We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Medical Devices and Life Science Solutions

For over 50 years, Anaheim Automation, Inc. has provided a wide variety of motion control products to OEM customers that serve the medical, pharmaceutical and life science industries. These applications include diagnostics, imaging, laboratory equipment, patient and surgical beds, personal mobility equipment, liquid pumps, medication dispensing, as well as the equipment needed for manufacturing, packaging, and labeling medical devices.

Our extensive experience with OEM customers in the medical/life science industries means we understand the important requirements of their end-products: quality, precision, repeatability, sizing consideration and footprint limitations, efficiency, quiet operation, and the ability to procure sample sizes for Research & Development projects. Anaheim Automation understands that the timeliness in response to technical questions and concerns in the R&D phase, and the ability to customize to an exact requirement, are critical to its life sciences customers.

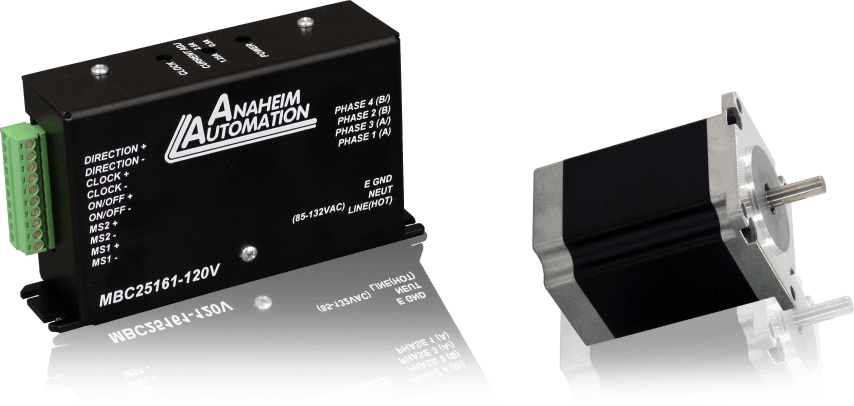

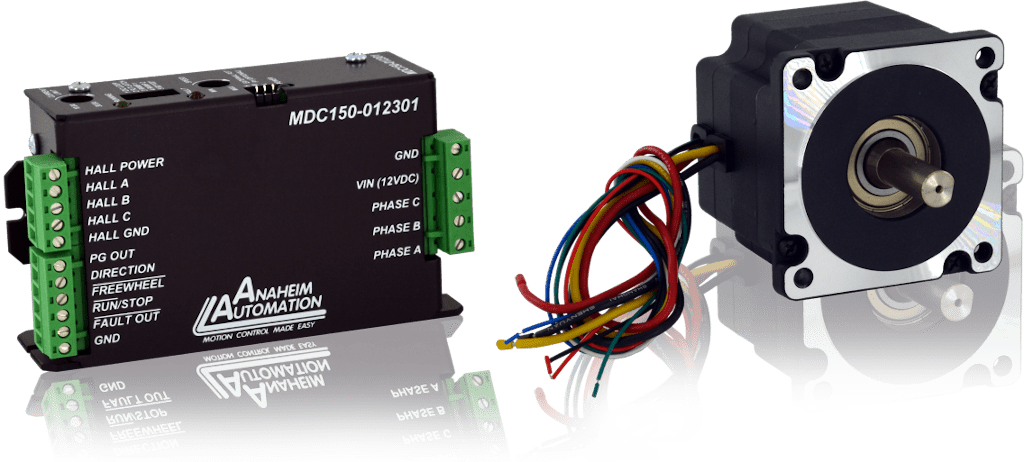

The most popular products for the Medical Devices / Life Sciences industry include Stepper Motors, Brushless DC (BLDC) Motors and Gearmotors, Integrated Motors/Drivers/Controllers, Linear Actuators, Brush DC Gearmotors, and Human Machine Interfaces (HMIs). Stepper and BLDC Motors are the most commonly used, and they are most often purchased with added Encoders and Cable/Connectors, integrated by Anaheim Automation as value-added services. We also provide Integrated Stepper and BLDC motors, which are combination motor and driver, or motor/driver/controller, integrated in one compact package.

Products for Medical Devices/Life Sciences Solutions

Stepper

Stepper motors, stepper gearmotors, stepper actuators, and stepper motors with integrated drivers/controllers are commonly used in medical applications such as fluid pumps (e.g. those used in transfusion, infusion, metering or dialysis) and imaging equipment. NEMA sizes 08 – 24 are the most popular Stepper Motors for these industries, though Anaheim Automation can also provide NEMA 34 and 42 stepper motors. Please review our series 08Y, 11Y, 14Y, 15Y, 17Y, 23Y and 24Y stepper motor series for specifications. For Integrated Stepper Motor/Drivers, see 17MD and 23MD series, and for Stepper Motors with integrated Drivers and Controllers, see 17MDSI and 23MDSI series.

Stepper Gearmotors are also very popular with our Medical Devices and Life Sciences customers, often being used in patient beds, patient transport, imaging machines, and automated lab equipment. Anaheim Automation's Stepper Gearmotor line offers either hybrid stepper motors, or permanent magnet (PM) stepper motors, with either a planetary or spur gearbox affixed, in one streamlined unit. The Stepper Gearmotor series most suitable for bio-med and life sciences applications include: 11YPG, 17YPG, 23YPG and 24YPG hybrid stepper gearmotors with planetary gearboxes, and the TSM and TGM series, which are PM stepper motors with spur gearboxes. Each Stepper Gearmotor series offers a wide range of gear ratios.

All Stepper series can be customized to include an encoder, and/or cable and connector, even at sample quantities. Stepper motors/actuators with encoders, for example, are especially popular in fluid pumps, as well as medical imaging equipment such as X-ray, CT, MRI, mammography, and bone density. Further customization – such as shaft modifications, special windings, or private-labeling – are also available, but may require an MOQ (Minimum Order Quantity).

Brushless DC

Our BLDC motor range is vast, ranging from the small BLU06 series (a 16mm round-bodied motor), to the powerful BLY34 series (NEMA 34 motors). Most popular for the medical/life science industries are the following BLDC Motor series: BLWR09, BLWR11, BLWR13, BLWR17, and BLWR23, which are round-bodied motors, and the BLY17 and BLWS23, which provide a square mounting flange.

As with Stepper Motors, the BLDC Motors used in the medical/life science industry are typically used with an encoder, which Anaheim Automation can mount for a complete assembly, or can be purchased separately. For example, brushless motors are often paired with encoders in medical centrifuge applications, such as blood analyzers. Brushless motors supply smooth, continuous, high-speed rotation, while an encoder provides valuable feedback information – e.g. speed, direction, distance – allowing for precise system control.

System designers who need the benefits of a brushless motor and speed controller for medical/life science applications may consider Integrated BLDC Motors (motor with a speed controller) to help streamline component selection, minimize footprint, and simplify installation. Popular Integrated Brushless Motors/Controllers for Bio-Med applications include the BLYxxMDC, BLY17MD, BLYxxMDA, BLWR23MD BLWS23MD series. All integrated BLDC motor series can be customized to include an encoder, and/or cable and connector, as well as other value-added services.

Our BLDC Gearmotors are also a popular choice for medical/life science applications, especially the BLWRPG09, BLWRPG11, BLWRPG17, and BLWRPG23 series, in which a brushless DC motor is integrated with a planetary gearbox, and each series offers a wide range of gear ratios. Brushless gearmotors are popular in personal mobility equipment, patient beds and exam tables, and many other medical applications thanks to their ability to deliver high torque density, smooth motion, and quiet operation.

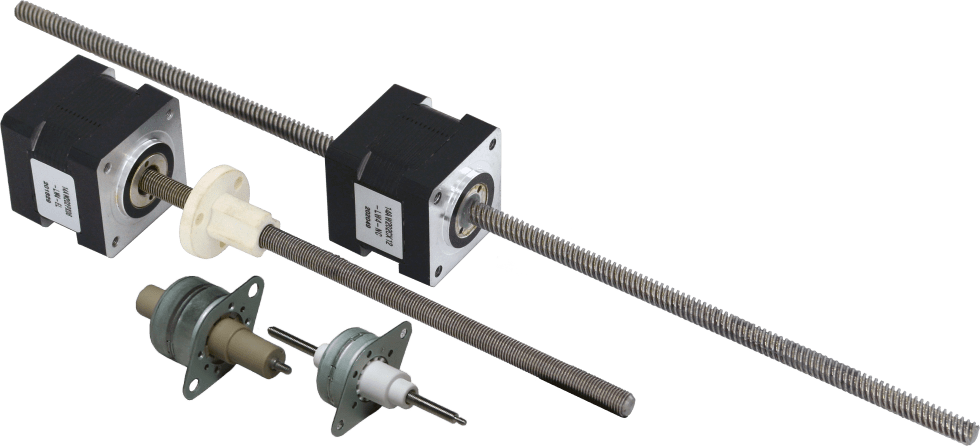

Linear Actuators

Linear Actuators are also very useful in medical/life science applications. While Anaheim Automation provides a large variety of linear actuators, the most popular linear actuators among our OEM bio-med customers are the Stepper and BLDC Linear Actuator types.

In the stepper linear actuator line, there are Hybrid Stepper and Permanent Magnet (PM) Non-Captive and Captive Linear Actuators. The most popular hybrid stepper linear actuators are the 08AW, 11AW, 14AW and 17AW series (the numbers correspond with the NEMA size), thanks to their small footprint, although NEMA 23 and NEMA 34 linear actuators are also available. Hybrid stepper motor actuators are very popular in medical metering and dosing pumps, as they deliver precision motion at high speeds in a compact package. For the PM stepper linear actuators, sometimes called "can stack stepper actuators" please review captive series or non-captive series.

For BLDC linear actuators, see BLAW17 and BLAW23 series. Our brushless motor linear actuators combine 24VDC brushless motors with external rolled ball screws to create the most robust and versatile linear positioning motor on the market. Standard models offer high torque density and precision positioning for R&D, and custom modifications are available for high volumes.

Also available in the linear actuator category, are Screw-Driven, Belt-Driven, and Rod-Style Linear Actuators, X-Y Tables/slides, as well as linear servos. We also offer a full line of Ball Screws and Linear Guides. These products are commonly used in desktop laboratory equipment, diagnostics, and medical imaging systems such as CT Scanners, MRI Scanners, and PET Scanners used in orthopedics, neurology, cardiology, oncology, neurology, and trauma care.

HMI

Another popular product used in medical/life science applications is the Human Machine Interface (HMI), commonly referred to as Industrial Touch Screens. Anaheim Automation's broad line of HMIs is one of the most cost-effective options in the industry. Our industrial touch screens, available in display sizes 4.3" to 15", offer a user-friendly graphical interface through which customers can easily control their system from a centralized location, including remotely.

HMIs can support even the most complex of applications, with multiple screens and several routines running simultaneously, ideal for the requirements frequently found in the medical/life sciences industries. HMI touch screens are extremely versatile, and may be found in many types of applications across the Medical/Life Sciences industries. Common use-cases include diagnostics, dispensing, pill counters, patient records, laboratory equipment, and medical device manufacturing. The communication protocol on all of our HMIs is customizable to work with multiple PLC brands, including Allen Bradley, Siemens, Schneider Electric, BACnet and many others, making it easy to integrate our HMI into virtually any system while enjoying substantial cost savings. Our HMI/PLC combo units may be even an even more economical solution, while also reducing development time and footprint.

Common Applications

Personal Mobility Equipment

Personal Mobility Equipment – such as motorized wheelchairs, motorized scooters, or stair lifts – requires robust components with long lifespan. As with all medical applications, smooth and quiet operation are of the utmost importance, but mobility equipment also demands high torque output, particularly high starting torque.

Products for Personal Mobility Equipment

Brushless DC Motors

Low-maintenance BLDC motors deliver high torque density and quiet, smooth operation, ideal for robust medical applications like personal mobility equipment.

Brushless DC Gearmotors

BLDC gearmotors offer the same quiet, smooth operation as BLDC motors, but the integrated gearbox provides higher torque than a motor alone.

Gearboxes

Gearboxes provide additional torque while maintaining the quiet and smooth operation required for medical equipment.

Encoders

Motors used in personal mobility equipment are often paired with encoders, which provide feedback information for a greater degree of system control.

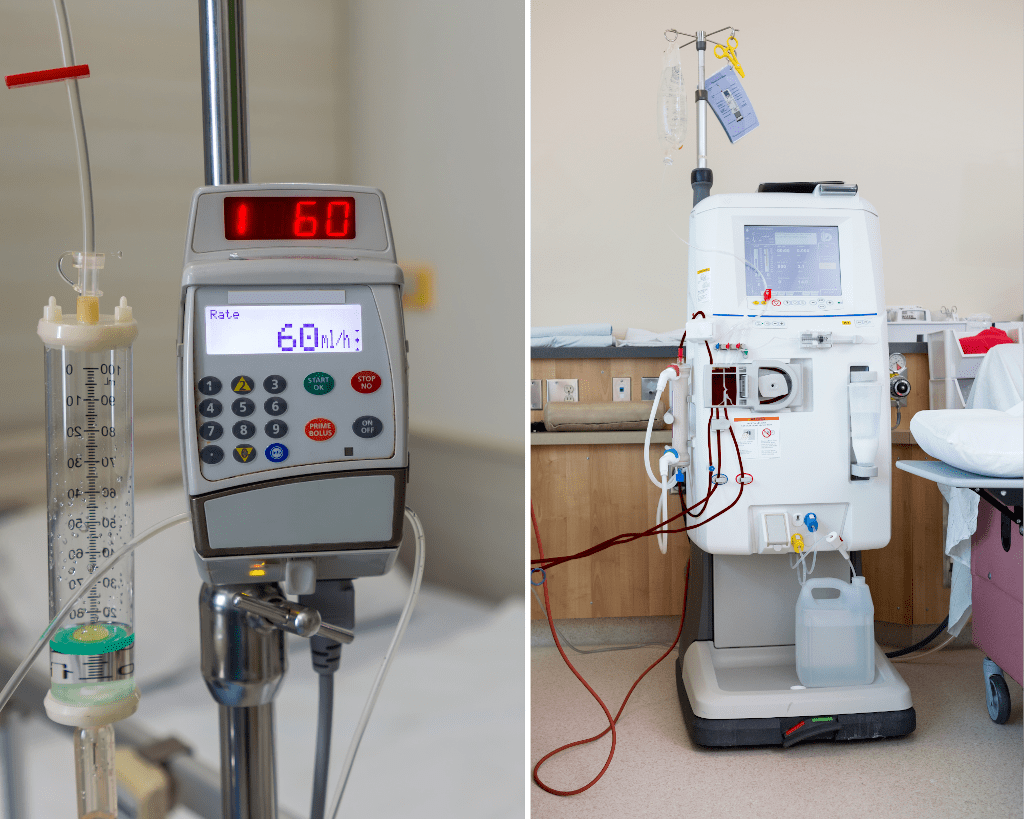

Fluid Pumps

Medical fluid pumps – such as those used in transfusion, infusion, dialysis, or metering pumps – must reliably deliver fluids in a highly controlled manner. Fluid pump applications require components that are precise, reliable, and accurate, offering high levels of repeatability. Compact size, low noise, and high torque density are also common requirements.

Products for Fluid Pumps

Brushless DC Motors

Brushless motors deliver the high torque density, smooth motion, and precise speed control needed for medical fluid pumps. Brushless motors are particularly popular in these applications due to their low noise operation.

Stepper Motors

Stepper motors are ideal for fluid pump applications thanks to their ability to deliver precise positioning and high repeatability without requiring feedback, based on predetermined input.

Stepper Actuators

Stepper motor linear actuators are popular in medical fluid pumps, offering the same benefits as stepper motors, plus linear positioning, in a compact, integrated package.

Encoders

Motors with encoders are very popular in medical fluid pump applications, as encoder feedback allows for more precise position and speed control.

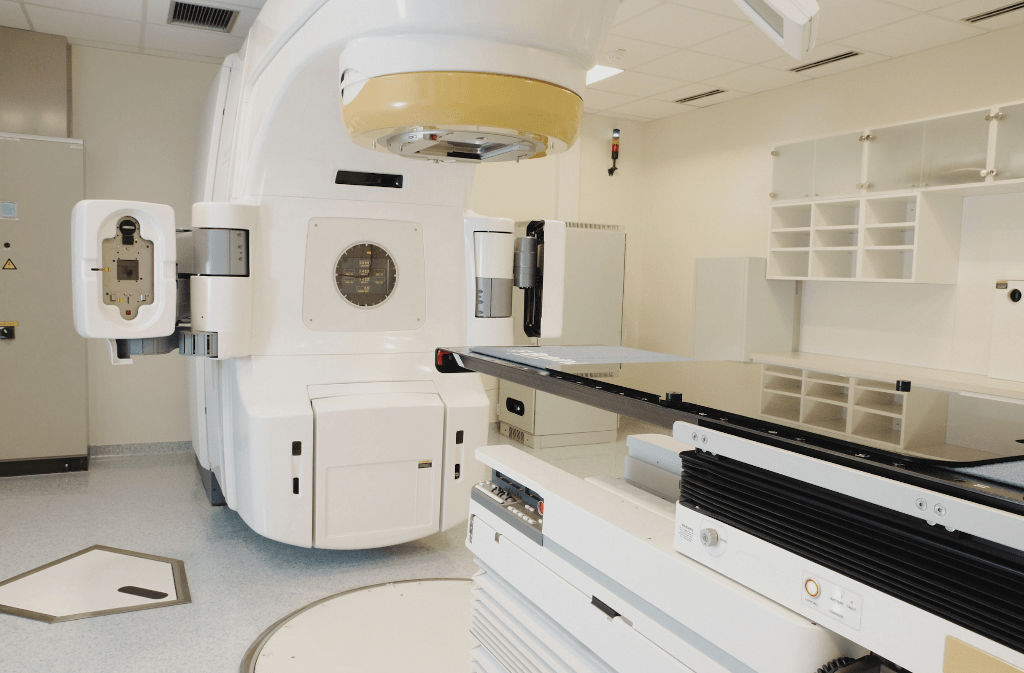

Imaging Equipment

In medical imaging equipment, such as X-ray, CT, MRI, bone density, or mammography, patient comfort is a top concern. Medical imaging applications require components that are accurate and reliable while delivering smooth motion and quiet operation.

Products for Imaging Equipment

Brushless DC Motors

Small BLDC motors (those in the 16mm to 57mm/NEMA 23 range) are very popular in medical imaging applications, especially paired with encoders. Brushless motors are smooth, quiet, reliable, and long-lasting. Adding an encoder for speed, direction, and position feedback allows a greater degree of system control.

Stepper Motors

Small stepper motors, such as sizes NEMA 08-24, are ideal for imaging equipment because they offer precise positioning based on predetermined input. Though steppers are open-loop accurate, they are often paired with encoders in medical imaging equipment applications, for added system feedback.

Linear Components

Linear components are often used in medical imaging equipment where linear travel is required. Whether a bone density scanner, in which the imaging device travels along the patient's body, or an MRI, in which the patient is moved through the imaging device, ball screws and linear guides are popular in these applications.

Complete Motion Systems

Stepper, Brushless DC, and Servo systems – complete with motor and driver/controller, cables and connectors, encoders providing feedback, linear components, and other accessories – provide a total solution for complex medical imaging equipment applications.

Patient Beds

In the medical industry, patient beds – such as hospital beds and exam tables – are often automated with the ability to raise and lower, shift forward and back, and tilt. Automated patient beds make examination easier and prevent injury to patients and caregivers. With the focus on safety and comfort, patient beds require components that offer low-noise operation while providing smooth and powerful motion.

Products for Patient Beds

BLDC Motors and Speed Controllers

Offering a high torque density and the ability to operate smoothly and quietly – brushless motors are ideal for applications like patient beds and exam tables, in which a patient needs to be positioned safely and comfortably. Patient bed applications require systems that are robust, reliable, and unobtrusive. Low-maintenance BLDC motor systems are an ideal solution for these requirements.

BLDC Gearmotors

BLDC gearmotors may be suitable in applications requiring higher torque than a standard brushless motor. Gearmotors integrate a motor and gearbox into one streamlined unit, offering all the benefits of a brushless motor with added torque output.

Integrated BLDC Motors with Controllers

Brushless DC Motors with Integrated Speed Controllers offer a 2-in-1 solution. In applications where space is especially limited, integrated units offer reduced footprint, while simplifying component selection and installation.

Encoders

Encoders provide valuable system feedback, enabling more precise system control. Encoders of all types are often used in patient bed and exam table applications, especially alongside BLDC motors.