We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Linear Guide Product Guide

Linear Guide Product Guide

Table of Contents

What Is A Linear Guide?

Linear Guides are a block and rail system that helps support the motion of an application.

How Do Linear Guides Work?

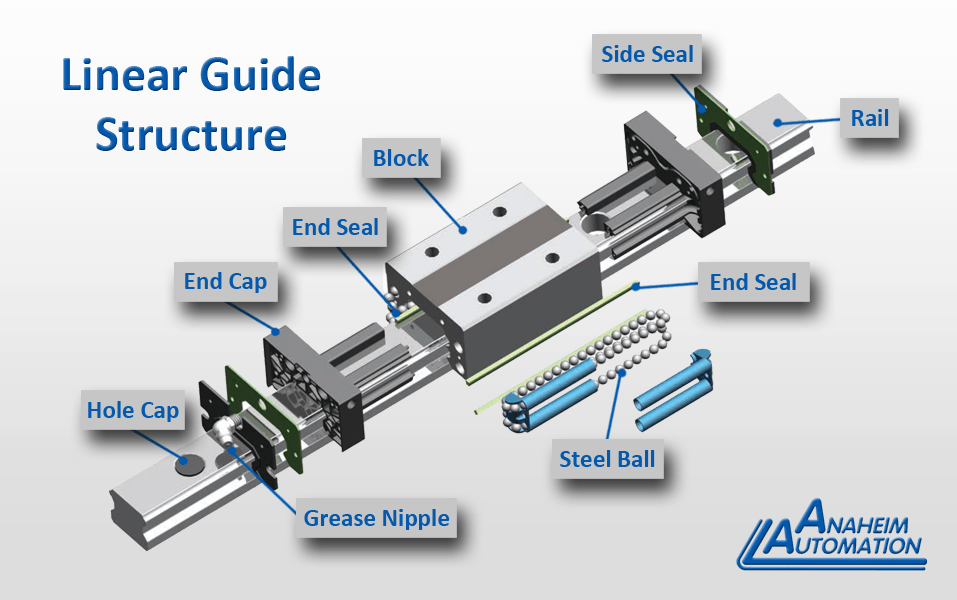

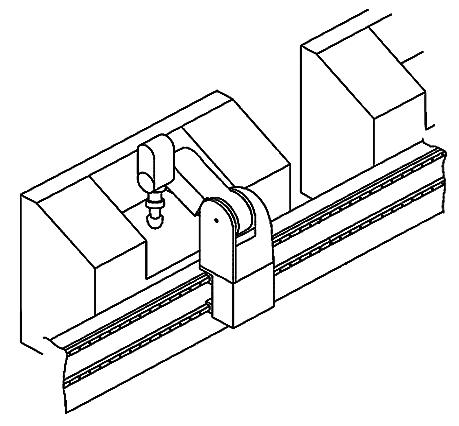

There are two parts to the Linear Guide System: the Linear Block and the Linear Rail. The linear guide blocks move down the length of the linear rail along the plane it was positioned for.

Also known as "linear bearings and rails," or "linear guideways," linear guide systems support and guide a load or mounted tool using precise, smooth linear motion.

Physical Properties Of A Linear Guide

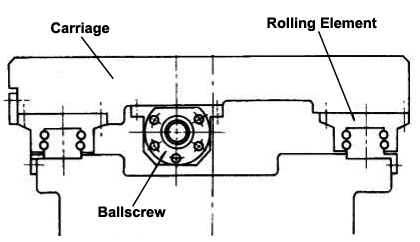

What Is A Linear Guide Block?

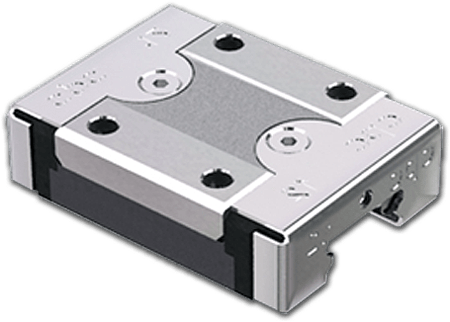

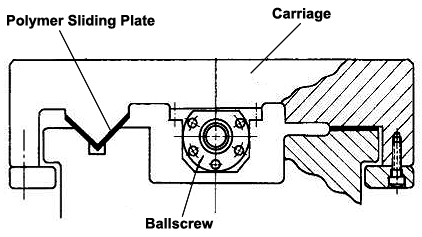

A linear guide block, or "carriage," is a component of a linear guide. This block is situated on the rail. Internal steel ball bearings minimize friction, allowing the block to travel up and down the rail smoothly. These bearings can be easily fall out if the carriage is opened, and they cannot be easily replaced once removed. It is therefore recommended that users not open the block. Linear carriages are most commonly made of carbon steel or stainless steel.

What Is A Linear Guide Rail?

The linear rail is the stationary component of a linear guide system. The block travels along the fixed rail, providing smooth motion along an X and/or Y axis. Linear rails can be mounted either horizontally or vertically. The length of the rail will determine the distance the block can travel. Rails can be butt-jointed together to increase overall length. The rail pitch is determined by the distance between the center of each hole along the rail. Linear rails are typically made of carbon steel or stainless steel.

Linear Guide Basics

Environmental Considerations

The environmental considerations pertaining to a linear guide rail carriage assemblies are dependent upon the intended application. However, there are a number of guidelines which should be followed for any linear guide.

Users should ensure a clean, debris free environment to prevent ingress into the re-circulating rolling elements. Dirt or dust on the rail can combine with the internal lubrication of these rolling elements causing a decrease in precision and efficiency, and possibly even damage.

For applications where a clean environment cannot be sustained at all times, an upgraded lubrication option can be added to a linear guide to help increase the lifetime of the guide and counteract the dirtier environment.

Required Maintenance

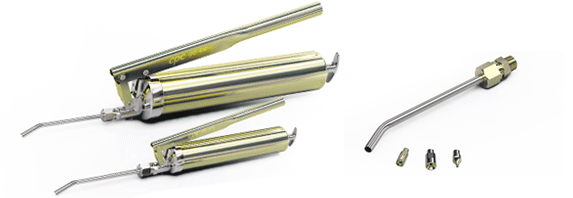

The chief maintenance requirement is to monitor and refill the grease lubrication when needed to ensure maximum life expectancy of the block. Most linear guides are equipped with an easily-accessed lubrication mechanism within the block. This provides a great advantage in allowing the user easy access for maintenance. Anaheim Automation offers convenient, easy-to-use grease and lubrication kits.

Linear Guide Lubrication Kit

Although proper lubrication is the most crucial part of linear guide maintenance, linear guides must also be thoroughly dusted and cleaned of unwanted debris that would cause the linear guide to deteriorate.

Estimated Lifetime

Linear guide operation and life can be optimized by adhering to industry best practices and standards. Lifetime expectancy can be estimated using the following formulas:

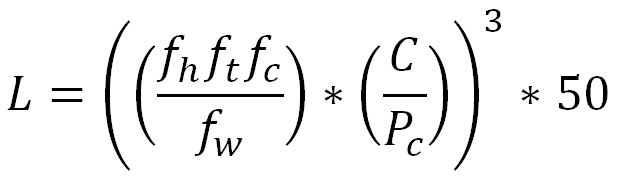

Nominal Life (L) for a Linear Motion System with Ball Bearings

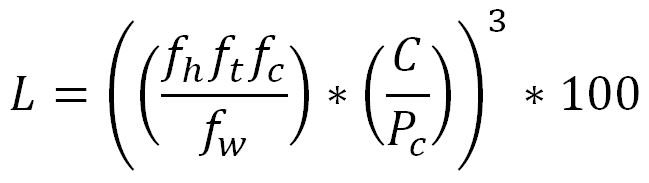

Nominal Life (L) for a Linear Motion System with Rollers

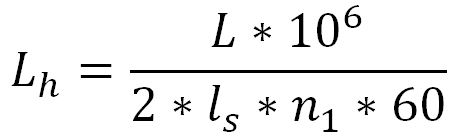

Service Life (Lh) of Linear Guide in Hours

Note:

C = Basic dynamic - Load Rating

fh = Hardness factor

Pc = Calculated Load

ft = Temperature Factor

fw = Load Factor

fc = Contact Factor

ls = stroke length (mm)

n1 = Number of reciprocating cycles per min (min-1)

Cost Of Linear Guides

The cost of linear guides is generally dependent upon factors such as the size and material of the linear guides. Light load applications require less rugged materials, therefore the components are typically less costly. For applications requiring higher load capacity, a larger and more rugged linear block is needed. The increased width of the block or length of the rail will raise the price of the linear guide components.

For specific pricing inquiries, including formal quotes with lead times, please contact one of our Sales Representatives at [email protected] or (714) 992-6990.

Types Of Linear Guides

The two types of linear guides which are most predominantly used in the motion control industry today are the sliding contact linear motion bearing and rolling element linear motion bearing guides. The main distinction between the two is the way in which the motion of the linear block proceeds along the linear rail.

Sliding Contact Linear Motion Bearing

The sliding contact linear guide is the oldest type of linear guide still used within the industry today. Because of the simplicity of their design and low in cost, companies still frequently use this older technology.

Sliding Contact Bearing

A major drawback of the sliding contact is the high coefficient of friction compared to other types. With such a high coefficient of friction this type of guide is not suitable for applications with high precision or high speed requirements. Additionally, the large amount of friction can cause excessive wear on the components, making it difficult to predict the estimated lifetime of the linear guides.

Rolling Element Linear Motion Bearing

Today, the rolling element linear guide is the most commonly used type for a majority of motion control applications. Ball bearings, or rollers, allow the blocks to move smoothly along the rail.

Rolling Element Bearing

Due to the use of these ball bearings, the coefficient of friction is significantly lower than that of sliding contact bearings, making rolling element linear guides easier to control, increasing accuracy, precision, and speed. These blocks are highly versatile, with a wide variety of options to choose from, making them suitable for nearly any linear motion application.

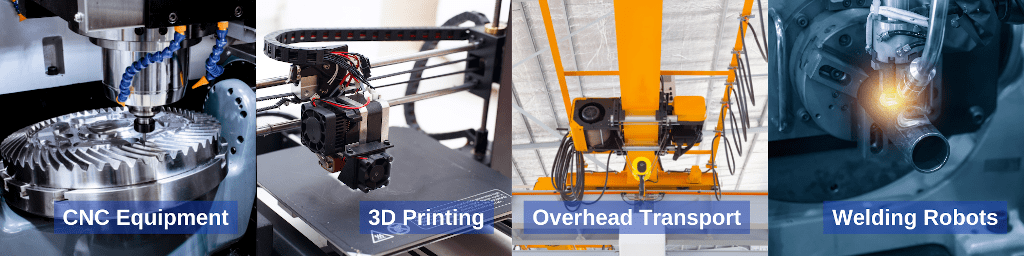

Where Are Linear Guides Used?

Where are linear guides used? Linear guides are used in a wide variety of industries including manufacturing, the machine tool industry, CNC and 3D printing, robotics, welding and cutting, diagnostic and laboratory equipment, pumps, processing machinery, and more.

Applications For Linear Guides

Appications which require high precision use linear guides due to their high accuracy and precision capabilities.

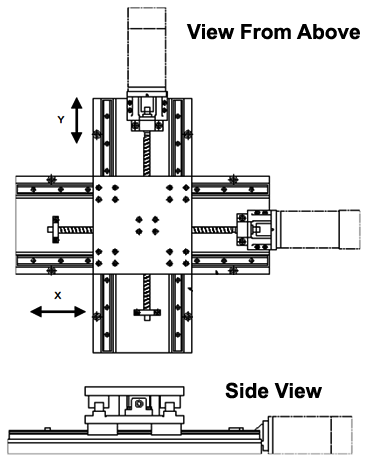

Single-Axis Linear Stage

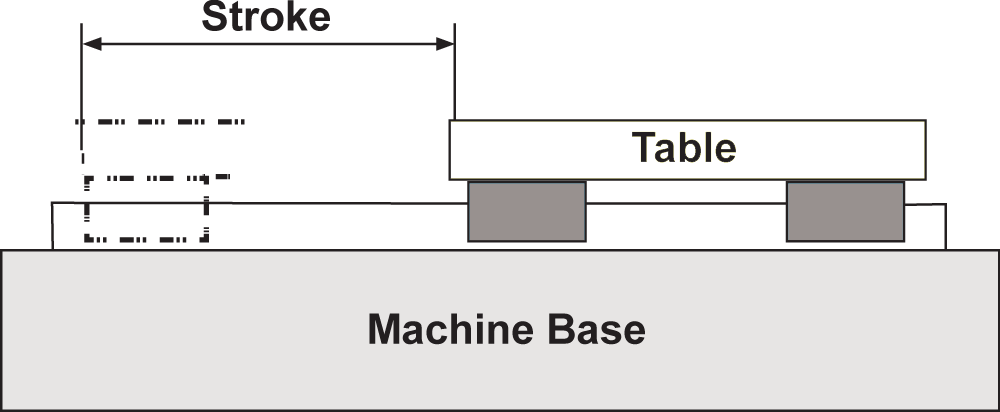

Linear guides are often used in linear stages to move a machine table along an X or Y axis.

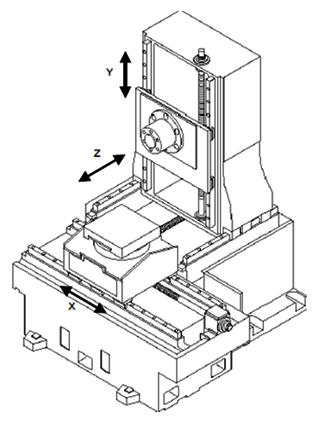

Horizontal Machining Center

Machine tool applications use linear guides because of their ability to manage temperature rise and high speed changes.

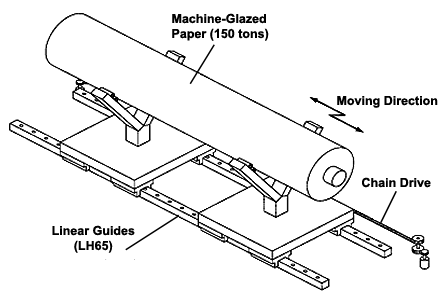

Heavy-Load Applications

Heavy load applications utilize linear guides to transport heavy product with ease.

Pick-and-Place Robot Application

Linear guides are used to help create the motion of a robotic pick-and-place machine.

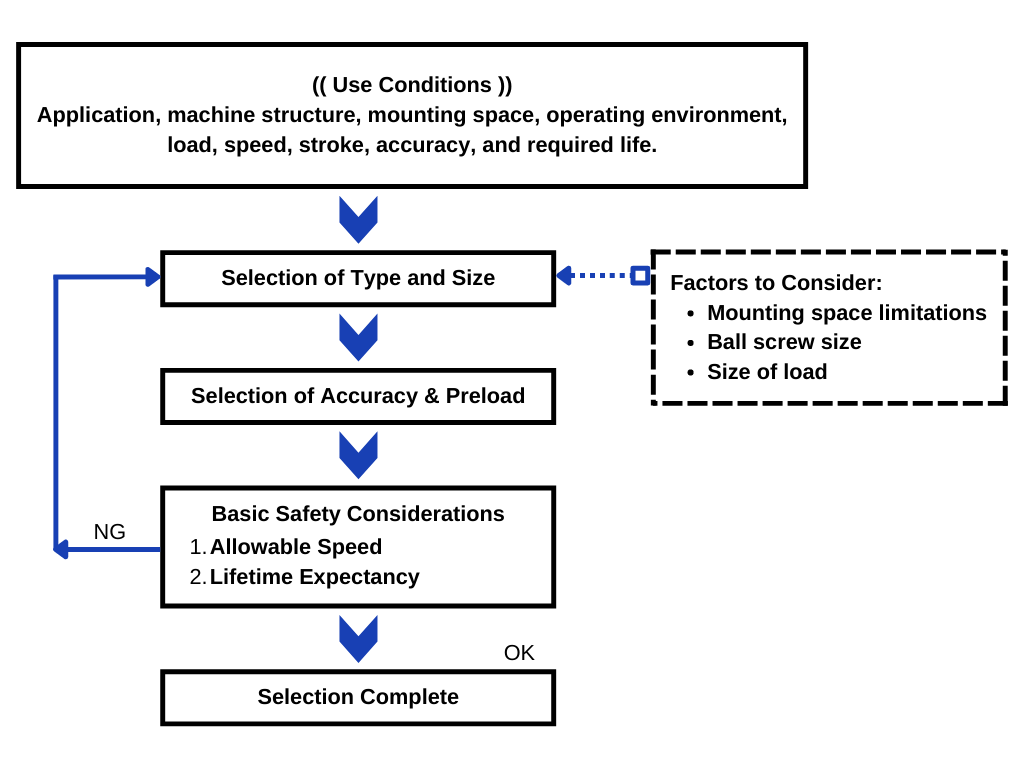

How To Select A Linear Guide

There are a several factors that should be considered when selecting a linear motion guide for your application. Following this flow chart will help guide you in choosing the perfect linear guide. Necessary equations are found within this guide for lifetime, max torque, etc.

Note 1: There might be limitations on the mounting space of the linear guide because of structural restrictions on the machine.

Note 2: In the case of a ball screw drive, it is advisable to choose a linear guide with its model number the same, as or closest to the ball screw shaft diameter.

Note 3: Applied load per ball slide herein shall be calculated simply by dividing total applied load by the number of ball slides.

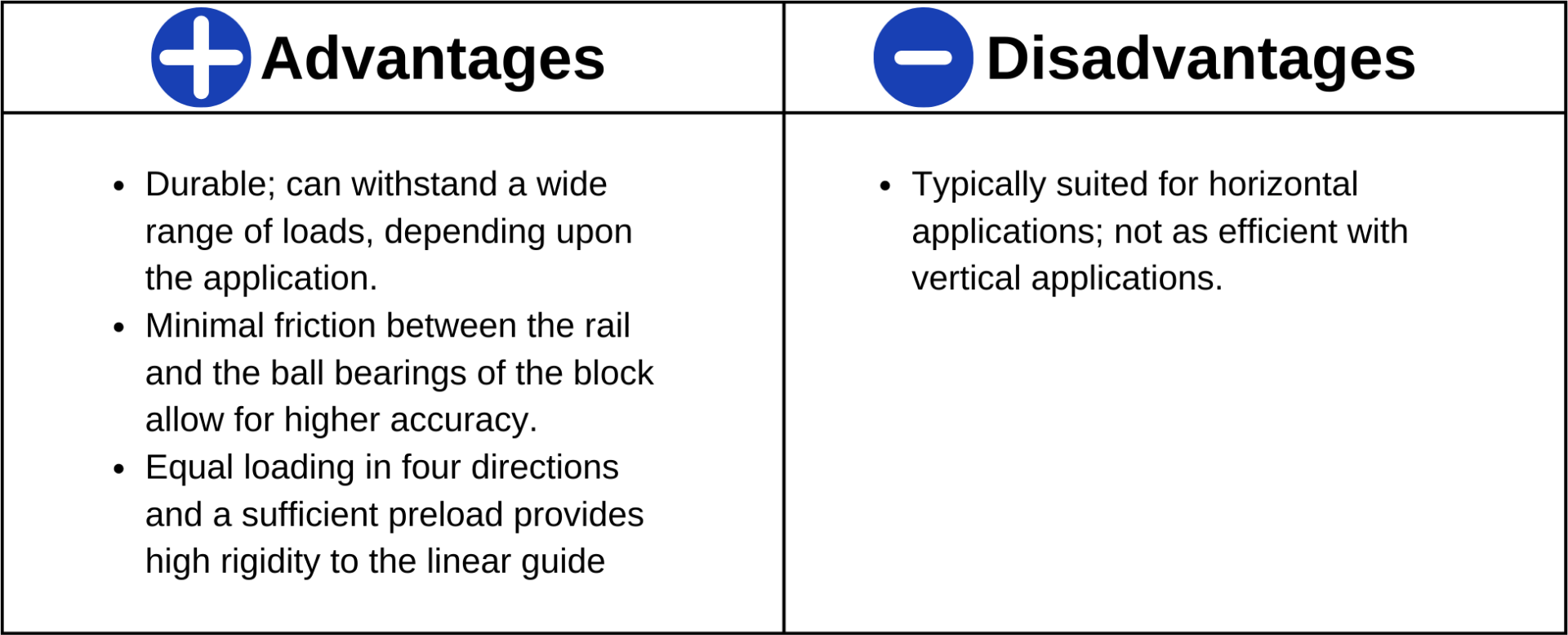

Advantages and Disadvantages Of Linear Guides

Troubleshooting Linear Guide Problems

There are a few common issues you'll want to avoid regarding your linear guide. Irregular use or unsuitable environments can cause corrosion of the rail, indentations in the rail, and other types of wear and tear can occur with linear guides. Damages can occur because of poor care of the system, excessive misalignment, contaminating the rail with the wrong lubrication, lack of lubrication, among other causes. The simplest way to avoid these problems is to regularly clean and maintenance the blocks and rails, as well as making ensuring proper installation from the outset.

History of Linear Guides

Primitive linear guides are thought to have been used going back as far as ancient Egypt. The modern linear guide, however, was patented in 1932. Steel was the first type of material used in the rolling elements because of its accurate and smooth linear movement. In 1946 a US company, Thomson Linear, first commercialized the rolling element in their ball screws with the first recirculation ball. In the following years, companies began innovating and evolving the linear guide into the product it is today.

Glossary

Accuracy – Based on the running accuracy of ball slides that travel on the rails, the required motion accuracy is expressed in a particular accuracy grade code, like P5 or PN, depending on the manufacturer.

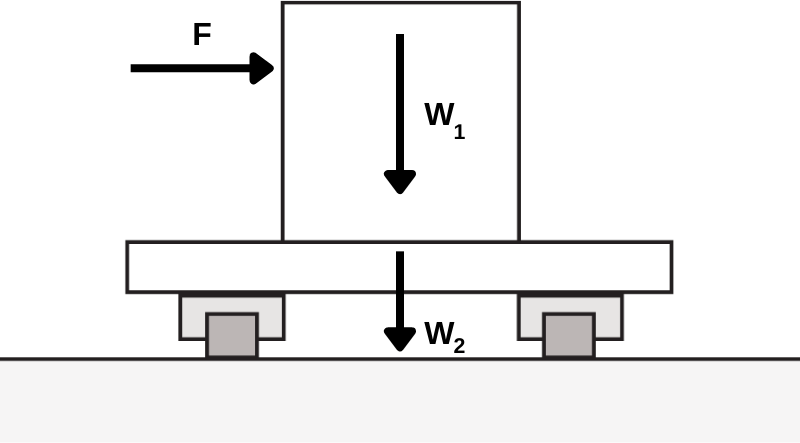

Applied Loads – These are the loads applied to the linear guides, which usually consist of self-weight of a table, weight of transported objects, and or forces that are working on a machine tool. The loads are normally applied vertically or laterally against motion axis.

Applied Loads

Application – This is the information on the type of machine (application) like machine tools, transporting systems, or measurement apparatuses for which linear guides are to be used. Generally, such information is very useful to select the appropriate linear guides.

Ball Bearings – Steel circular balls that create the motion for the linear guide system through its re-circulation.

Dynamic Load Capacity – The amount of force the linear guide can withstand when the block is in motion.

Grease – The class of lubricants applied to smooth the movement of guides and moving parts of the ball screw. Grease forms an oil film on metal surface to reduce wear and friction, thereby prolonging the life and preventing rust. Linear slides require periodic maintenance of grease according to their use conditions.

Linear Guide Block – The block that moves along the track that supports the machine or application it is holding. It houses the lubrication and the re-circulating bearings within the block.

Linear Guide Rail – The track that the block moves on, typically made of carbon steel. This track is a uniaxial track, meaning it travels only along one axis.

Load Moment – When the load acting upon the table extends beyond the table in the longitudinal, lateral or vertical direction, the linear slide receives a torsional force.

Machine Structure – This information covers the structure of machines and their relevant aspects of construction such as dimensions around the place where linear guides are mounted to, positions and directions of external forces, etc. This is compulsory information for selecting particular linear guides.

Pitch – The hole-to-hole distances found on the linear rails.

Required Life – Required life is expressed in a total travel distance (For example, 5000 km).

Service Life – The calculated time the linear guide can withstand before failure in hours.

Speed – This means a relative speed of the table (with the ball slides) against the rails. It is expressed as, for example, 100 m/min.

Static Load Capacity – The amount of force the linear guide can withstand when the block is not moving.

Stroke – This means a travel distance that a table mounted on ball slides is required to make.