We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Food and Beverage

The food and beverage manufacturing industry encompasses a wide range of processes, including harvesting, production, packaging, distribution, and retailing. The industry is a major contributor to the economy and plays an important role in providing safe and nutritious food and beverages to consumers. Stringent federal, state, and local regulations, as well as industry best practices, apply to every step in the food and beverage processing-to-consumer pipeline. Companies in the industry must also comply with labeling and nutritional requirements, as well as packaging and shipping regulations.

The industry is constantly evolving, with new technologies and processes being developed to improve efficiency, safety, and quality. As consumer tastes and preferences shift, technology used in the industry must keep up with changing trends and demands. Automated equipment in the food and beverage industry helps to increase productivity, reduce overall costs, and improve efficiency. Nearly any aspect of the manufacturing process can be automated, from order processing, to production, to packaging and distribution, helping to streamline processes and improve end-product quality, and expedite time to market. Automation can optimize production schedules, control inventory levels, and reduce human errors and system downtime. Automation can also help to ensure compliance with food safety regulations.

For over 50 years, Anaheim Automation, Inc. has been dedicated to providing high-quality components to our OEM customers in the food and beverage industry. Applications include raw material and bulk ingredient handling, batch control systems, mixing/blending/coating equipment, packaging/wrapping/palletizing machines, and bottling/filling systems among many others. Some of our most popular products for these applications include Brush DC, Brushless DC, Servo, and Stepper motors, controllers, and drivers, as well as Encoders, HMIs, VFDs, and Linear Guide assemblies.

Products for Food and Beverage

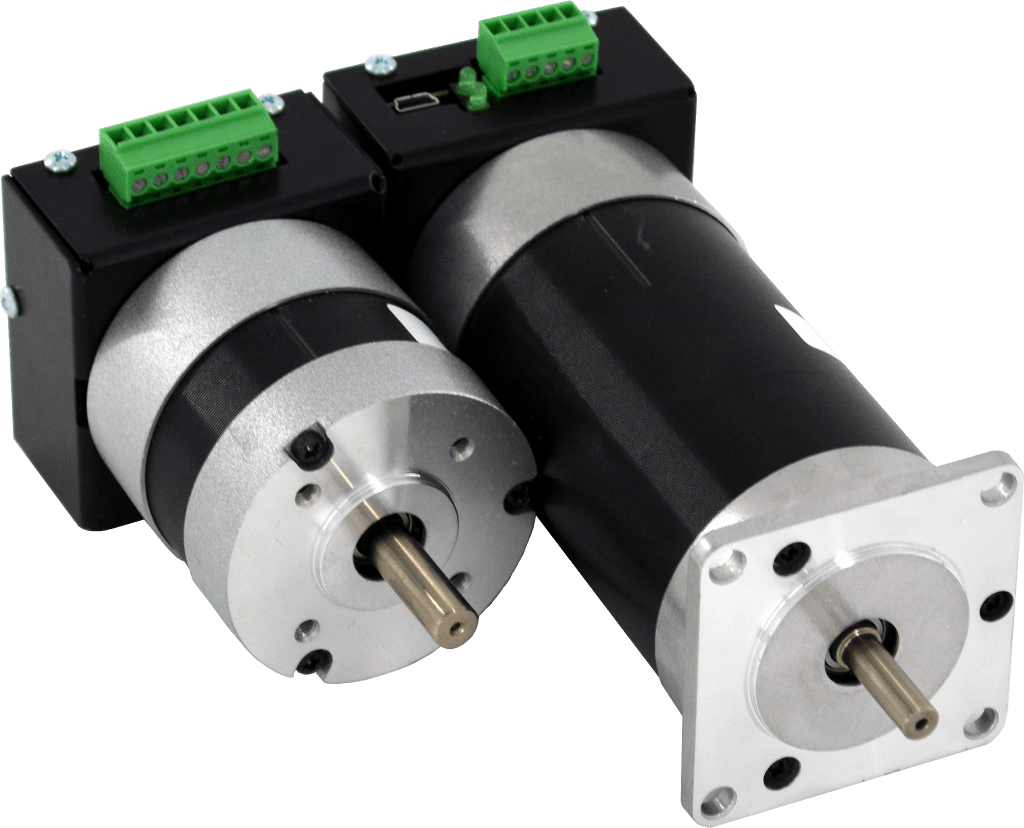

Brushless DC

Our broad family of BLDC products is ideal for applications in the food and beverage industry, with motors ranging from the 16mm frame size BLU06 series to the robust NEMA34 BLY34 series. Some of the most popular choices include the BLWR17 and BLWR23 series, as well as BLY17, BLWS23, and BLWS24 series. The addition of an encoder to these motors provides feedback data and improves system control. Anaheim Automation can mount encoders for a complete assembly, or encoders can be purchased individually.

For applications which require lower speeds or higher torque, our BLDC Gearmotors are an excellent option. These brushless motors with integrated planetary or spur gearboxes are offered in a wide range of frame sizes and gear ratios to suit the exact requirements of nearly any project. Brushless gearmotors are especially useful in sorting, stacking, cartoning, and other packaging applications thanks to their smooth motion and high torque density.

Our Integrated Brushless Motors with Speed Controllers provide users with all of the benefits of a complete BLDC system in one streamlined package. These integrated units simplify component selection, reduce footprint, and allow for fast and easy installation. Many in the food and beverage industry prefer the BLY17MDA, BLY17MDC, BLWS23MDA, and BLY34MDA series integrated BLDC motors due to their compact size and because they are matched components, which makes selection fast and easy. All of our integrated BLDC motors can be customized to include an encoder, and/or cable and connector, among other value-added services. Full customization for all of our brushless components - including shaft modifications, special windings, private-labeling, and more - is also available with a Minimum Order Quantity (MOQ).

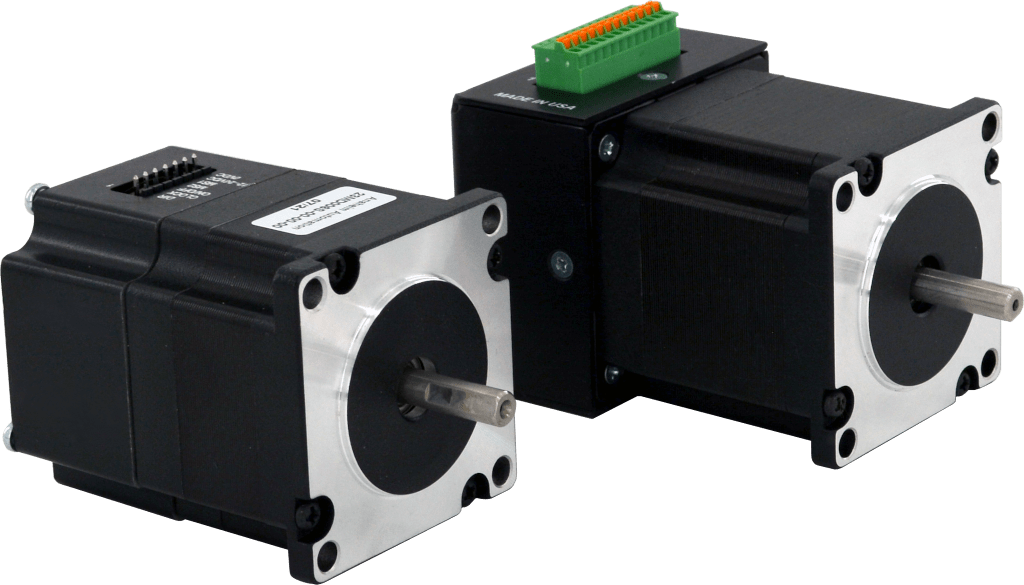

Stepper

Stepper products including motors, drivers, motors with integrated drivers/controllers, gearmotors, and linear actuators are often used in the food and beverage industry, especially in applications such as positioning for a cut/slice, cut-to-length, pack-and-place, bottle alignment, labeling bottles, cans, jars, boxes, etc. Anaheim Automation's broad line of Stepper Motors in NEMA sizes ranging from 08 to 42 are cost-effective and highly reliable, requiring little to no maintenance for the duration of their operation life. Steppers are especially ideal for food and beverage applications, with the NEMA 23 and NEMA 34 series being the most popular.

For applications requiring IP65 Rated Stepper Motors, Anaheim Automation offers NEMA 17 to NEMA 42 models, including the 17L65, 23Y65, 34Y65, and 42Y65 series. Contact Anaheim Automation directly to discuss applications that require wash-down or food-grade motors.

For customers who are looking for convenient component selection and installation, our Integrated Stepper Motors/Drivers are available in NEMA 17, NEMA 23 and NEMA 34 frame sizes. See the 17MD, 23MD, 17MDSI, 23MDSI, 34MD, and 34MDSI series for detailed product information.

Stepper Gearmotors are used in similar applications, but where extra torque and lower speeds are required. Anaheim Automation's stepper gearmotors are available in hybrid or permanent magnet (PM) styles, with either a planetary or spur gearbox integrated with the motor. The stepper gearmotors most commonly used in the food and beverage industry are the 17YPG and 23YPG series, which have integrated planetary gearboxes, and the 23YSG and 34YSG series, which have spur gearboxes integrated. Each stepper gearmotor series provides a wide range of gear ratios.

All of our stepper products can be customized to include a brake, encoder, and/or cable and connector, even at small quantities. Full customization - such as shaft modifications, custom windings, private labeling, voltage matching, etc. - are also available with a Minimum Order Quantity (MOQ).

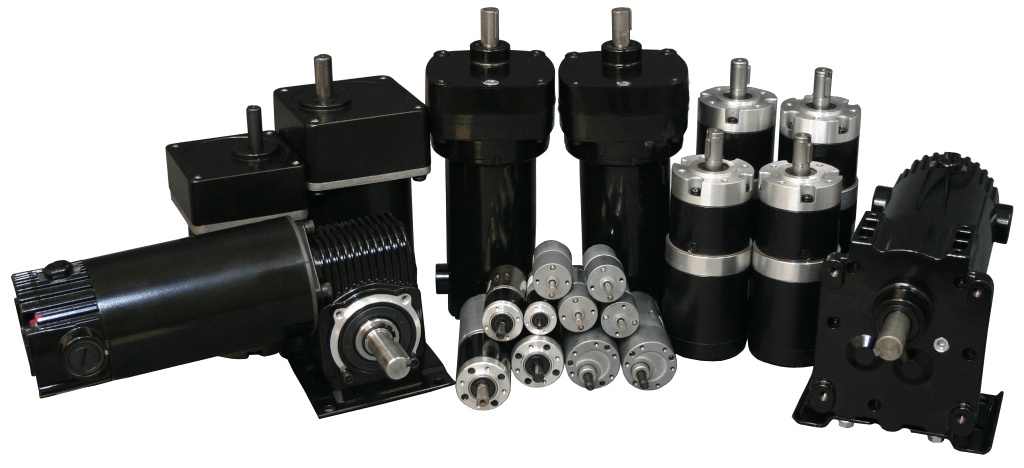

Brush DC

Brush DC Motors and Gearmotors are an economical choice for a wide variety of applications in the food and beverage industry. For example, brushed motors are often used in conveyors, mixers, and pumps due to their high torque output. They are also relatively simple to control, and can be easily integrated into automated systems. Anaheim Automation's line of standard Face Mount Brush DC Motors and Flange Mount Brush DC Motors are available in frame sizes from 20mm to 95mm and are able to deliver between 0.08 and 113.28 oz-in of torque, and are fully reversible. Our 56C Frame line models can provide from 288 to 576 oz-in and are rated for Class F insulation, meaning they are able to handle temperatures up to 221 degrees Fahrenheit at full load capacity.

Our Brush DC Gearmotors offer high precision at an affordable price. They are available in a variety of types, including Permanent Magnet DC (PMDC) Motors with Planetary Gearboxes, PMDC Motors with Spur Gearboxes, High-Torque PMDC Motors with Spur Gearboxes, and PMDC Motors with Worm Gearboxes. These gearmotors are available in sizes from 20mm to 95mm and can produce torque up to 576 oz-in with a wide range of gear ratios to choose from.

All of our brushed DC motors can be customized to optimize maximum speed, torque, and voltage. Modified cabling, wiring, connectors, and/or shafts are also available. Custom orders may require a Minimum Order Quantity (MOQ).

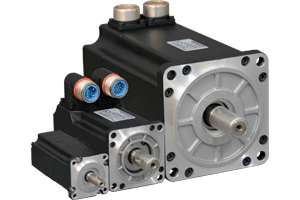

Servo

Anaheim Automation's robust Servo Motors are available in frame sizes from 40mm to 180mm, with power ratings ranging from 50W - 4000W in a variety of input voltages, and speeds up to 3000rpm. Their high torque output and ability to control the movement of multiple processes simultaneously make these motors ideal for applications in the food and beverage industry. They are often used to provide motion for conveyor belts, extruders, robotic arms, and more.

Our Servo Drives are excellent for position, speed, and torque control, combining versatility and functionality for high startup torque and precise motion control. They are compatible with our servo motors and are available in power ratings from 50W - 100W to 1,200W - 1500W with multiple VDC and VAC voltage options and I/O signals. Communication protocols include MODBUS, RS485, CANopen, and EtherCAT (model dependent).

Also available are our all-in-one matched Servo System packages, which consist of a motor, a matched drive, and cables to shorten component selection time and ensure compatibility. For users with applications where space is a concern, we also offer Servo Motors with Integrated Drives. These convenient combination units provide all the power of our standard models in frame sizes of 60mm or 80mm.

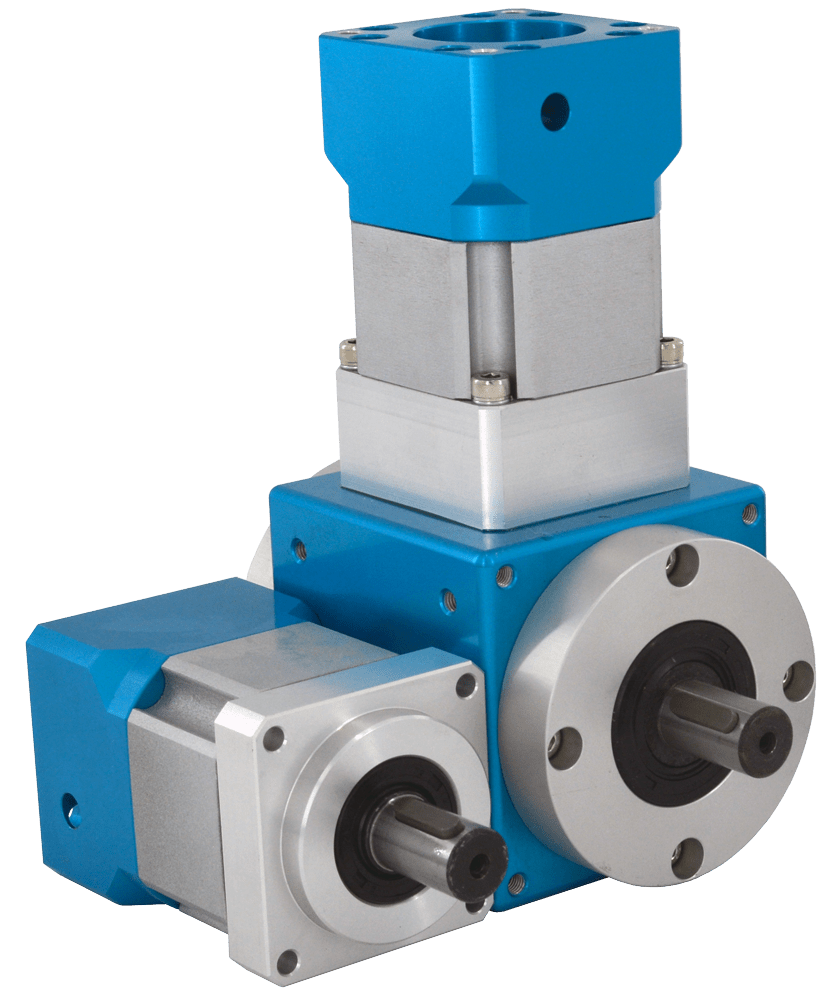

Planetary Gearboxes

Anaheim Automation carries a variety of Planetary Gearboxes in different styles, including Economy, High-Precision, Right-Angle, and Rotating Output Flange. Models are available in frame sizes from 40mm to 160mm and are compatible with most Anaheim Automation stepper, servo, or BLDC motors in frame sizes ranging from NEMA 17 to NEMA 42, as well as motors with C-Face mounting. Customers can also request custom mounting flange designs to match their gearbox to a motor from a different manufacturer. A minimum order quantity (MOQ) may apply.

Depending upon the specific unit, output torque can reach up to 11,329 in-lbs and backlash can be as low as 1 arc-min. Available gear ratios range from 3:1 up to 1,000:1, with maximum input speeds up to 18,000.

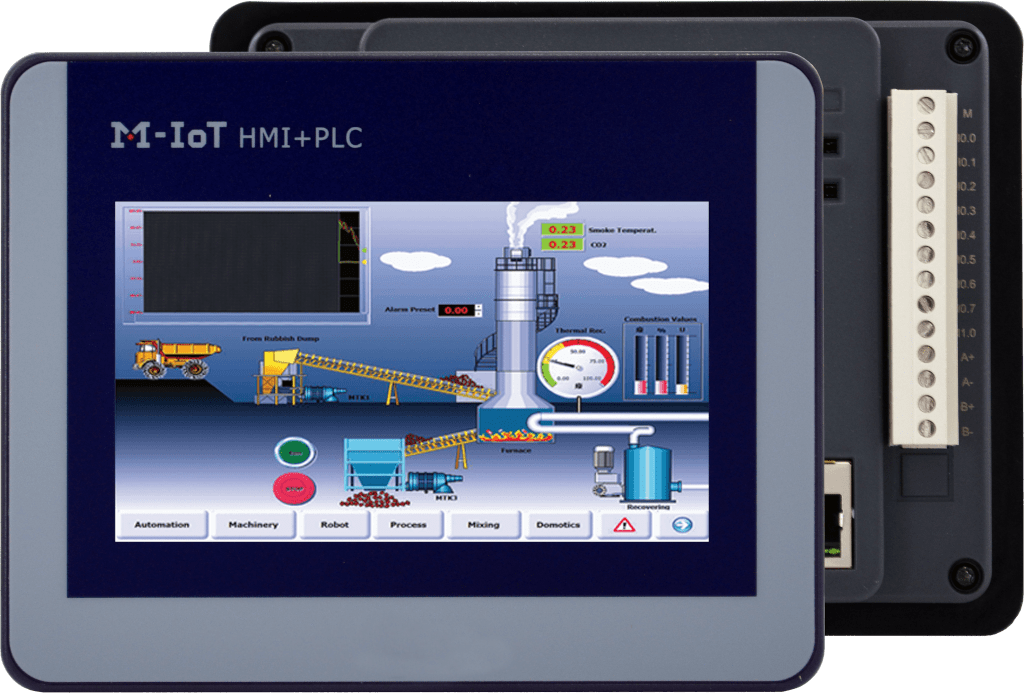

HMIs

Human Machine Interfaces (HMIs) - also referred to as Industrial Touch Screens - are also commonly used in food and beverage applications. Anaheim Automation carries a wide array of cost-effective HMIs available in screen sizes from 4.3" to 15". Our HMIs provide a user-friendly graphical interface that enables customers to easily monitor and control their system from a single centralized location. Remote monitoring and control are also possible, allowing operators to access the terminal from a distance.

HMIs are able to support high-capacity, complex functions, running multiple customizable screens and several routines simultaneously. The convenience and functionality provided by digitizing a control system with an HMI are invaluable. Because the communication protocol of our HMIs can be customized to work with multiple PLC brands, such as Allen Bradley, Siemens, Schneider Electric, and many others, integrating our HMIs into nearly any system is a simple, hassle-free process. In the food and beverage industry, HMIs are often used in applications requiring process control, temperature control, speed control, alignments, counting, etc.

For those who require a PLC as well as an HMI, consider our HMI/PLC combo units. These HMIs have an integrated PLC attached for unmatched convenience and operating power. The 4.3" KNC-HMI-MK043E-20DT and the 7" KNC-HMI-MK070E-33DT feature the same 256K color touch screen as our other HMIs, as well as all the special I/O and programming functions of a PLC in one sleek design.

VFDs

Anaheim Automation's rugged, low-maintenance VFDs (Variable Frequency Drives) provide high-performance, high-efficiency motor control by varying the frequency and voltage of the power supply. Our VFDs are compatible with most AC motors and are great for normal duty and soft-start applications and can help to optimize performance, reduce energy consumption, and minimize wear and tear on system components. They are equipped with a variety of valuable features, including built-in PID control, auto torque boost, auto slip compensation, momentary power loss restarts, flying starts, auto-acceleration/deceleration, and sensorless vector control.

Available in 120V single-phase, 240V single-phase, and 240V three-phase options, our VFDs are compatible with AC motors rated for 0.25 to 30HP. Standard communication protocols include Modbus and RS485. These units are ideal for a wide range of applications. For example, VFDs can be used to adjust the speed of a mixer to ensure consistent blending of ingredients, or to control the speed of a conveyor to prevent damage to fragile products.

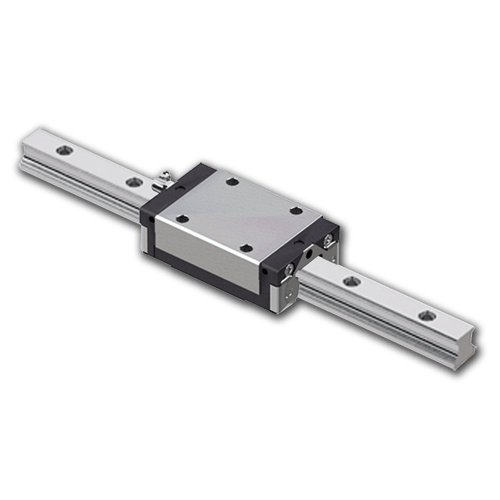

Linear Guides

Linear Guides, also known as "linear bearings and rails" or "linear guideways," are rail and block/carriage systems which support the linear motion of a given application. They ensure the accurate movement of products and increase efficiency. Anaheim Automation's rugged linear guides deliver accuracy and rigidity with low friction and zero vibration. Linear guides are an excellent option for conveyor systems, filling machines, and in sorting and packaging applications.

We offer a variety of bearing block options, with multiple preloads, end-seals, flanges, heights, and widths to choose from. Dynamic loads range from 0.2-0.3kN to 273.6kN (model dependent), and static loads range from 0.3-0.6kN to 419.0kN (model dependent). Standard rails are available in both stocked pre-cut lengths, as well as custom-cut lengths, with maximum lengths from 100mm to 4,000mm depending on the rail width. These linear guides come in rail sizes from 15mm to 65mm in width. In addition to our standard rails and blocks, which are sold separately, we also offer a range of miniature linear guide assemblies sold as complete units. Mini-guide assemblies are available in rail widths from 3mm to 15mm, with maximum rail lengths from 300mm to 1000mm (model dependent). For custom lengths, please allow 2-3 business days for processing.

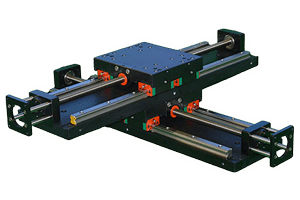

Linear Actuators

Linear Actuators are also often used in the food and beverage industry for various applications, including conveying systems, sorting and packaging machines, and others. They are primarily used to control the movement of different components. Anaheim Automation carries a wide range of linear actuators.

Our Screw-Driven actuators – sometimes known as Linear Stages or Positioning Tables – are capable of bearing dynamic loads up to 6,700 lbs, with speeds up to 1,500 mm/sec. Ball screw and Acme screw models are available, with stroke lengths from 100 to 1,240 inches. Screw-driven linear actuators are ideal for applications with heavy loads that still need to operate at high speeds, with high inertial loads. Screw actuators are also used in slow-moving point-to-point applications. Our LS100 tables are a popular choice, available in X and XY configurations with 6, 12, or 18 inch travel options.

Belt-Driven linear actuators are better suited for light load applications run at high speeds with low inertial loads. Anaheim Automation belt actuators are suited for dynamic loads up to 200 lbs, with travel speeds up to 118.1 in/sec. LB250 series actuators are compatible with any NEMA 23 motor, 60mm inline gearbox, or 60mm frame servo motor and are available with stroke lengths from 12 to 48 inches with a belt pitch of 1/5.

Some of the most popular linear actuators among OEM users are our stepper and brushless DC designs. In our line of Stepper Linear Actuators, options include Hybrid Non-Captive and External Linear designs, as well as Permanent Magnet (PM) Captive and PM Non-Captive models. Hybrid stepper actuator designs are available in frame sizes from NEMA 08 to NEMA 34 and are ideal for delivering precise motion at high speeds. Anaheim Automation BLDC Linear Actuators include the BLAW17 and BLAW23 series, both of which consist of a 24VDC brushless motor and an external rolled ball screw.

Also available are our leadscrew-driven LRM series Rod-Style Actuators, available in stroke lengths of 6 or 12 inches, and ideal for lifting or thrusting applications with space limitations.

Common Applications

Container Loaders

Container Loaders – Container loading machines are designed to load various products into bags, pouches, or other containers, eliminating the need for repetitive manual labor. These machines can quickly and accurately fill containers with food products, such as grains and powders, at high speeds. They are designed to handle a wide range of container sizes and materials, and can be easily integrated into existing packaging lines. Automated loaders also help to minimize product waste and ensure consistent filling levels, resulting in a more reliable and cost-effective packaging process.

Products for Bag Loaders

Stepper Motors

Stepper motors are often used in container loaders due to their precise incremental movements. These motors can accurately position loading arms, ensuring that items are loaded into the container safely and efficiently. Steppers can also be used to securely move the package down the production line, minimizing the risk of damage to containers and products.

BLDC Motors

Due to their high efficiency, reliability, and smooth movement, brushless motors are an excellent choice for use in container loaders. These motors can be used to power conveyor belts, lifting mechanisms, and other components of the loader. Additionally, BLDC motors are easily integrated into electronic control systems, allowing for precise automated control of the loading process.

HMIs

Human machine interfaces allow operators to interact with the loader and monitor its performance, displaying critical information such as container status, weight, and location. Operators can use the HMI to start, stop, and/or adjust the machine as needed. HMIs also provide alerts and warnings if any issues arise during operation, such as a container being out of place or over/underweight. This allows operators to respond to issues quickly, decreasing system downtime.

Vacuum Sealers

Vacuum Sealers – Automated vacuum sealing machines are used in the packaging of food items to preserve product freshness and quality, and/or to prepare items for shipment. They work by removing air from a plastic pouches or container and then sealing it, ensuring that no air can get back inside to protect against bacteria, freezer burn, and more. These machines are highly efficient and can handle large volumes, increasing productivity and saving time and labor costs, making them ideal for industrial use.

Products for Vacuum Sealers

Brush DC

Brushed motors provide high torque and reliable performance, making them ideal for driving the pump that creates the vacuum pressure for removing air and sealing containers. Additionally, their compact size allows them to be used in the confined spaces typical in vacuum sealers.

Linear Actuators

Linear actuators are commonly used in vacuum sealing machines to control the movement of the sealing arm that compresses the packaging material to create an airtight seal. These actuators are responsible for precise and consistent movement, ensuring that the seal is tight and reliable. They also provide a high level of control and adjustability, allowing for customization of the sealing process to suit different types of packaging materials and products.

Planetary Gearboxes

Planetary gearboxes are often used in vacuum sealing machines to achieve greater torque and speed control, resulting in a more efficient and effective sealing process. Additionally, the sealed environment of the vacuum sealing machine requires a gearbox that functions reliably and with minimal maintenance, making Anaheim Automation planetary gearboxes an ideal choice for this application.

Beverage Multipack Machines

Beverage Multipack Machines - Beverage multipack systems are designed to enclose multiple beverage containers, such as bottles or cans, into a single package for easy handling, transport, and eventual retail sale. These systems typically use robotic arms and conveyors to quickly and efficiently package beverages, reducing the need for manual labor. Additionally, they can be customized to handle a variety of container types and sizes, making them a versatile solution for beverage manufacturers.

Products for Beverage Multipack Machines

VFDs

Variable frequency drives are often used in beverage multipack machines to control the speed of the motors which power the various stages of the packaging process. By adjusting the frequency of the electrical current supplied to the motors, VFDs allow for precise control over the speed and torque of the system, enabling them to operate at optimal efficiency while minimizing energy waste. This helps to ensure consistent product quality and throughput while reducing costs and increasing productivity.

Servo

Servo motors ensure precise and accurate movement control for the various components involved in the beverage packaging process. These motors can be used to control multiple components of the machine, including conveyor belts and X-Y stages. Servos help increase production speed and efficiency by allowing the system to perform multiple packaging functions simultaneously.

Linear Guides

Linear guides provide smooth linear motion in beverage packaging machines, especially in the labeling and sealing processes. The addition of linear guides allows the machine to achieve high accuracy and consistency, resulting in high-quality product uniformity and throughput. Additionally, linear guides are designed to withstand the harsh environment often found in beverage packaging applications, with materials that are resistant to corrosion, wear, and contamination.