We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

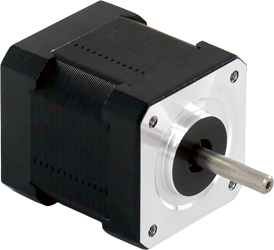

High-Torque (Square) Stepper Motors | Anaheim Automation, Inc.

Information

From Anaheim Automation's broad array of High-Torque Square-Frame Stepper Motors in a variety of sizes and torque ratings, customers can select the most suitable, cost-effective solution - sacrificing neither quality nor system performance.

- Sizes: NEMA 08, 11, 14, 15, 17, 23, 24, 34 and 42

- Torque: 2.5 to 5,700 Ounce-Inches

- 1.8° and 0.9° Square-Bodied, High-Torque Stepper Motors

- Up to Four Stack Lengths, Several Windings in Each Frame Size

- Conduit Box or Four, Six, or Eight Lead Wires (model dependent)

- Customization and Value-Added Motor Accessories Available

- Drop-In Replacement for Most Competitors at Huge Savings!

Featured Series

Models range from the smallest 08Y series of NEMA 08 frame size step motors which produce up to 4.2 oz-in of torque, to the largest 42K series of NEMA 42 frame size step motors which produce up to 5,700 oz-in of torque. Motors are available in either 1.8° or 0.9° step angles and with either four, six, or eight lead wires or a conduit box. (These features are all model dependent).

Custom motor windings, shaft modifications, and value-added encoder, brake, gearbox, connector, and cable options are available upon request. Contact our engineers to discuss your application requirements.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)