We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

34A109E

| Bipolar RMS Current (A) | 3.4 |

|---|---|

| Bipolar RMS Voltage (V) | 2.6 |

| # of Lead Wires | 6 |

| Weight (lbs) | 3.35 |

| Motor Length (in) | 2.54 |

| Lead Time | Typ 45 Days |

Product Information

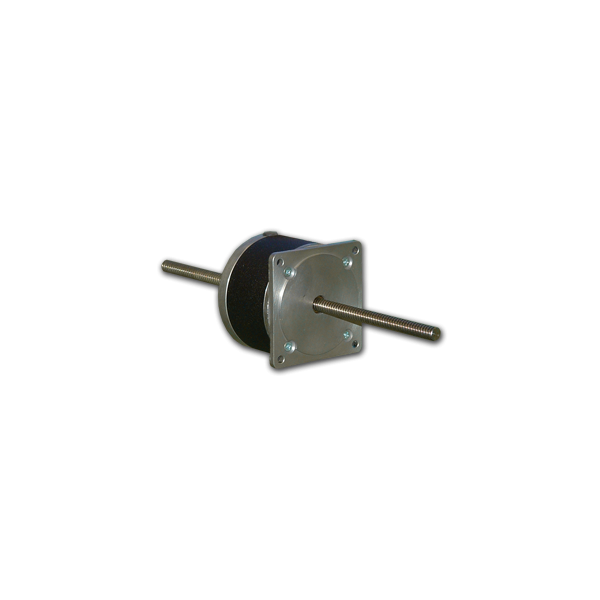

The 34A Series stepper motors offers many advantages to users over previous design choices. All of the lower cost digital attributes of a hybrid step motor are retained while the internal conversion to linear motion eliminates the need for other rotary- to-linear conversions such as belt and pulleys, racks and pinions, or external ball screws. Motion designs can be simplified, production costs lowered and product life enhanced. The 34A design captures a bronze acme nut internally such that each normal electrical step sequence results in the linear travel of a mating screw axially. Since the ends of the screw are free-floating, any length can be used; if the motor is fixed, the screw will travel, if the screw is fixed, the motor will travel. Normal open loop drivers can be used. Typical applications for the linear step motor actuator include X-Y tables, pick and place, medical instrumentation, valve adjustment, and test equipment. We can bring together many of the components required to make your application work the best.

For compatible stepper drivers, consider our popular BLD, MBC05641, MBC12101, and Driver Pack series.

- Step Motor With Internal Conversion to Linear Output

- Self Contained Package with Long Shielded Ball Bearings

- Available in a Wide Variety of Voltage and Inductance Ratings

- Can be Microstepped for Smoothness and Resolutions up to 2 x .000001

- Several Lead Screw Choices

.png)

.png)

.png)

.png)

.png)

.png)