We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

ENC-A3N-0100-079-H-M

| Cycles Per Rev (CPR) | 100 |

|---|---|

| Bore Size | 79 |

| Index Channel | No |

| Cover | H |

| Base | M |

| Lead Time | Typ 10 Days |

Product Information

The ENC-A3N, without index, is a high resolution single-ended encoder that requires a minimum shaft length of .445" and can be attached to shaft sizes ranging from .079" to 1" in diameter. The ENC-A3N provides digital feedback information for motion control applications that require position, speed and/or direction control.

Optical Encoder Module Update: This new transmissive optical encoder module was designed to be an improved replacement for the Avago HEDS-9000 series encoder module. This module is designed to detect rotary position when used with a code wheel. The new module consists of a lensed LED source and a monolithic detector IC enclosed in a small polymer package. The new module uses phased array detector technology to provide superior performance and greater tolerances over traditional aperture mask type encoders. The new module provides digital A & B quadrature outputs with an optional third output index channel. Each module is resolution specific and is matched to the resolution of a code wheel. All standard resolutions offered by the HEDS-9000 series encoder module, as well as additional resolutions, are now supported by the new module. The new module operates with a single 5V supply and provides single ended outputs which are capable of both sinking and sourcing 8mA at TTL levels. An internal 0.1 uF decoupling capacitor is designed into the new module to provide enhanced noise immunity over the HEDS-9000 series encoder modules. Physically, the new module has no external wire loops which can interfere when mounting. The connector pins are 0.051" shorter than HEDS modules, while still providing .30" insertion depth.

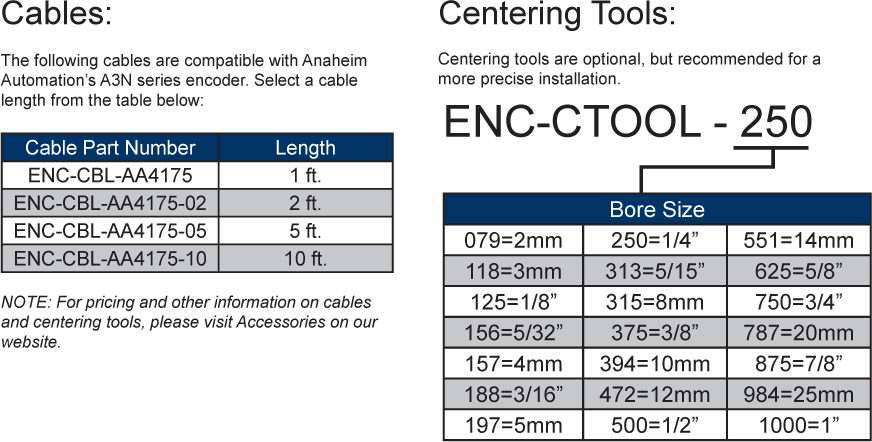

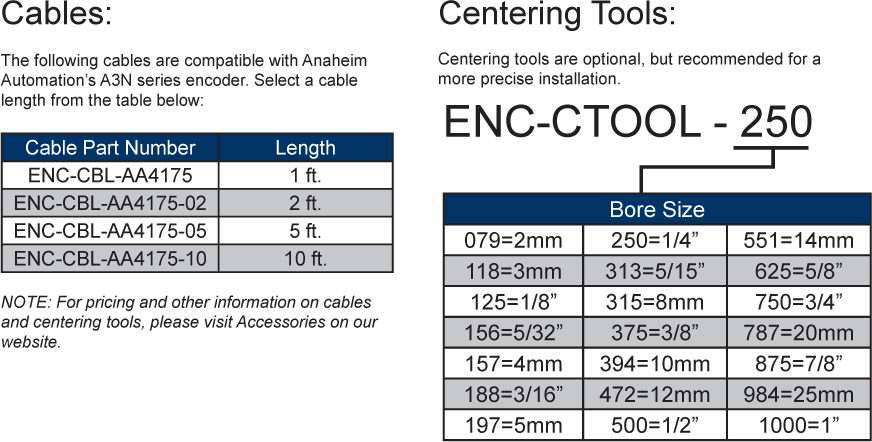

*Select a part number from the chart below or build your own part number using the Ordering Information tab at the bottom of the page. Cables and Centering Tools are also available. For instructions on installing your encoder to a motor, view our step by step video tutorial here.

- 64 to 2,500 Cycles Per Revolution (CPR)

- Tracks 0 to 300,000 Cycles Per Second

- 2-Channel Quadrature TTL Squarewave Outputs

- Operating Temperature of -40° to +100° C

- Powered From a Single +5VDC Power Supply

- Allows for ± .010" Axial Shaft Play

- RoHS Compliant and REACH Certified

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)