We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

ENC-ME-P12-236-220-12

| Interface | 12-Bit PWM |

|---|---|

| Bore | .236" |

| Shaft Length | 0.220" |

| Bolt Circle | 1.280" |

Product Information

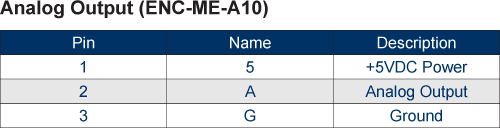

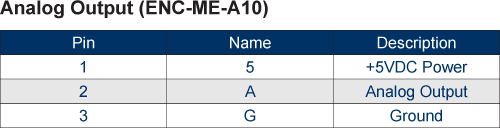

The ENC-ME Absolute Magnetic Kit Encoder equips the shaft with position information of over 360° of rotation with no stops or gaps. The ENC-ME is made to easily mount and dismount from an already existing shaft to provide digital feedback information. Analog or Pulse Width Modulated (PWM) digital outputs are available. With the Analog Output it provides an Analog voltage that is proportional to the absolute shaft position. ENC-ME with Analog is only available in the 10-Bit resolution. The PWM output is available in both 10-Bit and 12-Bit resolutions. When using the PWM output it will provide a pulse width duty cycle that is equivalent to the absolute shaft position. Both the 10-Bit and 12-Bit versions of encoders have the same accuracy; however, the 12-Bit version provides higher resolutions. There are three main components that make the ENC-ME: base, push-on magnetic hub, and encoder body. The base fits 0.750", 1.280" and 1.812" mounting bolt circles. The collet gripping hub does not require any tools and simply is pushed onto the existing shaft. It takes only a few seconds to attach the hub to the shaft. With the hub attached to the shaft it provides an easy and dependable way of securing the magnet to the shaft. Furthermore, the encoder body is placed over the magnetic hub and can be secured to any flat surface. With a simple connection process involving only 3-pins, the high retention snap in 1.25mm connector, that is pitch polarized, provides +5V for output and ground.

Note: When using the ENC-ME Absolute Magnetic Kit Encoder, the Mini Differential Encoder Cable ENC-CBL-CA-MIC3-SH-NC is required to work correctly.

- Fast, Easy Assembly and Disassembly

- Fits Shaft Diameters from 0.118" to 0.250"

- Mounts onto 0.750", 1.280", and 1.812" Bolt Circles

- ±0.025" Axial Shaft Play

- 10-Bit Analog Output - 2.6 kHz Sampling Rate

- 10-Bit PWM Output - 1024 CPR, 1 kHz

- 12-Bit PWM Output - 4096 CPR, 250 Hz

- Operating Temperature of -40° to +125°C

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)