We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Revolutionizing Robotics: Integrated Servo Solutions

Revolutionizing Robotics: Integrated Servo Solutions

In today’s fast-paced industrial landscape, the demand for high-quality, cost-effective solutions with rapid delivery has never been greater. As the backbone of smart logistics and robotic process automation, mobile robots and AGVs (Automated Guided Vehicles) are leading the charge in reducing costs, maintaining top-tier quality, and boosting operational efficiency.

Driving Innovation in Integrated Mobility Solutions

With interest trending towards integration, miniaturization, and lightweight design, this innovation simplifies mobile robot chassis standardization, tackling the persistent cost challenges posed by custom solutions.

600kg Model: A Breakthrough from Concept to Reality

Launched at the end of 2022, Kinco’s first servo wheel was designed for 600kg medium-load mobile robots. Its highly integrated design not only simplifies mechanical engineering but also:

- Reduces installation space by 30%

- Cuts installation time by 80%

- Enhances maintenance efficiency

- Significantly lowers overall operational costs

The market response was overwhelmingly positive. Within just 18 months, the adoption rate for the iWMC solution in new 600kg models surpassed 60%, with tens of thousands of units shipped and widely recognized by clients for their performance and reliability.

1T Model: Scaling from One Innovation to Many

Building on the success of the 600kg model, this product line has expanded to meet diverse industry demands, from 10kg to 10-ton load capacities across sectors like photovoltaics, lithium batteries, 3C electronics, automotive, and packaging.

While scaling up presents challenges—such as increased structural complexity and stricter performance requirements—Kinco’s dedicated team rose to the occasion. Overcoming obstacles in drive algorithms, reducer adaptations, and production processes, we’re proud to introduce our latest innovation:

The iWMC Servo Wheel: Driving AGV Projects Forward

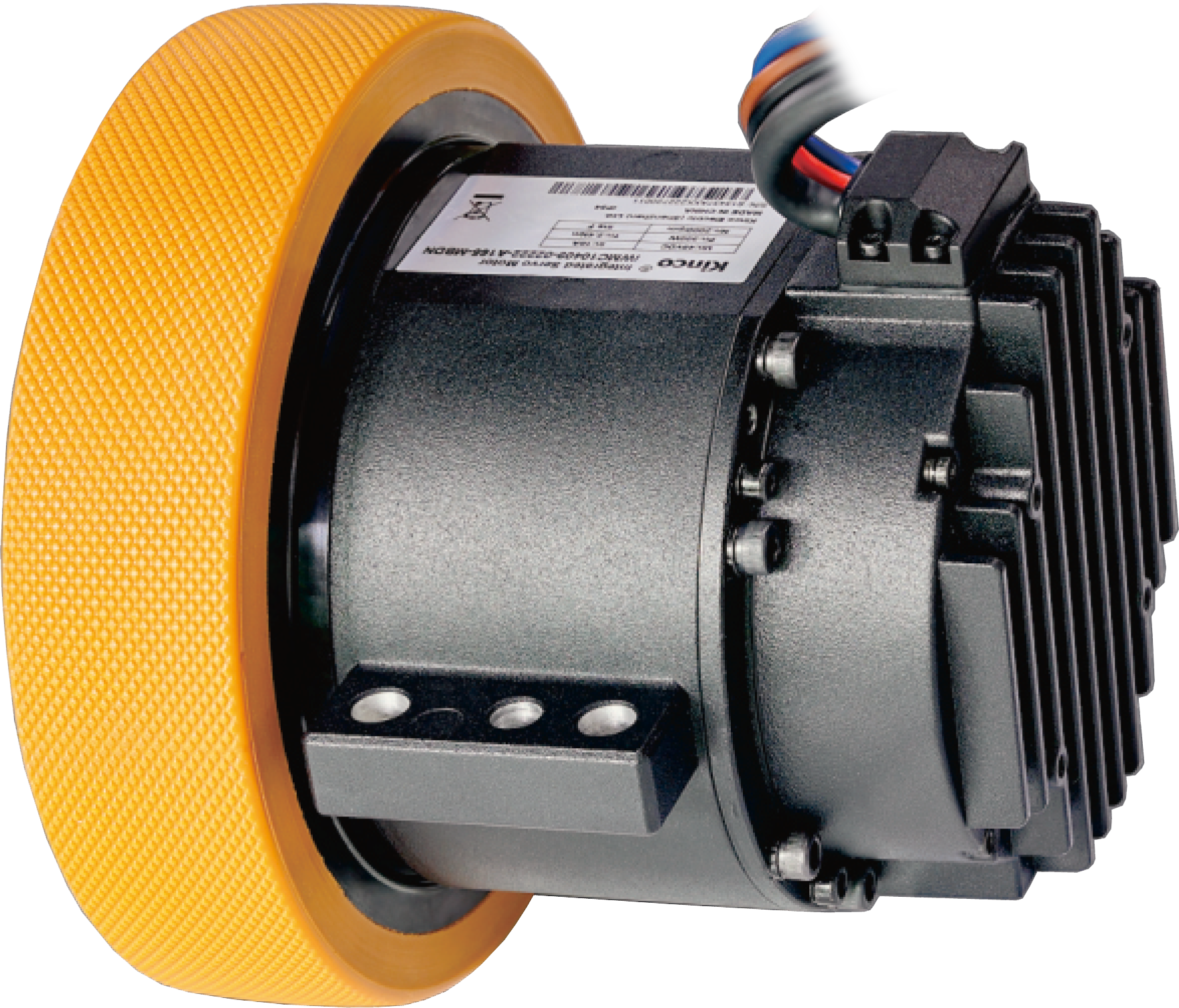

For Automated Guided Vehicle (AGV) applications, the iWMC Servo Wheel is the perfect solution. This integrated servo wheel combines a servo motor, drive, gearbox, and wheel into a single unit, making it incredibly easy to implement in AGV systems.

Key features of the iWMC include:

- All-in-One Solution: Integrates motor, drive, gearbox, and wheel to streamline AGV design.

- High Torque and Efficiency: Provides the power needed to move heavy loads with precision.

- Easy Integration: Simplifies installation and reduces setup time for faster development.

- Durability: Engineered to withstand the rigors of continuous AGV operation in industrial environments.

The iWMC is designed to enhance the performance and reliability of AGVs, making them an excellent choice for material handling, warehousing, and logistics applications.

iSMK Integrated Servo Motor: Compact Power for Robotic Process Automation

The iSMK Servo Motor with Integrated Drive is a game-changer for robotics applications. Combining the motor and drive into a single, compact unit, the iSMK simplifies system design and reduces the space required for installation. This makes it an ideal solution for robotic arms and other robotic integrations, where precision, efficiency, and space-saving designs are critical.

Key features of the iSMK include:

- Integrated Design: Reduces wiring complexity and minimizes installation time.

- High Precision: Delivers accurate positioning and smooth motion control, which are essential for robotics tasks.

- Compact Footprint: Perfect for space-constrained applications such as articulated robotic arms.

- Robust Performance: Engineered to handle the demanding environments typical in industrial robotics applications.

Whether you're building a new robotic system or upgrading an existing one, the iSMK offers unparalleled performance and simplicity.

Why Choose Our All-in-One Servo Solutions?

Anaheim Automation’s partnership with Kinco Automation brings cutting-edge technology to your automation projects. These all-in-one servo solutions are not only easy to install and operate, but also deliver the high performance and reliability that modern industrial applications demand.

Whether you're enhancing robotic systems with the iSMK Servo Motor or optimizing AGV performance with the iWMC Servo Wheel, these integrated solutions provide the efficiency, precision, and durability you need to stay competitive in the fast-evolving world of industrial automation.