We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

ENC-A8TD-0200-197-H

| Cycles Per Rev (CPR) | 200 |

|---|---|

| Bore Size | .197" |

| Index Channel | No |

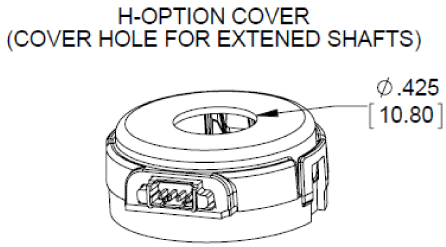

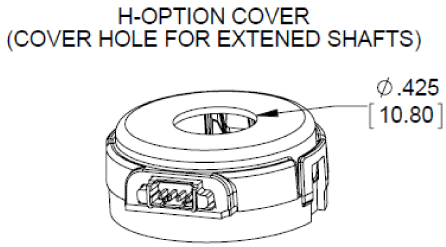

| Cover | Hole in Cover |

| Base | Default |

Product Information

With an acceptable minimum shaft length of .295" and maximum shaft length of .400", without the hole in cover. Shaft sizes ranging from .118" to .375" in diameter, the ENC-A8TD is a differential miniature encoder designed for high volume applications with space limitations. The ENC-A8TD module is designed to detect the rotary position with a code wheel. When attached to the end of a shaft, the encoder provides digital feedback information for motion control applications that require position, speed and/or direction control. This differential miniature encoder consists of an LED source lens and a monolithic detector IC enclosed in a small polymer package. These modules implement phased array detector technology providing superior performance and tolerances over traditional aperture mask type encoders. The ENC-A8TD series provides digital quadrature outputs on all resolutions and are capable of sinking or sourcing 8 mA each. These encoders are powered from a single +5 VDC power supply and are RoHS compliant.

*Select a part number from the chart below or build your own part number using the Ordering Information tab at the bottom of the page. ENC-CBL-CA-MIC6 Cables and Centering Tools are also available. For instructions on installing your encoder to a motor, view our step by step video tutorial here.

- Miniature Size

- 180 to 720 Cycles Per Revolution (CPR)

- Tracks 0 to 100,000 Cycles Per Second

- Fits Shaft Diameters of .118" to .375"

- Maximum Shaft Axial Play of ±.010"

- Operating Temperature of -20° to +100° C

- Powered from a Single +5 VDC Power Supply

- RoHS Compliant

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)