We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Top 3 Motor Technologies for Compact Machines: Stepper vs Servo vs BLDC

Top 3 Motor Technologies for Compact Machines: Stepper vs Servo vs BLDC

When developing compact machines, engineers must make crucial decisions around motion control. Stepper, Servo, and Brushless DC (BLDC) motors, drivers, and controllers each offer unique traits that can significantly impact system performance, cost, complexity, size, and integration paths. Selecting the best fit involves weighing precision, speed, torque, footprint, and control complexity. At Anaheim Automation, we offer a full range of motion control products to suit each technology—and help OEMs match the right motor to the job.

In this article, we’ll see how each type stacks up by going over the pros, cons, and ideal applications. We'll also provide product recommendations from our catalog that align with compact automation applications.

The Big Picture: Motion Requirements First

Before selecting a motor for your project, ask yourself the following:

- How much torque is needed across the operating speed range?

- Is position accuracy and repeatability critical?

- Will the system require closed-loop feedback?

- Are cost, power efficiency, or noise priorities?

- What is the machine's size constraint?

With these factors in mind, let's break down each motor type.

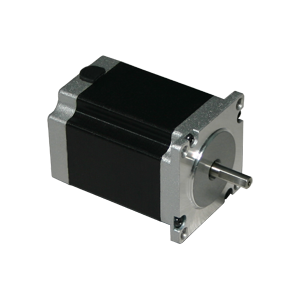

Stepper Motors and Drivers: Cost-Effective Reliability

Stepper motors excel in applications where precision positioning and cost-effectiveness are key. They operate in discrete steps, making them ideal for systems that operate at low speeds and don't require feedback.

| Advantages | Limitations | Best For | Applications |

|

|

|

|

Recommended Anaheim Automation Products and Solutions

- 23Y Series Stepper Motor: NEMA 23 square frame; perfect for compact automated machinery such as label applicators or small conveyors.

- MBC25081TB Stepper Driver: Made in U.S.A.; compact microstepping driver, 12-24VDC, with adjustable current control and detachable terminal blocks.

Example Use Case

An OEM designing a compact deskto9p pick-and-place system coulld use a 23Y206S-LW8 stepper motor with the MBC25081TB driver for the XY axis - delivering 1.8°, 0.9°, 0.45°, or 0.225° step angle and solid repeatability without the requiring an encoder.

Servo Motors and Drives: Compact Power and Precision

Servo motors use closed-loop feedback (typically via an encoder) to maintain consistent and accurate position, speed, and torque. This allows them to excel in high-performance applications requiring fast acceleration, high RPMs, and continuous torque over a range.

| Advantages | Limitations | Best For | Applications |

|

|

|

|

Recommended Anaheim Automation Products and Solutions

- iSMK Integrated Servo Motors: All-in-one servo motor, encoder, and drive systems. This provides reduced wiring, compact footprint/housing, and simplified installation.

- iWMC Integrated Servo Wheels: Integrated wheel + servo motor + drive assemblies designed for mobile platforms, AGVs, and robotic systems where compactness and dynamic motion control are essential.

Example Use Case

A compact automated camera panning and dolly system requires high-precision movement with minimal cabling and a small footprint. An iSMK60-020 series integrated servo motor provides closed-loop control and smooth motion without the need for an external drive. For mobile base motion, an iWMC10409 series wheel module offers integrated torque control and easy CANopen or RS485 communication, allowing precise multi-axis coordination in a lightweight, embedded design.

Read this article for additional information on our iSMK and iWMC integrated servo solutions.

Brushless DC Motors and Controllers: Quiet and Efficient Powerhouses

BLDC motors offer high efficiency, reliability, and quiet operation, making them an ideal middle ground between the simplicity of a stepper and the superior control of a servo.

| Advantages | Limitations | Best For | Applications |

|

|

|

|

Recommended Anaheim Automation Products and Solutions

- BLWR111S-24V-10000 BLDC Motors: Compact BLDC motors that offer strong torque in a small frame size (comparable to NEMA 11); perfect for laboratory testing devices or smart appliances.

- MDC100-050101 BLDC Speed Controllers: Made in the U.S.A.; brushless DC speed controller drives motors at currents of up to 10A (peak) and 50V. Using Hall sensor feedback, constant velocity mode can be selected.

Example Use Case

A biomedical device OEM is developing a compact benchtop centrifuge designed for rapid sample separation in lab and clinical environments. The unit must maintain a precise, stable speed, operate quietly for use in shared spaces, and remain maintenance-free for long-term reliability. The BLWR111S-24V-10000 motor, driven by the MDC100-050101 controller, can provide the necessary torque, and - because the motor lacks internal brushes - it can do so quietly.

Comparison Table

| Feature | Stepper | Servo | Brushless DC |

| Control Type | Open-loop (typically) | Closed-loop | Sensor-based (semi-closed) |

| Position Accuracy | Moderate - High | High | Medium |

| Speed Range | Low - Medium | Medium - High | Medium - High |

| Torque at Speed | Drops at higher RPMs | Maintains at speed | Good across RPM range |

| Cost Level | $$ | $$$ | $$ |

| Complexity | Low | High | Medium |

| Typical Size Range |

0.8" - 4.2" diameter (NEMA 08 - NEMA 42) |

40mm - 180mm diameter |

0.3" - 3.4" diameter (NEMA 09 - NEMA 34) |

Choosing the right motor type for your compact machine application begins with understanding your requirements, including load profile, precision level required, available space, control architecture, and budget constraints. At Anaheim Automation, we provide motion control and automation solutions to help our OEM customers bring compact, high-performance machines to market quickly and reliably.