We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Gearbox Guide

Table of Contents

What is a Gearbox?

Industrial gearboxes, also called "gearheads" and "gear reducers," are mechanical devices which transfer energy from the driving device (usually a motor) to the rest of the system. The gearbox is mounted to the motor shaft and, through the internal configuration of mated gears within the housing, produces an increased output torque and decreased output speed.

Advancements in technology and the evolution of gear production have given rise to more efficient and powerful gearboxes being developed and manufactured at lower costs. From simple fixed-axis gear systems, toothed gear systems have evolved into new and improved gear styles including helical, bevel, spur, worm and planetary gear systems, each available in differing configurations such as in-line, right-angle, and rotating-flange styles.

- Low noise level

- High efficiency

- High reduction ratios

- Increased output torque

- Decreased output speed

- Durable

- More costly than other drive systems

- Proper lubrication and maintenance required for smooth operation

- Poorly cut teeth may result in excessive vibration and noise during operation

Physical Properties of a Gearbox

Most gearboxes are constructed from steel materials such as iron, aluminum and brass. Unlike other gearbox types, spur gearboxes can also be made with plastics such as polycarbonate or nylon. Other than the raw materials used, the orientation of the gear teeth play a major role in the overall efficiency, torque and speed of the system. Gearboxes with straight bevel gear teeth are typically used in low-speed applications, as they can be noisy and may have lower overall efficiency. Helical and spiral-bevel gearboxes are typically used in high-speed applications, as they are operate more quietly and with greater overall efficiency than straight gear teeth gearboxes.

How do Gearboxes Work?

All gearboxes operate on a similar principle: the direction in which the gears rotate depends on the input direction and orientation of the gears. For example, if the initial gear is rotating in a clockwise direction, the gear it engages will rotate counterclockwise. This continues down the line for multiple gears.

The combination of different gear sizes and the number of teeth on each gear plays a significant role in the output torque and speed of the shaft. High gear ratios allow for more output torque and lower speeds, while lower gear ratios allow for higher output speed and less output torque.

A planetary gearbox works in relatively the same way. A planetary gearbox system is constructed with three main components: a central sun gear, a planet carrier (carrying one or more planet gears) and an annulus (an outer ring). The central sun gear is orbited by planet gears (of the same size) mounted to the planet carrier. The planet gears are mated with the sun gear while the outer rings teeth mate with the planet gears.

There are several configurations for a gearbox system. Typical configurations consist of three components: the input, the output and one stationary component. For example, one possible configuration utilizes the sun gear as the input, the annulus as the output, with the planet carrier remaining stationary. In this configuration, the input shaft rotates the sun gear, the planet gears rotate on their own axes, simultaneously applying a torque to the rotating planet carrier that in turn applies torque to the output shaft (in this case, the annulus).

The rate at which the gears rotate (gear ratio) is determined by the number of teeth in each gear. So, adding a 3:1 gearbox to a motor with a speed of 300 RPM would result in an output speed of 100 RPM, with the output torque increasing inversely and proportionally. The torque (power output) is determined based on both the number of teeth and which component in the planetary system is stationary.

How are Gearboxes Controlled?

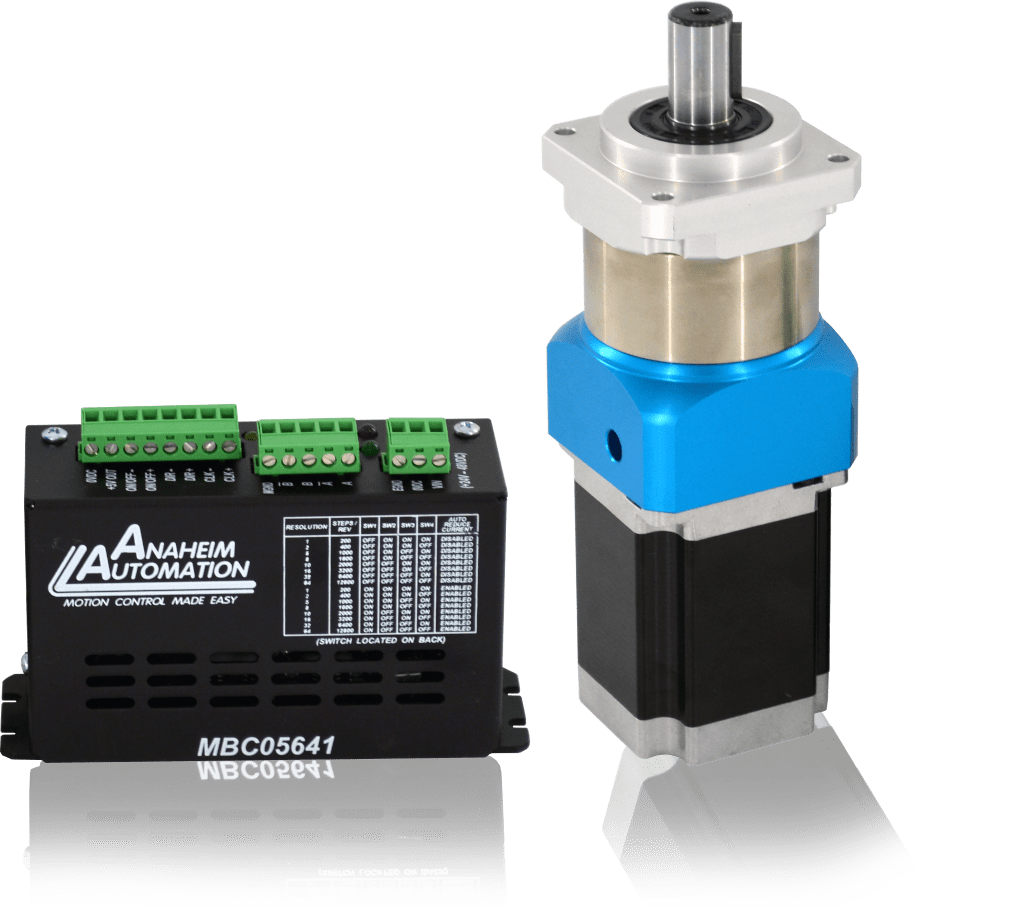

The output of a motor (i.e. Stepper, Brushless DC, AC, Servo, and Brush DC motors) is used as the input of the gearbox. The speed at which the gearbox rotates is entirely dependent upon the rotation of the motor shaft to which it is attached. Further, the motor's speed and direction are controlled by a driver. As a result, when the driver is powered, the motor shaft rotates inside the gearbox causing the output shaft of the gearbox to rotate. The final output speed and torque are dependent on the internal configuration of the gearbox.

NEMA 23 Stepper Motor with Controller and Gearbox

Where are Gearboxes Used?

Depending on the application requirements, different gearbox types may be more suitable than others. For example, planetary gearboxes are widely used in machine tool applications. Gearboxes of all types are used in a variety of industries:

Industries Where Gearboxes Are Used

- Aerospace – In the aerospace industry, gearboxes are used in space and air travel, i.e. airplanes, missiles, space rovers and vehicles, space shuttles, and engines.

- Agriculture – In the agriculture industry, gearboxes are used for plowing, irrigation, pest and insect control, tractors, and pumps.

- Automotive – In the automotive and transportation industries, gearboxes are used in cars, helicopters, buses, and motorcycles.

- Construction – In the construction industry, gearboxes are used in heavy machinery, such as cranes, forklifts, bulldozers, and tractors.

- Food Processing – In the food processing industry, gearboxes are used in conveyor systems, the processing of meat and vegetable products, packaging applications, and more.

- Shipping Industry – In the shipping industry, gearboxes are used in boats and yachts.

- Medical – In the medical industry, gearboxes are used in surgical tables, patient beds, medical diagnostic machines, dental equipment, and MRI and CAT scan machinery.

- Energy – In the energy industry, gearboxes are used in power plants, transformers, generators, and turbines.

| Type of Gearbox | Suitable Industries and Applications | Advantages | Disadvantages |

|---|---|---|---|

| Bevel |

Print Press Power Plants Automobiles Steel Plants Hand Drills Differential Drives |

Right angle configuration Durable |

Axes must be able to support forces Poorly cut teeth may result in excessive vibration and noise during operation |

| Helical |

Oil Industry Blowers Food and Labeling Cutters Elevators |

Can be meshed in parallel or cross orientation Smooth and quiet operation Efficient High horsepower |

Resistant thrust along axis of gear Additives to lubrication |

| Spur |

Cut-to-Length Packaging Speed Control Construction Power Plants |

Cost-effective High gear ratios Compact High torque output |

Noisy Prone to wear |

| Worm |

Mining Rolling Mills Presses Elevators/Escalator Drive Systems |

High precision Right-angle configurations Low noise Maintenance-free |

Nonreversible Low efficiency |

| Planetary |

Slewing Drives Lifts Cranes Machine Tools Automotive |

High power density Compact High efficiency in power transmission Greater stability Load distribution among planetary gears |

High bearing loads Inaccessibility |

Types of Gearboxes

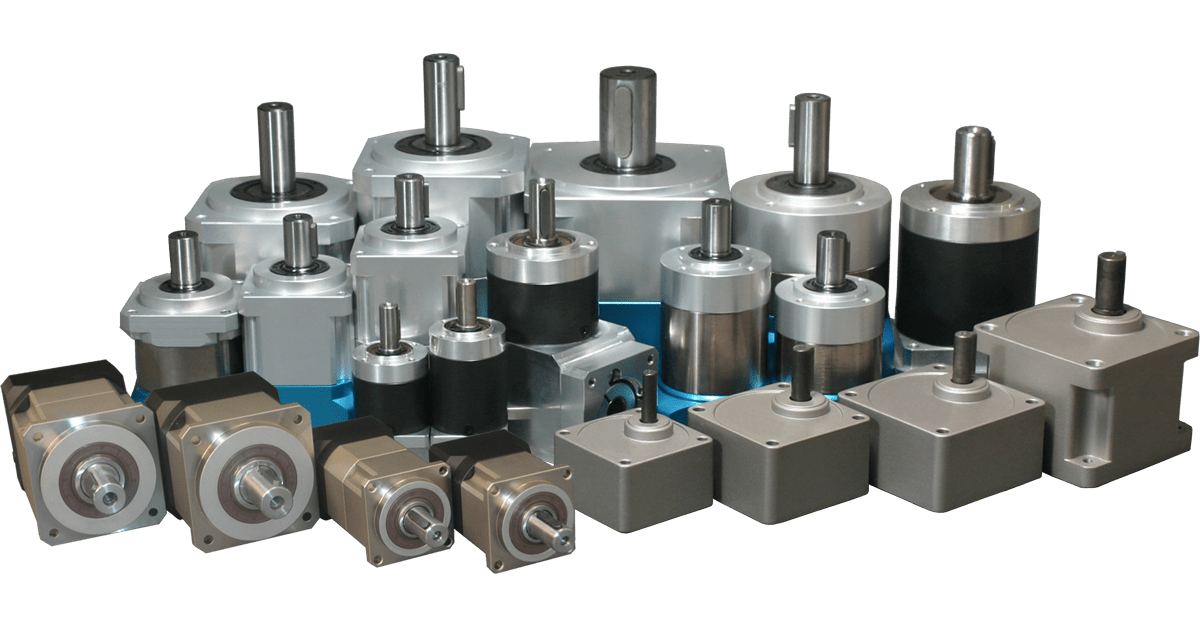

There are many types of gearboxes manufactured throughout the world. One of the main differences between individual gearboxes is their performance characteristics. Choosing from the various gearbox types is application dependent. Gearboxes are available in many sizes, ratios, efficiencies and backlash characteristics. All of these design factors will affect the performance and cost of the gearbox. There are several types of gearboxes:

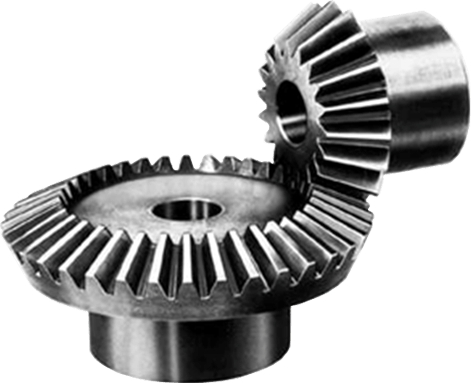

Bevel Gearboxes

Bevel Gears

Spiral Bevel Gears

There are two types of bevel gearboxes which include either straight or spiral teeth gears. Straight bevel gears have straight and tapered teeth and are used in applications requiring slow speeds. Spiral bevel gears have curved and oblique teeth and are used in applications requiring high-performance, high speed applications. Bevel gears are typically constructed from cast iron, aluminum alloy or other steel materials but vary between manufacturers. Bevel gearboxes are mainly used in right angle applications with the shafts in a perpendicular arrangement.

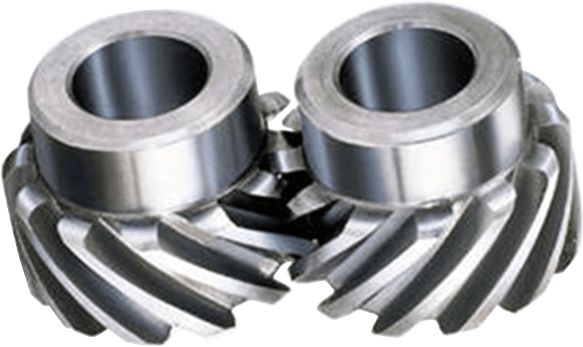

Helical Gearboxes

Helical Gears

Helical gears are cut at angles which allow for gradual contact between each of the helical gear teeth. This type of innovation provides for a smooth and quiet operation. Gearboxes using helical gears are applicable in high horsepower and efficient applications. Helical gears are typically constructed from cast iron, aluminum allow or iron material but may vary depending on the manufacturer. Helical gears are widely used in applications requiring efficiency and high horsepower.

Spur Gearboxes

Spur Gears

Spur gears are made with straight teeth mounted on a parallel shaft. The noise level of spur gears is relatively high due to colliding teeth of the gears which make spur gear teeth prone to wear. Spur gears come in a range of sizes and gear ratios to meet applications requiring a certain speed or torque output.

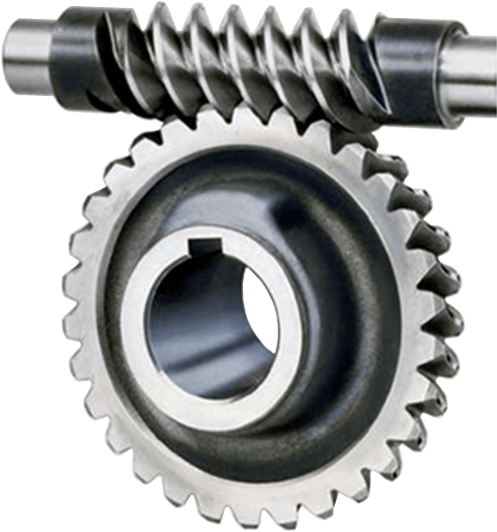

Worm Gearboxes

Worm Gears

Worm gears are able to withstand high shock loads, low in noise level and maintenance-free but are less efficient than other gear types. Worm gears can be used in right angle configuration. The worm gearbox configuration allows the worm to turn the gear with ease; however, the gear cannot turn the worm. The prevention of the gear to move the worm can be used as a braking system. When the worm gearbox is not active, it is held in a locked position. Worm gears are typically constructed of aluminum, stainless steel and cast iron. The material used varies depending on the manufacturer. Worm gears are used in heavy load applications requiring high speeds. These gearboxes can also be configured for right-angle applications.

Planetary Gearboxes

Sun Gear and Planetary Gears

Planetary gearboxes are so named due to their resemblance to the solar system. The components of a planetary gearbox include a sun gear, ring gear and planetary gears. The sun gear is the central gear which is fixed in the center, ring gear (annulus ring) which is the outer ring with inward-facing teeth, and the planetary gears which rotate around the sun gears and mesh with both the sun and ring gear.

Gearmotors

A gearmotor is a combination of an electric motor and a mounted gearbox, integrated into a simple package. A gearmotor combination reduces complexity, saves time in matching components, and lowers costs in designs requiring high torque low speed output. Gearmotors can be manufactured to be integral or be combined as separate components. Gearmotors which have the motor and gear reducer sharing the same shaft is what is meant by integral.

Gearmotors are used in many applications and industries, even in everyday household appliances. Industrial applications include cranes, lifts, jacks and conveyor machines. Everyday household appliances gearmotors are used in are washing machines, mixers, clocks, hand tools like drills and dryers.

Anaheim Automation offers a wide selection of stepper gearmotors, brushless gearmotors, brush DC gearmotors, and AC gearmotors integrated with either spur, planetary or worm gears.

How to Select the Appropriate Gearbox

When considering a gearbox, many factors need to be considered to meet specific application requirements:

Gear Ratio

Gear ratios are defined as the correlation between the number of teeth of two or more different gears. Typically, the number of teeth a gear has is proportional to its circumference. This means that the gear with a larger circumference will have more gear teeth. The relationship between the circumferences of the two gears can also give an accurate gear ratio. For example, if one gear has 36 teeth while another gear has 12 teeth, the gear ratio would be 3:1.

Output Torque

Output torque depends on the gear ratio used. To obtain a high output torque, a high gear ratio should be selected. This will lower the output shaft speed of the motor. Inversely, using a lower gear ratio will result in a smaller output torque value being delivered into the system, with a greater motor speed at the output shaft. This principle illustrates the inversely proportional relationship between torque and speed.

Speed (RPM)

Speed is inversely proportional to the gear ratio of the system. For example, the greater the number of teeth on the output gear, the greater the speed at the output shaft. Conversely, the more gear teeth at the output compared to the input, the lower the speed at the output shaft. In general, the output speed can be determined by dividing the input speed by the gear ratio. The higher the ratio the lower the output speed will be and vice versa.

Gear Arrangement

Gear arrangement offers various benefits over the traditional fixed axis gear system design. The unique combination of both power transmission efficiency and compact size allows for a lower loss in effectiveness. The more efficient the gear arrangement, (i.e. spur, helical, planetary and worm) the more energy will be transmitted and converted into torque, rather than energy lost as heat.

Another application factor to be taken into account is load distribution. Since the load being transmitted is shared among multiple planets, the torque capacity is increased. The higher number of planets in a gear system will increase the load ability and enhance torque density. Gear arrangements improve stability and rotational stiffness by creating a balanced system.

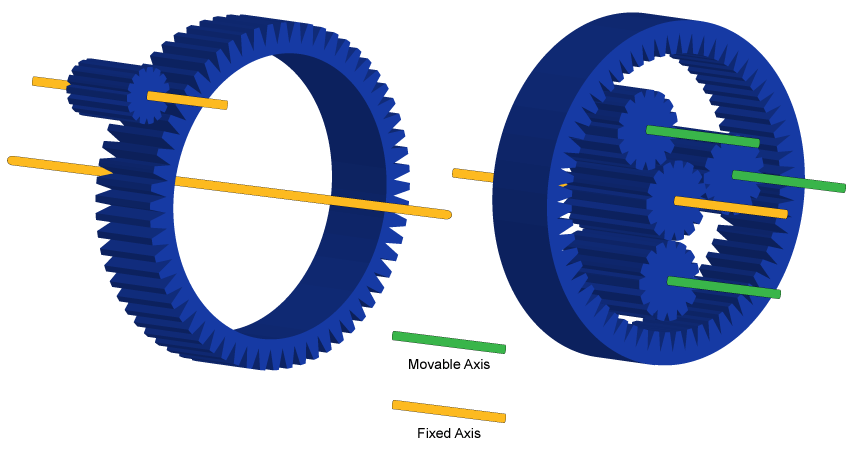

Fixed-Axis vs Planetary Gear System

In the figure above, the gear arrangement on the left is a traditional fixed axis gear system with a pinion driving a larger gear on an axis parallel to the shaft. On the right, is a planetary gear design system with a sun gear (pinion) surrounded by more than one gear (planet gears) and is encompassed in an outer ring gear. The two systems are similar in ratio and volume, but the planetary gear design has three times more torque density and three times the stiffness due to the increased number of gear contacts.

Planetary Gear System

Fixed Axis Gear System:

Volume = 1, Torque = 1, Stiffness = 1

Planetary Gear System:

Volume = 1, Torque = 3, Stiffness = 3

Other gear arrangements as mentioned in the Types of Gearboxes segment of this guide are bevel, helical, cycloid, spur and worm.

Backlash

Backlash is the angle at which the output shaft of a gearbox can rotate without either the input shaft or the gap between the teeth of two adjacent gears moving. It is not necessary to consider backlash for applications which do not involve load reversals, however in precision applications with load reversals (robotics, automation, CNC machines, etc.) backlash is crucial for accuracy and positioning.

For assistance with selecting the most suitable gearbox for your application, submit the Gearbox Application Sheet to our applications engineers.

Cost of a Gearbox

The price of a gearbox varies and is typically determined by size, accuracy specifications, backlash, and gear ratio. The cost for gearboxes with a backlash value under 5 arc-minutes will cost more than gearboxes with high backlash values. Anaheim Automation offers a broad line of gearbox products. Comprehensive specifications and pricing is available on our website for each of the offered types:

- Economy Gearboxes

- High-Grade Gearboxes

- Right-Angle Planetary Gearboxes

- Rotating Output Flange Gearboxes

Gearbox Formulas

Motor Torque * Gear Ratio * Efficiency = Output Shaft Torque

Example:

Motor Torque = 175 oz-in

Gear Ratio = 5 : 1

Efficiency = 0.95

175 * 5 * 0.95 = 831.25

Output Shaft Torque = 831.25 oz-in

Input Shaft Speed (RPM) / Gear Ratio = Output Shaft Speed

Example:

Input Shaft Speed = 1500 RPM

Gear Ratio = 5 : 1

1500 / 5 = 300

Output Shaft Speed = 300 RPM

Gear Ratio = Teeth on First Gear : Teeth on Second Gear

Example:

First gear has 60 teeth

Second gear has 20 teeth

Gear Ratio 60:20 (reduces to 3 : 1)

Gear Ratio = 3 : 1

Glossary

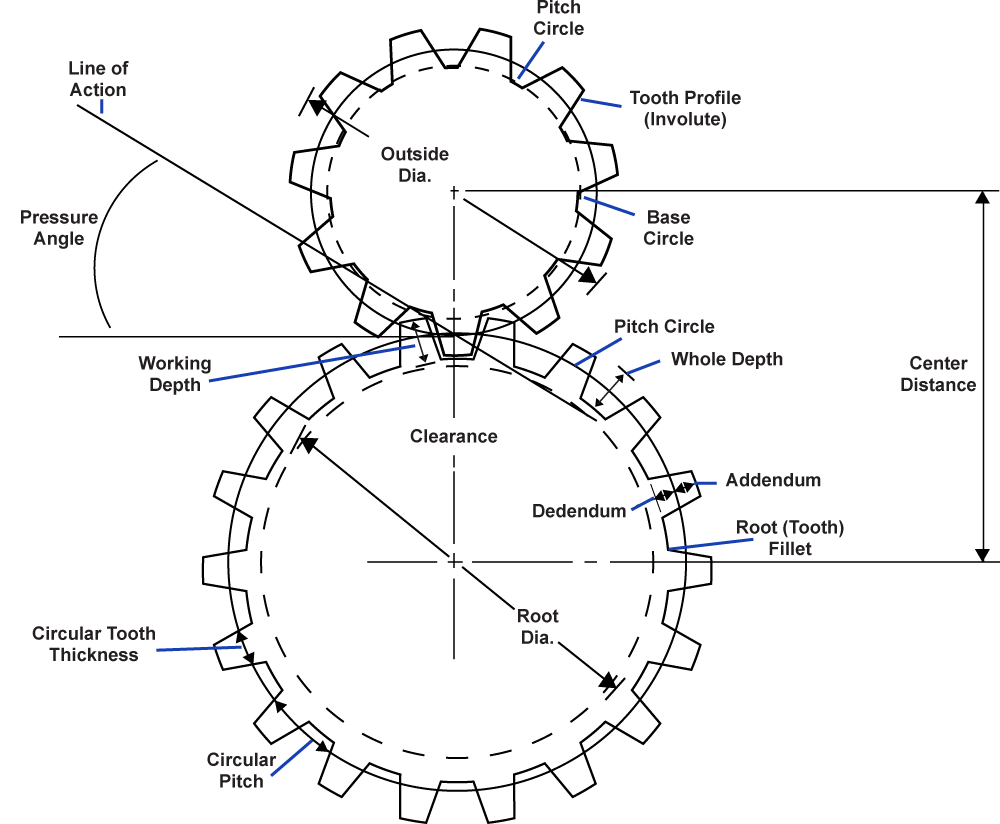

Addendum – the height of the gear tooth above the pitch circle diameter.

Backlash – the angle the output shaft of the gearbox can move without the input shaft moving.

Base Circle – an imaginary circle used in involute gearing to generate the involutes that form the tooth profiles.

Bevel Gears – used for right-angle applications. There are two types of bevel gears which are straight and spiral.

Bore – the diameter of the hole in a sprocket, gear, bushing, etc.

Center distance – distance between the axes of two meshed gears.

Circular Thickness – the thickness of the tooth on the pitch circle.

Dedendum – the depth of the tooth below the diameter of the pitch circle.

Diametrical Pitch – the teeth per inch of the diameter of the pitch circle.

Differential Gear – a bevel gear which allows two shafts to rotate at a different speed.

Gear – a wheel with teeth that meshes with another wheel with teeth to translate motion.

Gear Center – the center of the pitch circle.

Gear Ratio – the ratio between the numbers of teeth of meshing gears.

Gear Train – two or more gears meshed by their teeth. A gear train generates power speed through the meshed gears rotating.

Helical Gear – a gear with the gear teeth cut at angles.

Line of Contact – the line or curve along which two tooth surfaces are tangent to each other.

Involute – the curve which describes a line which is unwound from the circumference of the gear.

Pinion – a small cogwheel which fits into a larger gear or track.

Pitch Circle – the curve of intersection of a pitch surface of revolution and a plane of rotation.

Pitch Diameter – the diameter of the pitch circle.

Pitch Radius – the radius of the pitch circle.

Planetary Gears – a system that consists of three main components: the sun gear, ring gear, and two or more planet gears. The sun gear is the located in the center, the ring gear is the outermost gear, and the planet gears are the gears surrounding the sun gear inside the ring gear.

Pressure Angle – the angle between the line of action and the normal to the surface of the tooth.

Spiral Bevel Gears – shafts which are perpendicular to each other and are used in right-angle applications.

Spur Gear – connect parallel shafts which have involute teeth that are parallel to the shaft.

Sun gear – a gearwheel that rotates around its own axis and has other gears (planet gears) that rotate around it.

Torsional Stiffness – the measure of the amount of torque that a radial shaft can sustain during its rotation in a mechanical system.

Working Depth – the max depth a tooth of one gear extends into the tooth gear of mating gear.

Worm Gear – a gear with one or more teeth with screwed threads.