We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Stepper Motor Guide

Table of Contents

Motor Basics: An Introduction to Stepper Motors

Stepper Motors

What is a Stepper Motor?

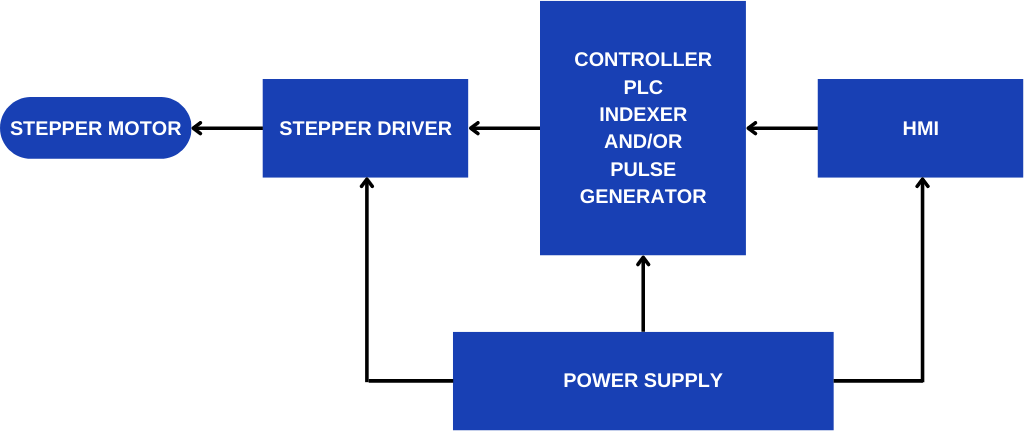

A stepper motor (also referred to as a step or stepping motor) is an electromechanical device achieving mechanical movements through the conversion of electrical pulses. Stepper motors are driven by digital pulses rather than a continuous applied voltage. Unlike conventional electric motors which rotate continuously, stepper motors rotate, or "step," in fixed angular increments. A stepper motor is most commonly used for position control. With a stepper motor/driver/controller system design, it is assumed the stepper motor will follow digital instructions. One important aspect of stepper motors is the lack of feedback to maintain control of position, which classifies stepper motors as open-loop systems.

Block Diagram for Stepper Motor System

Stepper Motor System Block Diagram

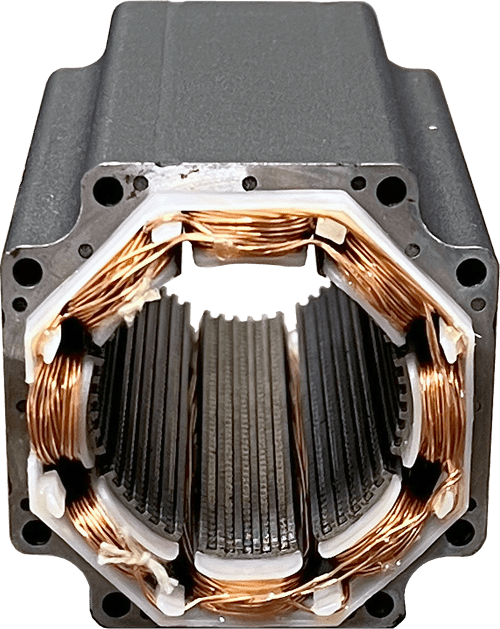

Physical Properties of a Stepper Motor

23Y210S-LW8 Stepper Motor Exploded Diagram

The main components of a stepper motor are the shaft, rotor and stator laminations, magnets, bearings, copper and lead wires, washers, and front and end covers. The shaft is typically made of stainless steel metal, while the stator and rotor laminations are comprised of silicon steel. Silicon steel allows for higher electrical resistivity, which lowers core loss. The various magnets available in stepper motors allow for multiple construction considerations. Magnets may be ferrite plastic, sintered ferrite and Nd-Fe-B bonded magnets. The bearings vary with motor size. The housing materials are composed of various other metals like aluminum, which provide high heat resistance.

How Does a Stepper Motor Work?

The main use of stepper motors is to control motion, whether linear or rotational. In the case of rotational motion, receiving digital pulses in a correct sequence allows the shaft to rotate in discrete step increments. A pulse (also referred to as a clock or step signal) can be produced by microprocessors, timing logic, a toggle switch or relay closure. A train of digital pulses translates into shaft revolutions. Each revolution requires a given number of pulses, each of which equals one rotary increment or step, which is only a portion of one complete rotation. There are numerous relationships between input pulses and the motor’s shaft rotation. One such relationship is that between the applied pulse sequence and rotation direction. When proper sequential pulses are delivered to the device, the shaft will undergo a clockwise or counterclockwise rotation. Another relation between the input pulses and motor's rotation is that between frequency and speed. Increasing input pulse frequency increases shaft rotation speed.

Basic Types of Stepper Motors

A stepper motor varies per application by construction and functionality. The three most common types of stepper motors are Variable Reluctance, Permanent Magnet, and Hybrid Stepper Motors.

Variable Reluctance (VR) Stepper Motors

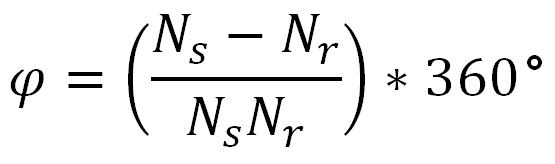

VR stepper motors are characterized as having multiple soft iron rotors and a wound stator. They generally operate on the basic principle of the magnetic flux finding the lowest reluctance pathway through a magnetic circuit. In general operation, VR stepper motors have relatively high step rates of 5 to 15 degrees and no detent torque. The step angles taken in VR stepper motors are related to the number of teeth contained within the stator and rotor. The equation relating these two variables can be found in the formula section of this guide.

How Does a VR Stepper Motor Work?

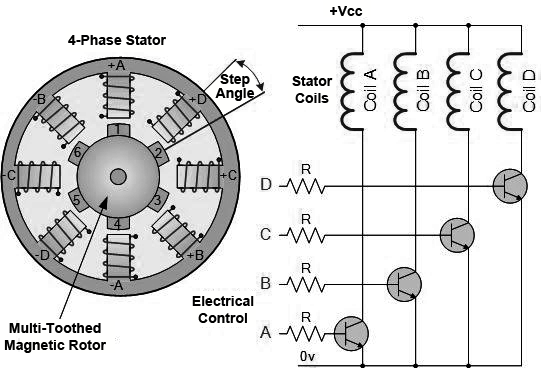

Referring to the diagram below, the poles become magnetized when the stator windings are energized with DC current. When the poles are magnetized, the rotor teeth become attracted to the energized stator poles and rotate to line up. Once the windings around stator phase A are energized, the rotor teeth become attracted to the stator poles, allowing the poles to line up. When phase A's windings become de-energized and phase B's are energized, the rotor rotates to line its teeth with those of the stator. This process continues in sequence with phase C, followed by phase D being energized, prompting the rotation of the rotor.

Variable Reluctance Stepper Motors

Brief Summary of VR Stepper Motors:

- The rotor has multiple soft iron rotors with a wound stator

- Least complex (and therefore least expensive) stepper motor

- Large step angles

- No detent torque detected in hand rotation of a de-energized motor shaft

Permanent Magnet (PM) Stepper Motors

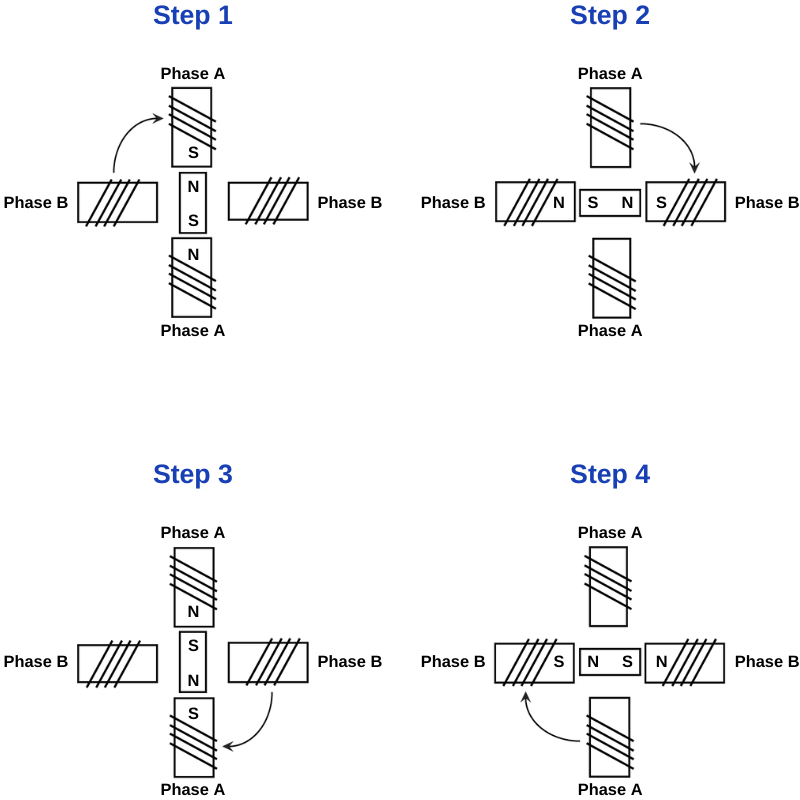

PM stepper motors consist of permanent magnet rotors with no teeth, which are magnetized perpendicular to the axis of rotation. By energizing the four phases in sequence, the rotor rotates due to the attraction of magnetic poles. The stepper motor shown in the diagram below will take 90 degree steps as the windings are energized in clockwise sequence: ABAB. PM stepper motors generally have step angles of 45 or 90 degrees and step at relatively low rates. However, they exhibit high torque and good damping characteristics. Anaheim Automation carries a wide selection of PM stepper motors, ranging from 15 to 57mm in diameter.

Brief Summary of PM Stepper Motors:

- The rotor is a permanent magnet

- Large to moderate step angle

- Often utilized in computer printers as a paper feeder

Hybrid Stepper Motors

Hybrid stepper motors incorporate the qualities of both the VR and PM stepper motor designs. With its multi-toothed rotor resemblance of the VR motor and an axially magnetized, concentric magnet around its shaft, the hybrid stepper motor provides an increase in detent, holding and dynamic torque. In comparison to the PM stepper motor, it provides performance enhancement with respect to step resolution, torque, and speed. Typical hybrid stepper motors are designed with step angles of 0.9°, 1.8°, 3.6° and 4.5°, with 1.8° being the most commonly used step angle. They are ideally suited for applications having stable loads with speeds under 1,000 rpm. Key factors which are taken into consideration when designing for optimal torque output of the motor are the number of laminations, precision and sharpness of teeth, and strength of magnetic materials.

Brief Summary of Hybrid Stepper Motors:

- Smaller step angles in comparison to VR and PM stepper motors

- Rotor is made of a permanent magnet with fine teeth

- Increase in detent, holding, and dynamic torque

- 1.8° is the most common step angle

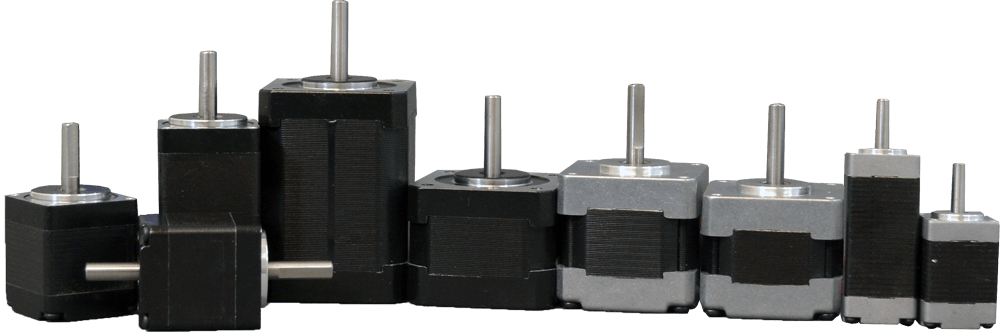

Note: At Anaheim Automation, the 1.8 degree hybrid stepper motor is the most widely stocked stepper motor, ranging in size from NEMA 08 to 42. The hybrid stepper motor can also be driven two phases at a time to yield more torque, or alternately one then two then one phase, to produce half-steps or 0.9 degree increments.

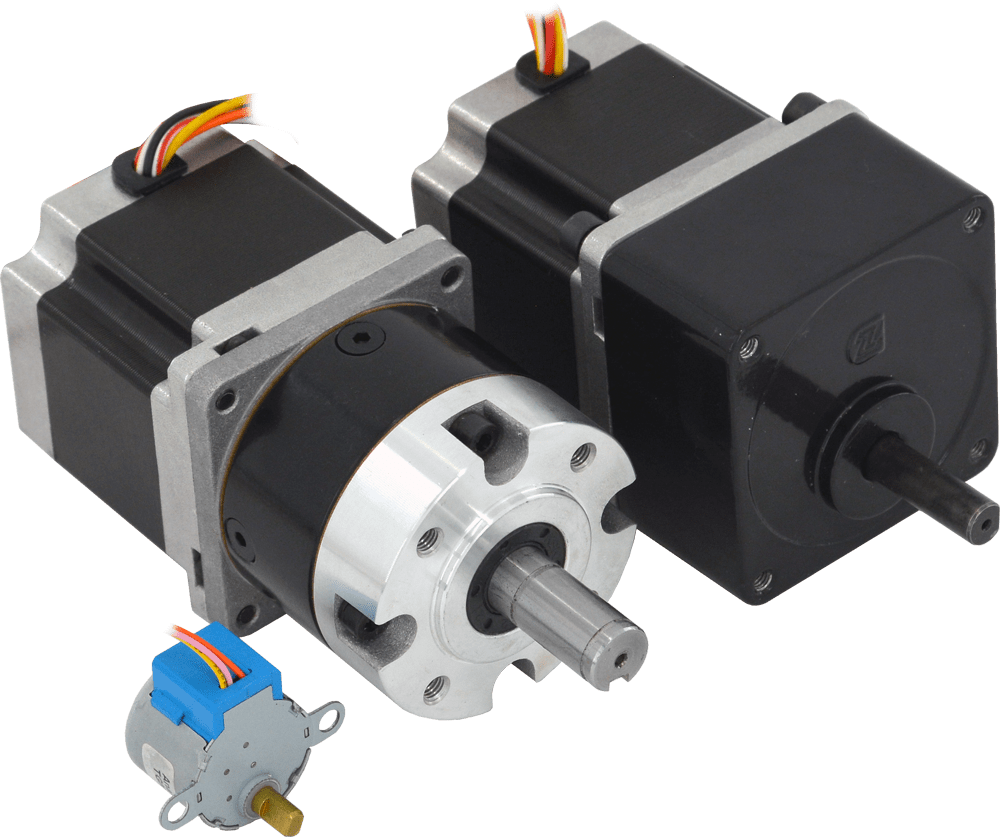

Stepper Gearmotors

The primary difference between individual stepper gearmotors is their performance characteristics. The main function of a stepper gearmotor is to convert the input of a stepper motor into an output with high torque and low RPM. Anaheim Automation carries both spur stepper and planetary gearmotors offering various gear ratios, stack lengths and torque outputs.

Stepper Motors with Spur Gearboxes

Stepper motors integrated with spur gearboxes are readily available, compact and efficient. Anaheim Automation's stepper gearmotors are available with gear ratios ranging from 3:1 to 150:1. Stepper motors with spur gearboxes are widely used in applications that require a speed increase or reduction and high output torque. When considering spur gearboxes, it is important to take into account the bore and shaft diameter and the gear center in order to meet specific application needs.

Stepper Motors with Planetary Gearboxes

Stepper motors integrated with planetary gearboxes are compact in size, efficient, and come in various stack lengths. The word "planetary" derives from the gearbox's resemblance to the solar system. This system consists of three main components: the sun gear, ring gear, and two or more planet gears. The sun gear is located in the center, the ring gear is the outermost gear, and the planet gears surround the sun gear inside the ring gear. The planetary gearbox is utilized in applications for low backlash, compact size, high efficiency, shock resistance, high torque to weight ratio, and improved lubrication.

How are Stepper Motors Controlled?

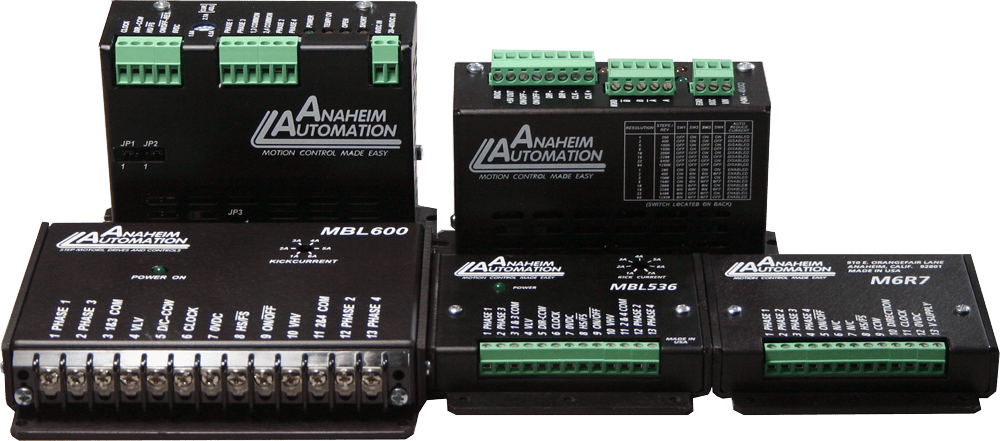

Stepper Drivers

A stepper motor performs the conversion of logic pulses by sequencing power to the stepper motor windings; generally, one supplied pulse will yield one rotational step of the motor. This precise control is provided by a stepper driver which controls speed and positioning of the motor. The stepper motor increments a precise amount with each control pulse, converting digital information into exact incremental rotation without the need for feedback devices such as tachometers or encoders. Since the stepper motor and driver are an open-loop system, problems such as feedback loop phase shift and resultant instability, common with servo motor systems, are eliminated.

How to Select a Stepper Motor

There are several important criteria involved in selecting the appropriate stepper motor:

- Desired Mechanical Motion

- Speed

- Load

- Stepper Mode

- Winding Configuration

With adequate logic pulses, stepper motors can be bi-directional, synchronous, provide rapid acceleration, run/stop, and interface easily with other digital mechanisms. Characterized as having low-rotor moment of inertia, no drift, and a noncumulative positioning error, a stepper motor is a cost-effective solution for many motion control applications. Generally, stepper motors are operated without feedback in an open-loop fashion and sometimes match the performance of more expensive DC servo systems. As mentioned earlier, the only inaccuracy associated with a stepper motor is a noncumulative positioning error which is measured in % of step angle. Typically, stepper motors are manufactured within a 3-5% step accuracy.

Motion requirements, load characteristics, coupling techniques, and electrical requirements need to be understood before the system designer can select the best stepper motor/driver/controller combination for a specific application. While not a difficult task, several key factors need to be considered when determining an optimal stepper motor solution. The system designer should adjust the characteristics of the elements under his/her control to meet the design specifications. Anaheim Automation offers many options in its broad line of stepper motor products, permitting maximum design flexibility. The result of having a large number of options is a high-performance system that is also cost-effective. Elements that need to be considered include the stepper motor, driver, and power supply selections, as well as the mechanical transmission, such as gearing or load weight reduction through the use of alternative materials. Some of these relationships and system parameters are described in this guide.

Inertial Loads

Inertia is a measure of an object's resistance to a change in velocity. The larger an object's inertia, the greater the torque required to accelerate or decelerate it. Inertia is a function of an object's mass and shape. A system designer may wish to select an alternative shape or low-density material for optimal performance. If a limited amount of torque is available in a selected system, then the acceleration and deceleration times must increase. We recommend that the ratio of the system inertia to the rotor inertia not exceed 10:1. A gearbox may be used to help achieve this ratio.

Note: The reflected inertia is reduced by a square of the gear ratio, and the output speed is decreased by a multiple of the gear ratio.

Frictional Loads

All mechanical systems exhibit some frictional force. The designer of a stepper motor system must be able to predict elements causing friction within the system. These elements may be in the form of bearing drag, sliding friction, system wear, or viscosity of an oil-filled gear box (temperature dependent). The selected stepper motor must be able to overcome any systemic friction while providing the necessary torque to accelerate the inertial load.

Note: Some friction is desired, since it can reduce settling time and improve performance.

Positioning Resolution

The positioning resolution required by the application may have an effect on the type of transmission used and/or selection of the stepper motor driver. For example: A lead screw with 5 threads per inch on a full-step drive provides 0.001 inch/step; half-step provides 0.0005 inch/step; a microstep resolution of 25,400 steps/rev provides 0.0000015 inch/step.

Stepper Motor Modes

Stepper motors are driven by waveforms which approximate to sinusoidal waveforms. There are three excitation modes commonly used with stepper motors: full-step, half-step and microstepping.

Stepper Motors: What is the Difference Between Full-Step and Half-Step Modes?

Stepper Motor – Full-Step (Two Phases are on)

In full-step operation, the stepper motor steps through the normal step angle, e.g. with a 200 step/revolution the motor rotates 1.8° per full step, while in half-step operation the motor rotates 0.9° per full step. There are two kinds of full-step modes: single-phase and dual-phase full-step excitation. In single-phase full-step excitation, the stepper motor operates with only one phase energized at a time. This mode is typically used in applications where torque and speed performances are less critical, wherein the motor operates at a fixed speed and load conditions are well-defined. Typically, stepper motors are used in full-step mode as replacements in existing motion systems rather than in new developments. Problems with resonance can hinder operation at some speeds. This mode requires the least amount of power from the drive power supply of any of the excitation modes. In dual-phase full-step excitation, the stepper motor operates with two phases energized at a time. This mode provides excellent torque and speed performance with minimal resonance issues.

Note: Dual excitation provides about 30 to 40 percent more torque than single excitation, but requires twice the power from the drive power supply. Many of Anaheim Automation's microstepping drivers can be set to operate at full-step mode if necessary.

Stepper Motor – Half-Step

The half-step excitation mode alternates between single and dual-phase operations, resulting in steps that are half the normal step size. Therefore, this mode provides twice the resolution. While the motor torque output varies on alternate steps, this is more than offset by the need to step through only half the angle. This mode had become the most predominately used by Anaheim Automation beginning in the 1970's, because it almost completely eliminates the potential for resonance issues. The stepper motor can operate over a wide range of speeds and drive almost any commonly encountered load. Although half-step drivers are still a popular and affordable choice, many newer microstepping drivers are cost-effective alternatives. Anaheim Automation's BLD76 series is a popular half-step driver and suitable for a wide range of stepper motors. This driver only requires a transformer, as the other power supply components are built into the driver itself.

Stepper Motor: Basics of Microstepping

Stepper Motor – Microstepping

In the microstepping mode, a stepper motor's natural step angle can be partitioned into smaller angles. For example, a conventional 1.8 degree motor has 200 steps per revolution. If the motor is microstepped in a 'divide-by-10' mode, then each microstep moves the motor 0.18 degrees, which becomes 2,000 steps/rev. The microsteps are produced by proportioning the current in the two windings according to sine and cosine functions. This mode is widely used in applications requiring smoother motion or higher resolution. Typical microstep modes range from 'divide-by-10' to 'divide-by-256' (51,200 steps/rev for a 1.8 degree motor). Some microstep drivers have a fixed divisor, while more expensive drivers allow for selectable divisors. For cost-effective microstep drivers, see Anaheim Automation's MBC and MLA Series.

Note: In general, the larger the provided microstep divisor, the more costly the driver will be. Should you prefer, Anaheim Automation also manufactures a series of Stepper Motors with Integrated Drivers, meaning the stepper motor and driver are in one unit. This design approach takes the guesswork out of motor and driver compatibility. For more information, please see the 17MD, 23MD and 34MD Series.

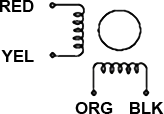

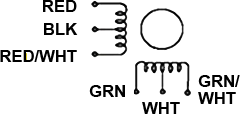

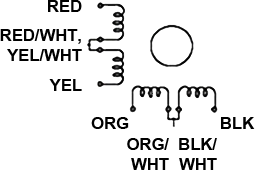

Motor Windings Configuration

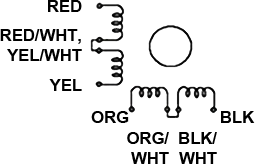

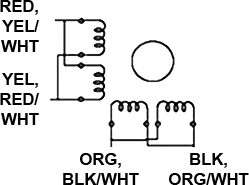

Internal Stepper Motor Windings

Stepper motors are wound on the stator poles in either a unifilar or bifilar configuration. The term unifilar winding refers to the motor winding configuration in which each stator pole has one set of windings; the stepper motor will only have 4 lead wires. This configuration can only be driven from a bipolar driver. The term bifilar winding refers to the winding configuration in which each stator pole has a pair of identical windings; the motor will have either 6 or 8 lead wires depending on termination. This configuration simplifies operation in that its transfer of current from one coil to another, wound in the opposite direction, reverses the rotation of the motor shaft. Unlike unifilar winding which only works with a bipolar driver, the bifilar configuration can be driven by either a unipolar or bipolar driver.

4-Lead Bipolar Connection

6-Lead Unipolar Connection

6-Lead Bipolar (Series) Connection

8-Lead Unipolar Connection

8-Lead Bipolar (Series) Connection

8-Lead Bipolar (Parallel) Connection

Formulas for a Stepper Motor

Step Angle Calculation Formula

Φ = Step Angle

Ns = Number of teeth on stator

Nr = Number of teeth on rotor

Steps per second = (rpm * steps per revolution)*60

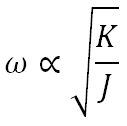

Resonant Frequency, Torque Stiffness, and Inertia

ω = Resonant frequency

K = Torque stiffness

J = Inertia

Advantages of a Stepper Motor

- Cost-effective*

- Simple designs

- High reliability

- Brushless construction

- Maintenance-free

- If windings are energized at standstill, the motor has full torque

- No feedback mechanisms required

- High acceleration and power rate

- A wide range of rotational speeds can be attained as the speed is proportional to input pulse frequency

- Known limit to the dynamic position error

*Stepper motor products vary in cost based on the criteria for each application. Some criteria include options of 0.9°, 1.8°, 3.6° and 4.5° step angles, torque ranging from 1 to 5,700 oz-in, and NEMA frame sizes of 08 to 42. Additional attachments such as cables and encoders can be purchased separately for an additional cost. With friendly customer service and professional application assistance, Anaheim Automation often surpasses customer expectations for fulfilling stepper motor and driver specifications, as well as other motion control needs.

Disadvantages of a Stepper Motor

- Low efficiency (motor attracts a substantial amount of power regardless of the load)

- Torque drops rapidly with speed (torque is inversely proportional to speed)

- Prone to resonance* (microstepping allows for smooth motion)

- No feedback to indicate missed steps

- Low torque-to-inertia ratio

- Cannot rapidly accelerate loads

- Gets hot in high-performance configurations

- Does not "pick up" after momentary overload

- Noisy at moderate to high speeds

- Low output power for size and weight

*Resonance is inherent in the design and operation of all stepping motors and occurs at specific step rates. Slow stepping rates, high rotor inertia, and elevated torque produce ringing as the rotor overshoots its desired angular displacement and is pulled back into position, causing resonance to occur. Adjusting any one of the three parameters –step rate, inertial load, or torque– can reduce or eliminate resonance. In general, the torque can be better controlled using microstepping. In microstepping mode, power is incrementally applied to the stator windings, resulting in a gradual build-up of torque which reduces overshoot and thereby resonance.

Where are Stepper Motors Used?

Although the stepper motor had been overshadowed previously by servo systems for motion control, it has increasingly emerged as the preferred technology in multiple areas. The major factor in this tendency towards the stepper motor is the prevalence of digital control, emergence of the microprocessor, improved designs (i.e. high-torque models), and lower cost. Today, stepper motors are used in applications all around us: printers (paper feed, print wheel), disk drives, clocks and watches, as well as factory automation and machinery. A stepper motor is most often found in motion systems requiring position control.

Anaheim Automation's cost-effective stepper motor product line is the wise choice for both OEM and user accounts. The line draws a diverse variety of customers: industrial companies designing or operating automated machinery or processes involving food, cosmetics or medical packaging, labeling or tamper-evident requirements, cut-to-length applications, assembly, conveyor, material handling, robotics, special filming and projection effects, medical diagnostics, camera tracking, inspection and security devices, aircraft controls, pump flow control, metal fabrication (CNC machinery), and equipment upgrades.

The stepper motor product line integrates a matched stepper motor, driver and controller in one unit. This design concept simplifies the selection process, thus reducing errors and wiring time. With friendly customer service and professional application assistance, Anaheim Automation often surpasses the customer's expectations for fulfilling stepper motor and driver specifications as well as other motion control needs.

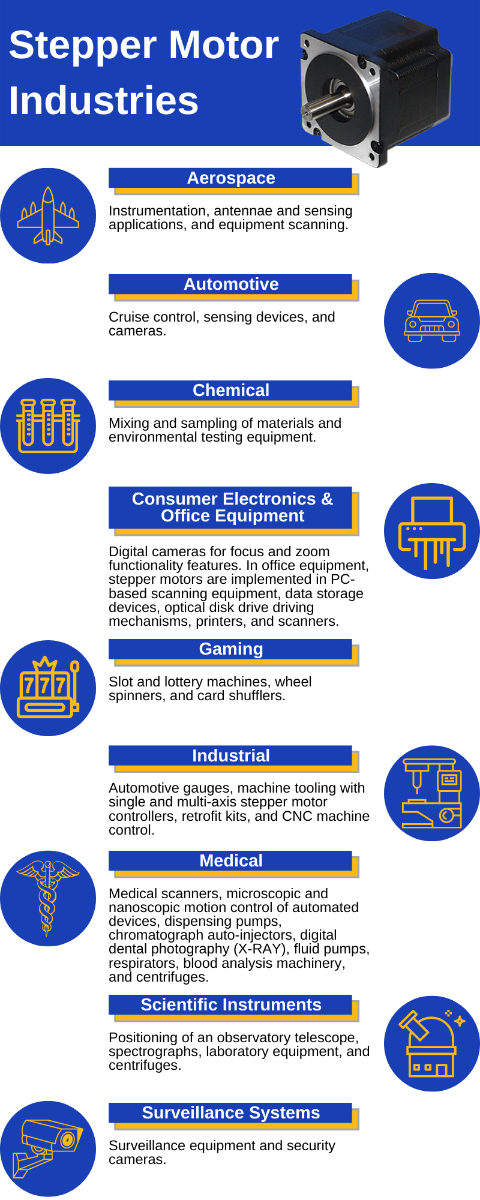

Stepper Motors are Used in Many Industries

Stepper motors have become an essential component to applications in several industries. The following is a list of such industries and their applications making use of stepper motors:

Accessories

Along with stepper motors, Anaheim Automation carries a comprehensive line of drivers and controllers, power supplies, gear motors, gearboxes, stepper motor linear actuators and integrated stepper motor/driver packages. Additionally, Anaheim Automation offers encoders, brakes, HMI, cables and connectors, linear guides and linear actuator tables/stages. If stepper motors are not ideal for your application, you might consider brushless DC, brush DC, servo, or AC motors, and their compatible drivers/controllers.

IP65 Rated Sealed Stepper Motors

Environmental Considerations for a Stepper Motor

The following environmental and safety considerations must be observed during all phases of operation, service, and repair of a stepper motor system. Failure to comply with these precautions violates safety standards of design and manufacture and intended use of the stepper motor, driver and controller. Please note that even with a well-built stepper motor, improperly installed and operated products can be hazardous. Precaution must be taken with respect to the load and operating environment. The customer is ultimately responsible for the proper selection, installation, and operation of the stepper motor system.

The atmosphere in which a stepper motor is used must be conducive to good general practices of electrical/electronic equipment. Do not operate the stepper motor in the presence of flammable gases, dust, oil, vapor or moisture. During outdoor use, the stepper motor, driver and controller must be protected from the elements by an appropriate cover while still able to provide adequate air flow and cooling. Moisture may create an electrical shock hazard and/or induce system breakdown. Due consideration should be paid to the avoidance of liquids and vapors of any kind. Contact the factory should your application require specific IP ratings. It is wise to install the stepper motor, driver and controller in an environment that is free from condensation, dust, electrical noise, vibration and shock.

Additionally, it is preferable to work with the stepper motor/driver/controller system in a non-static, protective environment. Exposed circuitry should always be properly guarded and/or enclosed to prevent unauthorized human contact with live circuitry. No work should be performed while power is being supplied. Do not plug in or unplug the connectors when power is ON. Wait at least 5 minutes upon turning power OFF before performing inspection work on the stepper motor system, because even after the power is turned off, there is still some electrical energy remaining in the capacitors of the driver’s internal circuit.

Plan for the installation of the stepper motor, driver and/or controller to take place in a system that is free from debris, such as that of metal from cutting, drilling, tapping, and welding, or any other foreign material that could come into contact with circuitry. Failure to prevent debris from entering the system can result in damage and/or shock.

Note: Anaheim Automation supplies IP65 Rated Sealed Motors, available for use in harsh environments.

Lifetime of a Stepper Motor

The typical lifetime of a stepper motor is 10,000 operating hours. This approximates to 4.8 years given that the motor operates one eight-hour shift per day. Motor lifetime may vary in regards to user application and how rigorously the motor is run.

To determine how long stepper motors last, factors such as duty cycle, load, eccentric load, and temperature must be considered. Duty cycle represents the elapsed time between operations of the stepper motor in hours per day, minutes per hour, or strokes per minute. Of course, heavier use will likely shorten the lifespan of a stepper motor, while lighter use will have the opposite effect. An eccentric load is a load in which the center of gravity does not go through the motor shaft axis. These types of loads cause binding and shorten the lifetime of a motor.

Bearings are typically the limiting factor for stepper motor lifespan, as they will fail before any of the other components, which could last almost indefinitely. Bearings can have a total lifespan of up to 20,000 hours. This estimate assumes normal use of about eight hours per day, five days per week. Thus, the lifetime of a stepper motor could reach 10 years, assuming proper operating conditions and high-quality bearings.

Staying within the limitations of the motor’s load capacity will help maintain its durability and lifetime. Exposing the stepper motor to extreme temperatures can greatly reduce the overall performance and life of the motor. In sum, managing the duty cycle, load, and temperature, will maximize the lifetime of a stepper motor. Always use a stepper motor within the manufacturer's specifications.

Required Maintenance for a Stepper Motor

Since stepper motors are brushless, they require no maintenance for wear and tear on brushes or commutators.

Stepper Motor Wiring:

The following information is intended as a general guideline for wiring the Anaheim Automation stepper motor product line. Be vigilant when you route power and signal wiring on a machine or system; radiated noise from the nearby relays, transformers, and other electronic devices can be introduced into the motor and encoder signals, input/output communications, and other sensitive low-voltage signals. This can cause system faults and communication errors.

Warning: Dangerous voltages capable of causing injury or death may be present in a stepper motor system. Use extreme caution when handling, wiring, testing, and adjusting during installation, set-up, tuning, and operation. Do not make extreme adjustments to the system parameters, as this can cause mechanical vibration and result in failure and/or loss. Once the stepper motor is wired, do not run the driver by switching On/Off the power supply directly. Frequent On/Off switching of power will accelerate aging of the internal components, reducing the lifetime of the system.

Strictly comply with the following rules:

- Follow the wiring diagram for each stepper motor

- Route high-voltage power cables separately from low-voltage cables

- Segregate input power wiring and stepper motor power cables from control wiring and motor feedback cables as they leave the driver. Maintain this separation throughout the wire run

- Use shielded cable for power wiring and provide a grounded 360 degree clamp termination to the enclosure wall. Allow room on the sub-panel for wire bends

- Make all cable routes as short as possible

Note: Factory-made cables are recommended for use in our stepper motor and driver systems. These cables are purchased separately and designed to minimize EMI. These cables are recommended over customer-built cables to optimize system performance and provide additional safety for the system and user.

Warning: To avoid the possibility of electrical shock, perform all mounting and wiring of the stepper motor and driver system prior to supplying power. Once power is supplied, connection terminals may have voltage present.

Note: Always read the specification sheet/user's guide accompanying each product.

Troubleshooting a Stepper Motor

Problem: Intermittent or erratic stepper motor or stepper driver function.

Solution: This is the most common cause of failure and one of the most difficult to detect. Start by ensuring that all connections between the stepper motor and the driver and controllers are tight. Evidence of discoloration at the terminals/connections may indicate a loose connection. When replacing a stepper motor, stepper driver or driver pack, or controller in a motion control system, be sure to inspect all terminal blocks and connectors. Check cabling/wiring for accuracy. Apply stress to the motor wiring to confirm that connections are secure and check the resistance with an ohmmeter. Whenever possible, use Anaheim Automation's shielded cables for stepper motor wiring.

Problem: Poor system performance (EMI problems, motor skipping steps intermittently/low repeatability, motor stalling, erratic behavior of the motor – run forward, run one direction then the other, wires heating up, possibly melting). If wires were lengthened, check the connection between the standard leads and the added length.

Solution: Check whether the wires/cables are too long and the connection between the wires. Keep the wires/cables less than 25 feet in length. For applications in which the length of wiring from the stepper motor to the driver exceeds 25 feet, please contact the factory for instructions, as it is likely that transient voltage protection devices will be required. Another possibility is that the motor’s lead wires are of a gauge too small. A common mistake is to match your cable wires to the gauge size of the lead wires. Anaheim Automation suggests using its shielded cable for such wiring purposes (purchased separately) to avoid this mistake. Additionally, check the age of your motor, as with time and use, stepper motors lose a portion of their magnetism which affects performance. Typically, one can expect 10,000 operating hours for stepper motors (approximately 4.8 years, running one eight-hour shift per work day) or as many as 20,000 operating hours assuming high-quality components and ideal operating conditions. Also, make certain your stepper motor/driver combination is a good match for your application. Contact the factory should you have any concerns.

Problem: The stepper motor is stalling.

Solution: In some cases, stalling of a stepper motor causes a large voltage spike that damages the phase transistors on the driver. Some drivers are designed to protect themselves from such occurrences. Otherwise, Transient Suppression Devices can be added externally. Consult the factory for further information.

Problem: The stepper driver is no longer working.

Solution: Disconnecting stepper motor wires while the driver is powered up creates a spike in current which gets fed to the driver and can cause it to fail. Avoid performing any service to the stepper motor, driver or controller while the power is on, especially in regard to the motor connections. This precaution is imperative for both the driver and the technician/installer.

Problem: The stepper motor has a shorted winding or a short to the motor case.

Solution: It is likely you have a defective stepper motor. Do not attempt to repair motors. Opening the motor may cause it to lose its magnetism, resulting in poor performance. Opening the motor case will also void your warranty. The motor windings can be tested with an ohmmeter. As a rule of thumb, if the stepper motor is a frame size of NEMA 08, 11, 14, 15, 17, 23, or 34 and the warranty period has expired, it is not cost-effective to return it for repair. Contact the factory if you suspect a defective motor that is still under warranty, or if the motor is a NEMA frame size 42 or a K-series motor.

Problem: Environmental factors are less than ideal.

Solution: Environmental factors such as electrical noise (due to welding, etc.), chemical vapors, moisture, humidity, dust, metal debris, etc., can damage the electronic components and the stepper motor. Protect drivers, controllers and stepper motors from environments that are corrosive, poorly ventilated, or contain voltage spikes. Anaheim Automation offers products in several line voltage ranges as well as splash-proof, IP65 rated stepper motors. For wash-down or explosion-proof motors, contact the factory directly. For AC lines containing voltage spikes, a line regulator (filter) will likely be required.

Note: For a detailed list of environmental considerations to keep in mind, visit Installation and Environment. If your application requires welding, or welding is performed in the same work environment, please visit Grounding and Shielding Tips for tips on reducing electrical noise or contact the factory for further advice on how to protect the stepper motor driver and controller.

Problem: The stepper motor is back-driving the stepper driver.

Solution: A stepper motor that is turned by a load creates a back EMF voltage on the driver. Higher speeds will produce higher voltage levels. If the rotational speed gets excessively high, this voltage may damage the driver. This is especially dangerous if the motor is back-driven while the driver is still on. Place a mechanical stop or brake in applications that could be subject to these phenomena.

Please note: Technical assistance regarding the Stepper Motor product line, as well as all the products manufactured or distributed by Anaheim Automation, is available at no charge. This assistance is offered to aid customers in their selection of Anaheim Automation products for a specific application. However, any selection, quotation, or application suggestion for a Stepper Motor or any other product offered by Anaheim Automation's staff, representatives or distributors is only to assist the customer. In all cases, determination of suitability of the custom Stepper Motor for a particular system design is solely the customers' responsibility. While every effort is made to offer solid advice regarding the Stepper Motor product line as well as other motion control products and to produce technical data and illustrations accurately, such advice and documents are for reference only and subject to change without notice.

Contact Us: Anaheim Automation has readily available applications engineers who are happy to help with most troubleshooting issues. Contact us for detailed assistance.

Stepper Motor FAQs

Q: Why is stepper motor size important? Is it possible to just choose a large motor size?

A: Stepper motor size is important because if the motor's rotor inertia predominately consists of the load, high resonance ensues and poses issues. Also, larger rotors require more time to accelerate/decelerate, and therefore, it is important to choose a motor size that is suitable for the application.

Q: While accelerating, why do stepper motors lose torque?

A: Inductance is the leading cause for motors losing torque at high speeds. The electrical time constant, Τ, is the amount of time it takes a motor winding to charge up to 63% of its rated value given a resistance R and an inductance L. With Τ=R/L, high inductance is not an issue at low speeds since current can easily and quickly flow through the motor windings. However, at high speeds, sufficient current cannot pass through the windings quick enough before the current is switched to the next phase, thereby reducing the torque provided by the motor. The current and number of turns in the windings therefore determine the maximum output torque in a motor, while the applied voltage and winding inductance affect the speed at which a given amount of torque can be produced.

Q: Why does increasing the voltage increase the torque if stepper motors are not voltage-driven?

A: Voltage can be viewed as forcing current through the coil windings. By increasing voltage, the pressure applied to force the current through the coil also increases. This in turn causes the current to build faster in the winding and be able to produce a larger magnetic field. This larger magnetic field produces more torque.

Q: What is the maximum operating temperature for stepper motors?

A: Most stepper motors include Class B insulation. This allows the motor to sustain temperatures of up to 130°C. Therefore, with an ambient temperature of 40°C, the motor has a temperature rise allowance of 90°C. Motors with class F insulation can sustain temperatures of up to 155°C. Class H insulated motors can sustain temperatures of up to 180°C.

Q: Is it possible to get more torque by running the stepper motor at double its rated current?

A: It is possible to increase torque by increasing the current, but doing so weakens the motor's ability to run smoothly.

Q: What is the difference between four, six and eight leads in motors?

A: Stepper motors have the ability to run in either parallel or series modes. In a parallel mode, only a four lead motor can be run, while in a series mode a six lead motor can be run. Eight lead motors can run in either parallel or series configurations. In applications where more torque is required at higher speeds, a lower inductance value provided by a four lead motor is a better choice.

Q: What is the difference between Unipolar and Bipolar motors?

A: A unipolar wound motor has six lead wires and windings that each have a center tap. Most applications implementing unipolar wound motors require high speed and torque. In contrast, a bipolar wound motor has four lead wires and no center tap connections. Most applications implementing bipolar wound motors require high torque at low speeds.

Q: What is the difference between an open-loop and a closed-loop stepper motor controller?

A: In an open-loop stepper motor controller, no feedback is going from the motor to the controller. This type of controller is effective when the motor is carrying a constant load at a steady speed. A closed-loop motor controller is more suitable for applications in which load or speed varies. In comparison to the closed-loop controller, the open-loop controller lacks complexity but is more affordable.

Q: When should I use microstepping?

A: Microstepping should be used when smooth rotation of the motor is desired. Since a microstepping motor moves by smaller increments, it has a higher resolution. Microstepping can be used to reduce the resonance of the system, since smaller step size reduces overshooting. Because a microstepping driver divides the current between phases, current builds up more gradually in the motor windings, resulting in more consistent torque and smoother motion. Microstepping is typically used in applications that require the motor to operate at less than 700 pulses per second.

Q: What do brakes do on a Stepper Motor?

A: Brakes do not slow the shaft of a motor and rather only hold it in place. If 24V is supplied to the brake, the brake is "released" and the shaft is free to spin. If 24V is not supplied, the brake locks position and holds the shaft in place.

Q: What is the difference between a round and square stepper motor?

A: A round (D and W series) motor utilizes an older design with a flatter T/S curve. It offers more torque at a higher RPM than the square (Y or L series) motor. The square motor offers more torque at a lower RPM.

Q: What is the recommended cable distance between Anaheim Automation stepper motors and drivers?

A: We advise that the wiring between stepper motors and drivers not exceed 25 feet in length. Although not required, we suggest using Anaheim Automation’s shielded motor cable. This cable is ideally suited to handle all driver/motor combinations that we offer. We can also add connectors to the cables. Please contact an Applications Engineer for more details.

Q: I have a motor with 4 leads plus a ground wire. Can I hook it up to Anaheim Automation’s products?

A: If the motor is a true 4 lead motor, you must look at specific driver/controller models that accommodate 4-lead motors. If it is a 6 or 8 lead motor that was modified to be used as a 4 lead motor, the ground wire is not required when the motor is grounded to the machine.

Q: If I apply too much load to a stepper motor and the shaft stops rotating, will I damage the motor?

A: No. The stepper motor will just stall. However, the drivers can be damaged if this stall condition lasts for long time periods.

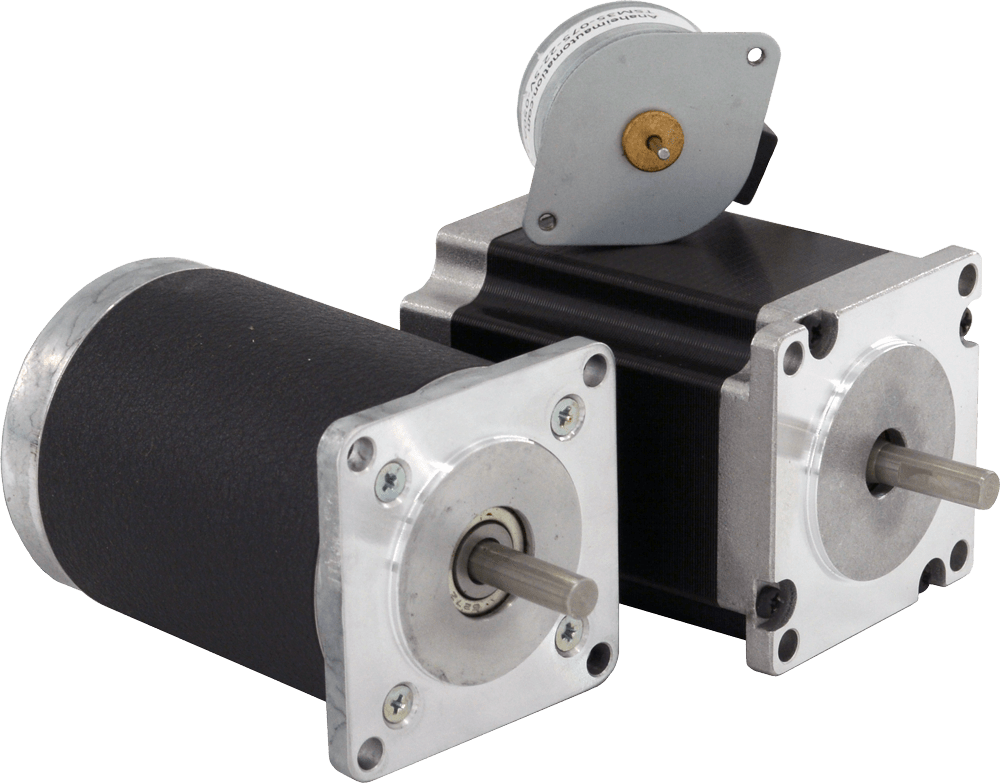

Q: Does Anaheim Automation sell encoders for stepper motors?

A: Yes. We supply encoders of any order size to customers who require a complete motor/encoder assembly ready to mount. Stepper motors with encoders are more effective at verifying motor position and detecting and preventing stalling of the motor. We can assemble the encoder to the motor for a nominal charge. Ask a Customer Service representative for more details.

Q: What is the life expectancy of Anaheim Automation’s Stepper Motors?

A: Anaheim Automation’s stepper motors have a 10,000-hour life expectancy under normal operating conditions. Anaheim Automation's warranty is 12 months after the invoice date. See the "Environmental Conditions" sections of the stepper motor guide for more details.

Q: What gauge wire should be used for a NEMA 34 stepper motor at 10 feet of distance?

A: Anaheim Automation’s motor cable is ideal. It is 18 gauge, 4 conductor with matching color code for the stepper motors. We can also add connectors if preferred. See the Accessories section of our web site for more details.

Q: How can I change the direction of my six-lead 23D309S standard round stepper motor without using the input on the driver for direction?

A: Reverse the Phase 1 (A) with the Phase 3 (/A) and the motor will run in the opposite direction.

Q: Can a disassembled stepper motor be cause for damage?

A: Yes! The result is up to 60% magnetizing loss if the rotor is pulled apart. If all parts are properly replaced, the motor can be remagnetized at the factory, but the charge is substantial. If you have a motor failure or are concerned about the performance, contact Anaheim Automation. Please note that the warranty period is 12 months from the date of invoice.

Q: Does Anaheim Automation have Permanent Magnet Stepper Motors?

A: Yes, ranging from 15 to 57 mm in diameter and 1 to 23 oz.-in. (model dependent) in torque. See PM Stepper Motors under the Stepper Motor category on our web site for more details and product specifications.

Q: Can I order a stepper motor with 3% accuracy instead of 5%?

A: Because almost all of our 5% rated stepper motors fall into the 3% accuracy category, we usually recommend that you order our standard motors. If you require a "guarantee" for the 3% accuracy, contact the factory for assistance.

Q: Does Anaheim Automation offer custom stepper motors?

A: Yes, we offer stepper motors with optional conduit box, keyway, and encoder-ready features. Some "special" motors are non-stock items that may require an NRE or SET-UP charge. Many Anaheim Automation stepper motors come standard with shaft-flat, conduit (terminal) box, and/or encoder-ready provisions, in which case there would be no additional fees for these features. Check the specification sheet and individual dimension drawings for details.

Q: I need a stepper gearmotor. Does Anaheim Automation offer these motors?

A: Yes. Anaheim Automation offers stepper motors with Planetary Gearboxes in NEMA sizes 11, 17 and 23. We also have stepper motors with Spur Gearboxes in NEMA sizes 23 and 34 and PM stepper gearmotors with 15 to 57 mm diameters. Visit the Stepper Gearmotor section of our web site for more details. Please Note: We also offer gearboxes and motors separately, should you not find your desired size or gear ratio.

Q: Does Anaheim Automation make stepper motors with drivers attached?

A: Yes. Anaheim Automation offers a line of Integrated Stepper Motors with Drivers and/or Controllers in NEMA sizes 17, 23 and 34.Check our 17MD, 23MD, and 34MD series for Integrated Motor/Drivers and our 17MDSI, 23MDSI, and 34MDSI series for our Integrated Motor/Driver/Controller product lines.

Q: Does Anaheim Automation have stepper motor-based linear actuators?

A: Yes, Anaheim Automation offers several types of stepper linear actuators, including:

- Hybrid: Non-Captive and External Linear types in NEMA sizes 11, 14, 17, 23, and 34

- Permanent Magnet: Captive types in 20mm to 57mm diameter frame sizes and Non-Captive types in 20mm to 42mm frame sizes

Q: Can I purchase an IP65 rated Stepper Motor?

A: Yes. Anaheim Automation offers an IP65 version for NEMA sizes 17, 23, 34 and 42 and torque ranges from 35 to 5,700 oz.-in. (model-specific). Visit our IP65 Stepper Motors to view our product line.

Q: Why is my stepper motor vibrating?

A: Resonance is inherent in the design and operation of all stepper motors and occurs at specific step rates. Slow stepping rates, high rotor inertia, and elevated torque produce ringing as the rotor overshoots its desired angular displacement and is pulled back into position, causing resonance to occur. Resonance can lead to vibration, noise, and lost steps. Reducing step size, adding mechanical dampers, or inserting gearboxes can all help minimize resonance. Step size can be reduced through microstepping, which can reduce overshooting and thereby resonance. Dampers aid in reducing inertial effects, which in turn reduces resonance. Gearboxes reduce resonance by “increasing the inertia of the motor side of the drive train.”

Q: Why is my stepper motor skipping steps?

A: Stepper motors can skip steps if the motor is producing resonance or if the motor's load inertia is large. If the acceleration of the rotor is slower than the rotation speed of the motor’s magnetic field, or the rotor’s average speed is higher than the rotation speed of the stator’s magnetic field, this could also lead to skipped steps. To avoid lost steps, be sure to select an appropriate driver. You may also try reducing step size, or adding a gearbox.

Q: Why is my stepper motor getting hot?

A: Stepper motors can get hot because the drive needs to supply the motor with full current at all times in order to maintain the position of the motor. Since the motor is consuming a lot of power, high amounts of heat may be generated. Some ways to prevent excessive heat generation are to reduce the holding or running current or use closed-loop control.

Stepper Motor Glossary

Bifilar Winding – refers to the winding configuration of a stepper motor in which each stator pole has a pair of windings; the motor will have either 6 or 8 lead wires depending on termination. This configuration can be driven from a unipolar or bipolar driver.

Clock – a pulse generator, which controls the timing of switching circuits that control the speed of the step motor.

Closed-Loop – a system with feedback control, such that the output is used to modify the input.

Controller (Stepper Motor) – the brains of a stepper system; it dictates and monitors the speed, direction and position of the motor by creating clock pulses and direction signals that are translated into phase currents and supplied to the motor by the driver.

Detent Torque – the holding torque when no current is flowing in the motor. The maximum torque which can be applied to the shaft of an unenergized step motor without causing rotation. The minimal torque present in an unenergized motor.

Driver (Stepper Motor) – often referred to as a translator or amplifier, drives a step motor based on pulses from a clock, pulse generator, or computer. Translates the train of pulses and applied power to the appropriate step motor windings.

Dynamic Torque – the torque developed by a motor while stepping at low rates.

Encoder – often called a pulse generator, is a feedback device for step motors. It consists of a disc, vane, or reflector attached to a step motor shaft to provide digital pulses which are sent to a translator and /or counters. This provides positional information if fed into a counter. Speed information may be derived if the time between successive pulses is measured and decoded.

Holding Torque – the maximum torque that can be externally applied to the step motor shaft without causing continuous rotation when one or more phases of the motor are energized.

Inertia – a measure of an object's resistance to a change in velocity.

Maximum Running Torque – the maximum torque load that the motor can drive without missing a step. This typically occurs when the windings are sequentially energized at approximately 5 PPS.

Open-Loop – refers to a motion control system in which no external sensors are used to provide position or velocity correction signals.

Permanent Magnet Stepper Motor – a step motor having permanent magnet poles.

Pole – the part of a magnetic circuit where a magnetic pole is generated either by a permanent magnet or windings.

Pulse – an electrical signal or voltage of short duration, used to convey intelligence.

Rated Torque – the torque-producing capacity of a motor at a given speed. This is the maximum torque the motor can deliver to a load and is usually specified with a torque/speed curve.

Resolution – the minimum positioning increment that can be achieved. It is frequently defined as the number of steps required for a motor's shaft to rotate one complete revolution. The reciprocal of the number of steps per revolution of the motor.

Rotor – the rotating part of the motor (the shaft may be included).

Stator – the stationary magnetic parts of the motor including the windings.

Step – movement of the rotor from one energized position to the next.

Step Angle – the nominal angle through which the shaft of a step motor turns between adjacent step positions. It depends on the motor and driving sequence (mode of drive).

Step Increment – an indication of step or motion size. Usually this is specified in degrees for a rotary motor and inches or millimeters for a linear motor.

Stepper (Stepping, Step) Motor – a digital actuator, which operates from discrete pulses (input signals) and produces motion in discrete increments. May be rotary or linear increments.

Step Position – the angular position that the shaft of an unloaded step motor assumes when energized. The step position is not necessarily the same as the detent position.

Teeth – projections on both the rotor and stator that produce a low reluctance magnetic path when aligned.

Torque – a force or couple tending to, or producing, rotation. Common step motor torque units are oz-in, N-m, or mNm.

Train Pulse – a series of spaced pulses.

Unifilar Winding – refers to the winding configuration of the stepper motor in which each stator pole has one set of windings; the stepper motor will only have 4 lead wires. This configuration can only be driven from a bipolar driver.

Variable Reluctance Step Motor – a step motor having only soft iron poles.