulas for a Brush DC Motor

Calculating Motor Speed, RPM for a Brush DC Motor:

=V-(Tl/Kt+I0)/Ke×Rt ಏ 1000

Where:

V = supply voltage

Tl = load torque (oz-in.)

Kt = motor torque constant (oz-in./A)

I0 = motor no-load current (A)

Rt = motor terminal resistance (Ohms)

Ke = motor voltage constant (V/1,000 rpm)

Note: It is possible to solve for an unknown quantity (voltage or current) when speed is known.

Determining Speed and Current Flow for a Brush DC Motor:

W = (VS – I x Rmt) / KE and I = TL / KT + INL

Where:

W = Speed

VS = Supply Voltage

Rmt = Motor Terminal Resistance

I = Current

T = Load Torque

KE = Back EMF Constant

Brush DC Motor History

The history of the Brush DC Motor can be traced back to the 1830s, when Michael Faraday set to devise an experiment to demonstrate whether or not a current-carrying wire produced a circular magnetic field around it. Michael Faraday's experiment turned out to be a success; the current-carrying wire did produce a circular magnetic field.

While Michael Faraday is often credited for the invention of the electric motor, his experiment is really just a lab demonstration; it can't be harnessed for useful work. Several other scientists such as Joseph Henry and William Sturgeon based their work on Faraday's experiment and theories. By the late nineteenth century, the design of Brush DC Motor had become well-established. The demand for the Brush DC Motor has skyrocketed since then as a necessity in industrial applications.

Brush DC Gearmotors

Brush DC Gearmotors provide an affordable and simple solution for high-starting-torque and low-inertia applications. Brush DC Permanent Magnets offer lower current drain for more efficient battery operation in portable applications. When the power is removed, the Permanent Magnets provide lower shaft coast. PMDC Gearmotors can be reversed by simply changing the polarity of the line connection. Brush DC Gearmotor performance varies by the quality of its components. Some key quality factors to consider are gearing, hobbing, housings, bearings and lubrication.

Anaheim Automation offers four different types of Brush DC Gearmotors: PMDC Motors with Planetary Gearboxes, High-Torque PMDC Motors with Spur Gearboxes, Standard PMDC Motors with Spur Gearboxes, and PMDC Motors with Worm Gearboxes.

Accessories

Motor Cable with Connector and Friction Brake

In addition to Brush DC Motors, Anaheim Automation carries a line of Brush DC Drivers and Controllers, along with a comprehensive line of Brush DC Gearmotors. We also offer a broad selection of Accessories and Value-Added Services, including Encoders, Friction Brakes, Cables, and Connectors. Encoders, brakes, cables, and connectors can be assembled to your brush DC motor by Anaheim Automation, often within 2 to 3 business days. Contact Us for more information.

Troubleshooting a Brush DC Motor

Note: Exercise caution when troubleshooting your Brush DC Motor. Ensure safety guards are in place, disconnect any power, and discharge all capacitors prior to inspecting the Brush DC Motor.

Problem: After installation, Brush DC Motor does not start.

Solution: Ensure the Brush DC Motor is correctly wired, and verify the appropriate voltage is being generated from the controller. If necessary, replace the fan guard, and check to make sure the armature is not rubbing against the magnets due to misalignment. The Brush DC Motor may need to be replaced. Depending on the original cost of the motor, the replacing the brushes might make better financial sense. For Anaheim Automation Brush DC Motors, replacing the entire motor is the most cost-effective approach.

Problem: Brush DC Motor loses power while running.

Solution: Check the load being applied to the motor. Changes in load may be too much for the Brush DC Motor to handle. Measure the amp draw next to the motor's full load amp rating to be sure the Brush DC Motor is appropriately sized for the application. Check the settings on the controller and the armature as well. Torque and compensation settings may be slightly off, and the armature needs an open connection.

Problem: Brush DC Motor fails to start after having been operational.

Solution: If this is the case, the brushes may have worn down and are unable to interact with the commutator. Disassemble the motor and check both the commutator and armature for any burnt bars or a burnt coil. Finally, ensure the voltage is emitting out of the controller.

Note: disassembling an Anaheim Automation motor while it is under warranty will void the warranty. Please contact us if you need an RMA or technical assistance. Please do not send in a motor for repair or replacement without first being issued an RMA from Anaheim Automation personnel.

Problem: Brush DC Motor is not accelerating quickly enough.

Solution: Check the length of the brushes to ensure they are not worn out. Look for any defective bearings (bearings generating loud noise is a sign); replace or lubricate bearings if needed.

Problem: The Brush DC Motor is running in reverse.

Solution: Double check the wiring arrangement, you probably need to interchange the two leads.

Problem: The Brush DC Motor makes a clicking sound.

Solution: Remove burr from the armature with a commutator stone.

How to Select a Brush DC Motor

The first step in selecting the appropriate Brush DC Motor is to determine your maximum required speed. After this is determined, decide whether or not a gearbox is required. Typically a gearmotor should be used for max speeds less than 1000 RPM, and a Brush DC Motor only if max speeds exceed 1000 RPM. Next, decide what torque your application requires. When using a gearbox, be sure to select the appropriate gear ratio by dividing the maximum speed of the gearbox by the max desired output speed (See ‘Formulas for a Brush DC Motor' for more information).

After you have determined speed and torque requirements, select a frame size for your Brush DC Motor that will fit the size restraints of your application while maintaining the ability to generate the amount of torque needed. Then, select the appropriate windings that will most closely deliver the desired current draw and speed, given the load torque and supply voltage. (See ‘Formulas for a Brush DC Motor' for more information).

A general rule to keep in mind when selecting any type of Brush DC Motor is the environment in which it will be running. Be sure to consider what the Brush DC Motor will be exposed to (excessive heat, fluids, debris, etc). You may also need to consider any standards or local regulations that have been set, as well as the cost of the Brush DC Motor, and any type of special customization options that may be available from the manufacture that will better suit your application requirements. Anaheim Automation provides customization of motors and controls, however, minimum purchase requirements may apply.

Brush DC Motor FAQs

Q: What variables contribute to Brush DC Motor noise?

A: Motor mounting in application, load and speed of the motor, and type of bearings all play a role in motor noise.

Q: When do I use a Planetary Gearbox, and when do I use a Spur Gearbox?

A: For a low-current, low-noise, and high-efficiency application, a Spur Gearbox would be the better choice. Applications with higher torque requirements, higher current consumption, lower efficiency, and higher audible noise levels, one should consider a Planetary Gearbox.

Q: What is Backlash?

A: Backlash is the clearance between mating components, such as the gears within a gearbox. Theoretically, backlash should be zero, but in practice, some backlash should be allowed to prevent jamming. This is especially true in reversing mechanical designs. Generally the greater the accuracy, the smaller the backlash needed. Backlash in gearboxes is most commonly created by cutting the teeth deeper into the gears than the ideal depth. Another way of introducing backlash is by increasing the center distances between the gears.

Q: Does a Brush DC Motor need to run at the rated voltage?

A: No, however it is recommended to run the Brush DC Motor slower or at less than the nominal voltage. Brush DC Motor life can be affected by the speed of operation. Operating at a lower voltage means lower brush/commutator wear on the motor, while lower current consumption will also contribute to longer motor life.

Q: Are Anaheim Automation's Brush DC Motors reversible?

A: Yes, this can be easily done to by reversing the polarity on the Power Supply.

Q: What is the primary difference between a Brush DC Motor and a Brushless DC Motor?

A: Because of brush wear, a Brush DC Motor requires more maintenance, and has shorter life than Brushless DC Motors. Brushless DC Motors require the use of an Electrical Speed Controller, but offer higher efficiency.

Brush DC Motor Glossary

Armature – the component of the motor that produces power, located in the rotor of a Brushed DC Motor.

Brush – mechanism that conducts current in between moving parts and stationary wires.

Brushed Compound Motor – a type of brush DC motor that combines the characteristics of two other types: the brushed shunt motor and the brushed series wound motor.

Brushed Permanent Magnet Motor – contains permanent magnets inside, which eliminates the need for external field current. This design yields a smaller, lighter, and energy-efficient Brush Motor. Also called PMDC Motors.

Brushed Separately Excited Motor – used for its high torque capability at low speeds. This is achieved by separately generating a high stator field current and enough armature voltage to produce the required rotor torque current.

Brushed Series Wound Motor – speed varies automatically with the load, increasing as the load decreases.

Brushed Shunt Wound Motor – run at constant speed regardless of the load.

Commutator – mechanism which reverses the direction of current in certain electric motors. In brush DC motors, the commutator is a ring located in the rotor of the motor, around the axle/shaft, which conducts current from the carbon brushes to the rotor windings.

Direct Current – electrical charge constantly flows in the same direction. Opposite of an alternating current, where current periodically switches direction.

Electrical Power – electric circuits transferring electrical power at a given rate.

Overcurrent – can lead to damaged equipment due to excessive heat produced within a Brush DC Motor. This occurs because a larger amount of electric current is produced through the conductor.

Rotor – rotating device in an electric motor which rotates about the Brush DC Motor generating torque among the rotor's axis.

Stator – the part of the Brush DC Motor that is stationary.

Torque – the ability of a force to rotate a given object about an axis or fulcrum.

Windings – loops of copper wire wound into the rotor; when DC power is applied, each loop acts as an electromagnet whose magnetic field interacts with the stator magnets, causing the rotor to rotate.