We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

How to Integrate a Kinco HMI Into Your System: A Step-By-Step Guide

How to Integrate a Kinco HMI Into Your System: A Step-By-Step Guide

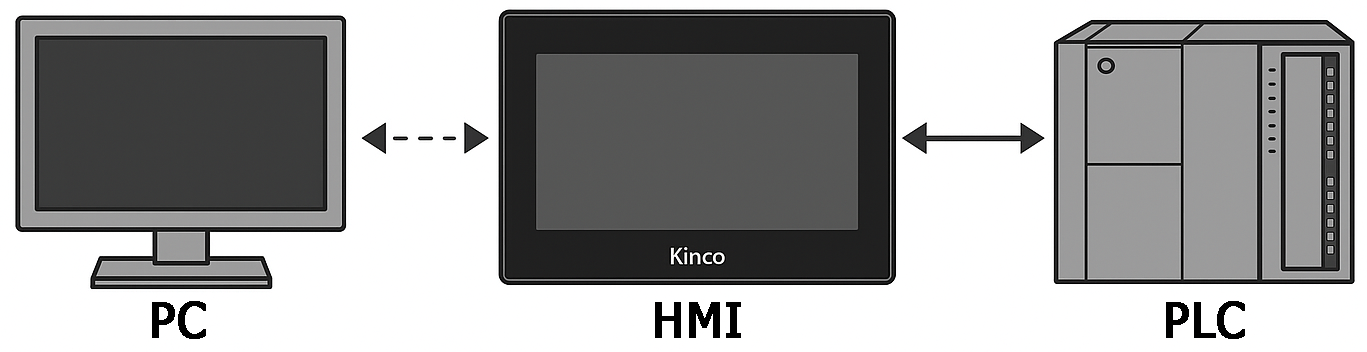

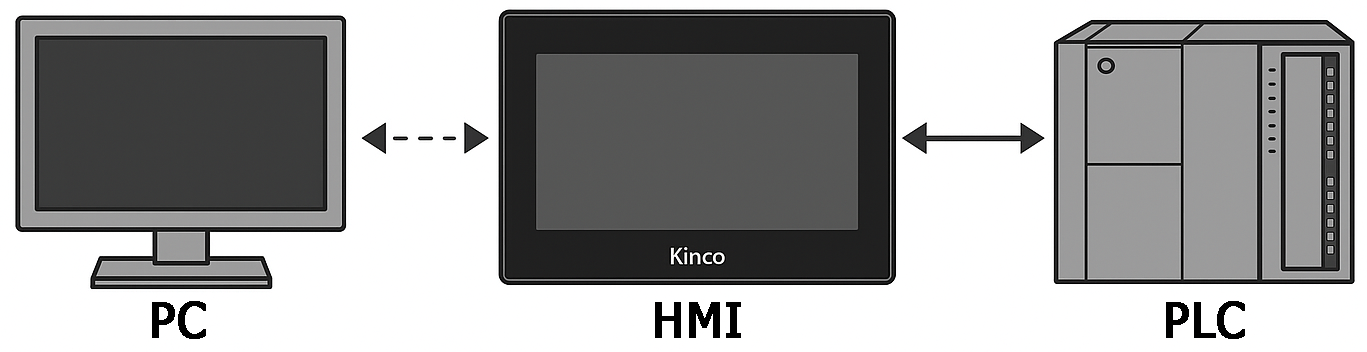

Human-Machine Interfaces (HMIs) serve as the vital link between operators and machines, enabling intuitive control, monitoring, and data acquisition. As your trusted supplier of automation solutions, Anaheim Automation offers a range of Kinco HMIs that combine robust performance with user-friendly programming. This article walks you through the step-by-step process to successfully integrate a Kinco HMI into your automated system.

Step 1: Choose the Right HMI for Your Application

Start by selecting an HMI model that meets the demands of your system. Key considerations include:

- Screen Size and Resolution: Display sizes ranging from 4.3" to 15"

- Communication Protocols: Ensure compatibility with your PLC, VFD, motor, and other components (e.g., Modbus RTU/TCP, Ethernet/IP)

- Environmental Ratings: Models like the KNC-HMI-G100E-LRF are IP65-rated for harsh environments

- I/O and Connectivity: Ethernet ports, serial ports (RS232/RS485), and USB ports

▶ Tip: Anaheim Automation's team can assist in matching one of our HMIs to your control system.

Step 2: Install Kinco DTools Software

Kinco HMIs are programmed using Kinco DTools, an intuitive software platform.

- Download the latest version from our website.

- Install the software on your engineering workstation (Windows-based PCs are recommended)/

▶ Tip: Ensure your PC has administrative privileges to avoid installation errors.

Step 3: Connect the HMI to Your PC

Use the appropriate connection method:

- USB Cable: For initial programming

- Ethernet Cable: For fast download and remote access

Depending on the HMI model, you may also need:

- Micro-USB to USB-A (for smaller HMIs)

- Standard Ethernet patch cable (Cat5e or better)

▶ Tip: Always power the HMI via its external power supply (typically 24VDC) during programming.

Step 4: Create Your Project in Kinco DTools

Launch Kinco DTools and follow these steps:

- Start a New Project: Select your HMI model from the project creation wizard.

- Set Communication Parameters:

- Choose the communication driver for your PLC or controller (e.g., Kinco, Modbus TCP Client, Allen Bradley, Mitsubishi, etc.)

- Configure the COM port settings (baud rate data bits, parity) to match the connected device.

- Design the Interface:

- Drag and drop graphical elements such as buttons, indicators, and trend graphs.

- Bind screen elements to specific PLC registers (e.g., memory addresses, input/output coils).

- Set Alarms and Logging (Optional):

- Configure alarm elements and data logging features if your application requires traceability.

▶ Tip: Use built-in templates for faster setup and consistent UI design.

Step 5: Communication

Before deploying to production:

- Use the Simulation Mode in DTools to verify basic functionality.

- Connect the HMI to your automation network (or directly to your PLC).

- Test each screen to ensure proper data exchange (read/write) between the HMI and the controller.

▶ Tip: If communication fails, double-check the IP addresses, COM port settings, and device IDs.

Step 6: Download and Deploy

Once tested:

- Download the project to the HMI via USB or Ethernet.

- Power cycle the HMI if necessary to initialize the application.

- Monitor startup logs on the HMI to ensure successful boot and communication.

▶ Tip: Keep a backup of your DTools project files for future edits.

Step 7: Final System Integration

Integrate the HMI into your system enclosure or control panel:

- Mount the HMI securely using the supplied gasket and clamps.

- Wire communication and power cables neatly to avoid EMI (electromagnetic interference).

- Label all connections for easy maintenance.

If desired, set up advanced features such as:

- Remote Access: Allow maintenance personnel to view and troubleshoot remotely.

- Data Logging and Cloud Reporting: Save data to USB, SD card, or send to an IoT platform.

▶ Tip: For outdoor or washdown environments, ensure gasket seals and enclosures meet IP ratings.

Integrating a Kinco HMI from Anaheim Automation into your automated system streamlines and enhances operator control and system visibility. By following these steps - from selection to final deployment - you can ensure reliable and professional setup.

Need more tips and tutorials for your HMI? Check out our HMI Playlist: