We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

- Home

- Blog

- Blog Posts

- Linear Guides vs Linear Actuators: Understanding the Differences

Linear Guides vs Linear Actuators: Understanding the Differences

Linear Guides vs Linear Actuators: Understanding the Differences

In the world of motion control and automation, Linear Guides and Linear Actuators are essential components that serve distinct but sometimes complementary roles. Understanding their functions, mechanisms, and use cases is key to selecting the right component for your application.

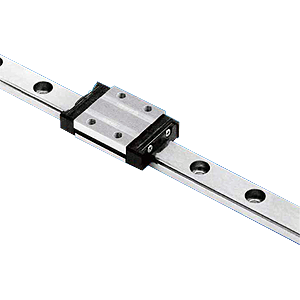

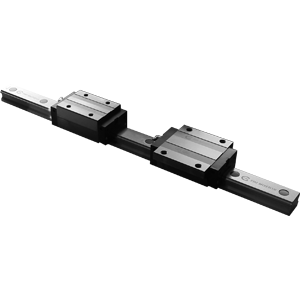

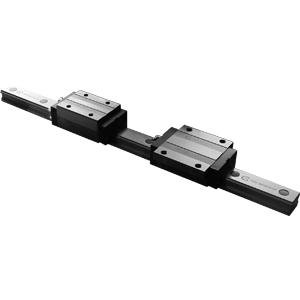

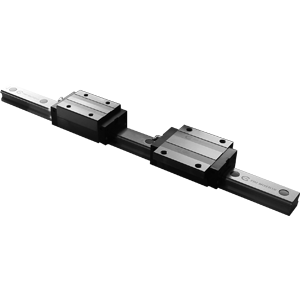

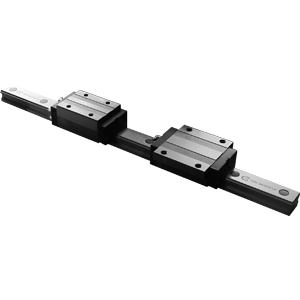

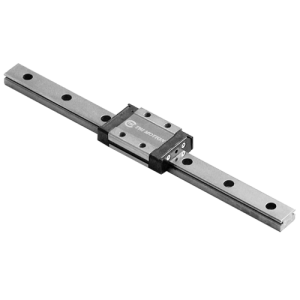

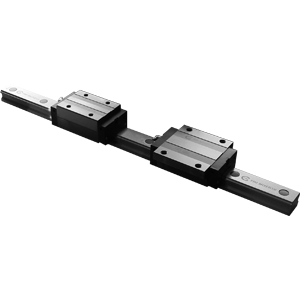

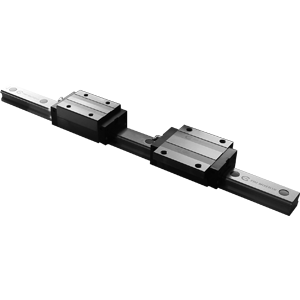

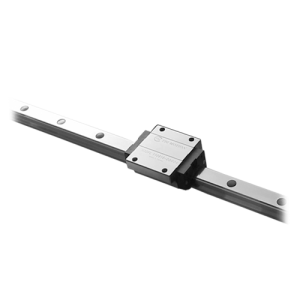

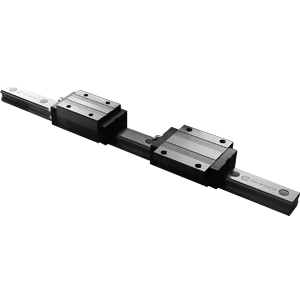

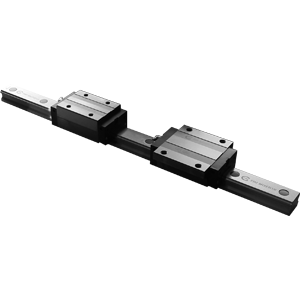

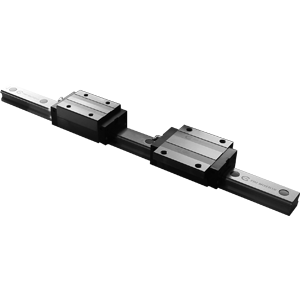

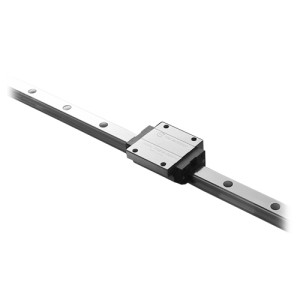

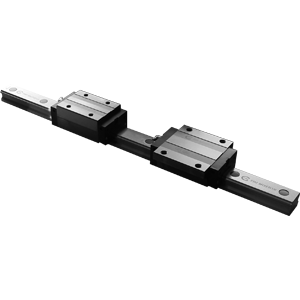

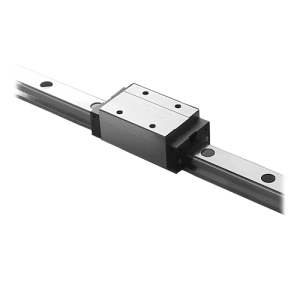

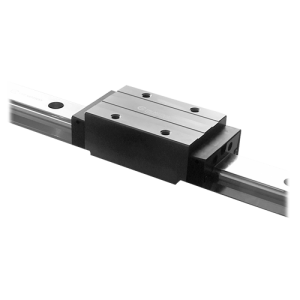

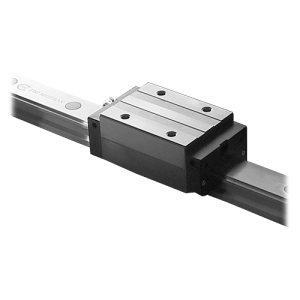

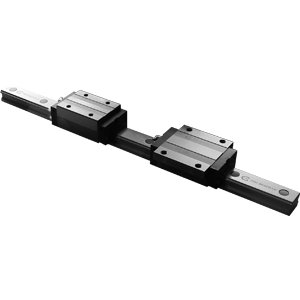

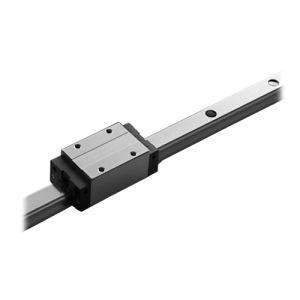

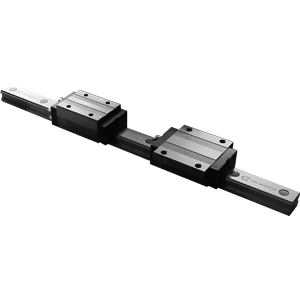

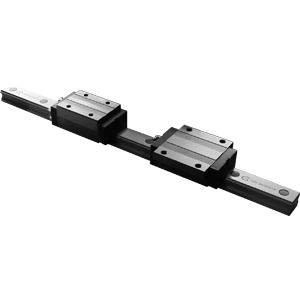

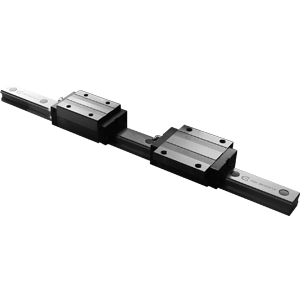

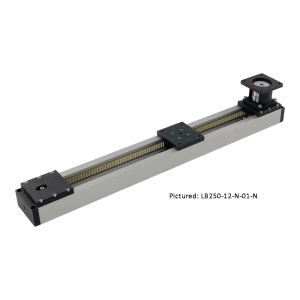

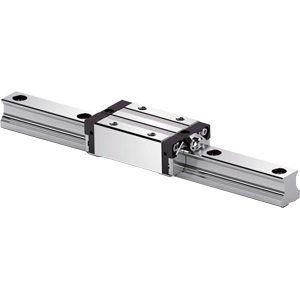

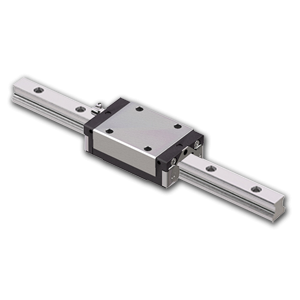

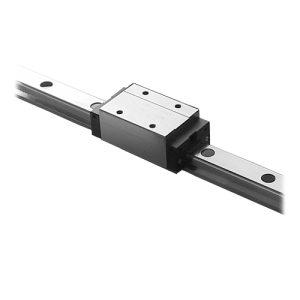

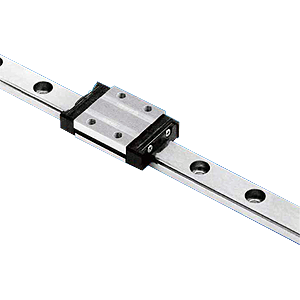

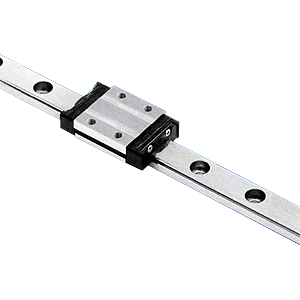

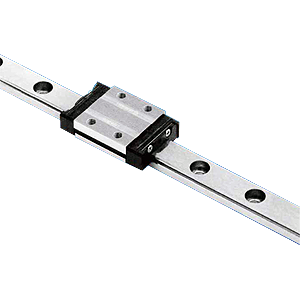

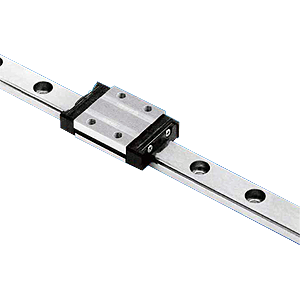

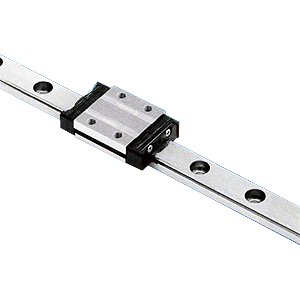

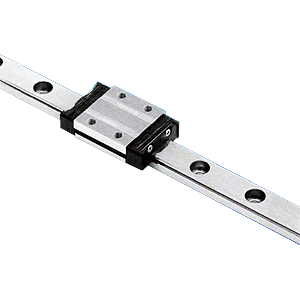

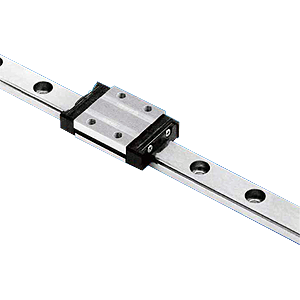

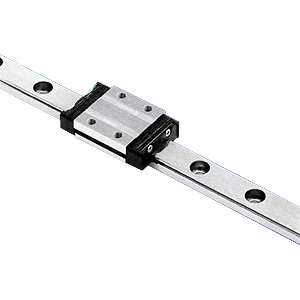

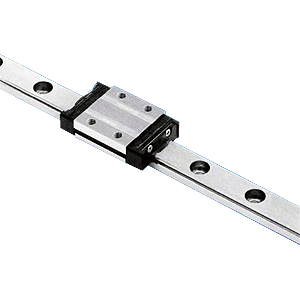

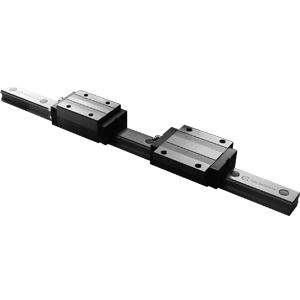

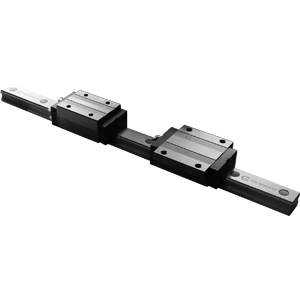

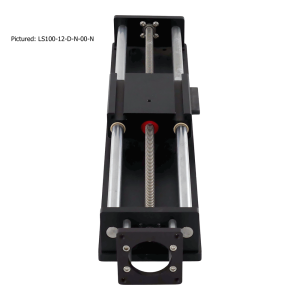

What are Linear Guides?

Linear guides (also known as linear rails or guideways) are mechanical components that provide smooth, precise linear motion along a defined path. They do not generate motion on their own; instead, they support and guide a moving load along a linear axis, typically with the help of ball bearings or rollers inside a rail system.

Key Characteristics:

- Passive component - requires external actuation

- High load capacity and rigidity

- Minimal friction and high accuracy

- Can support heavy or unevenly-distributed loads

- Commonly made from hardened steel or aluminum

Operation:

Linear guides consist of a rail and a carriage (or block). As an external actuator (such as a motor or screw drive) moves the carriage, the bearings allow smooth, low-resistance travel along the rail.

Typical Applications:

- CNC machines and milling equipment

- 3D printers and laser cutters

- Semiconductor inspection systems

- Automated pick-and-place arms

In these setups, linear guides provide stable, accurate movement, especially when carrying high loads or requiring precise repeatability.

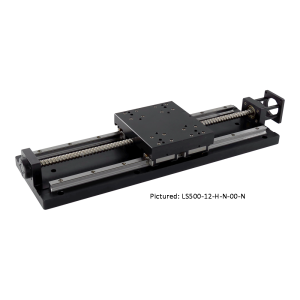

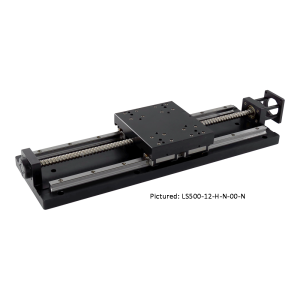

Popular Linear Guides:

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

-

-

-

-

-

-

-

-

-

-

-

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

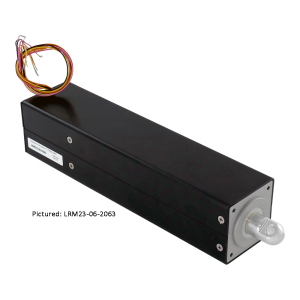

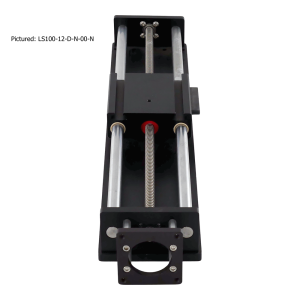

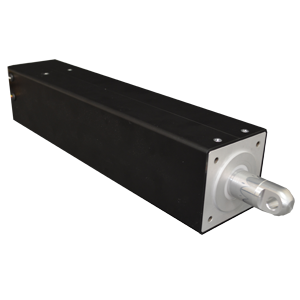

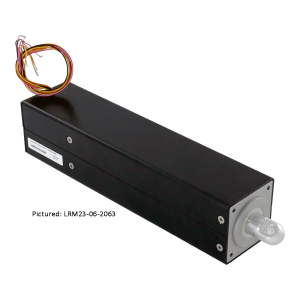

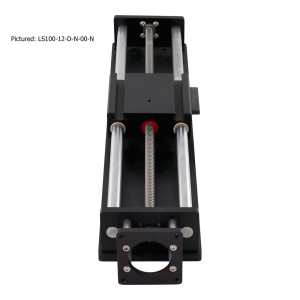

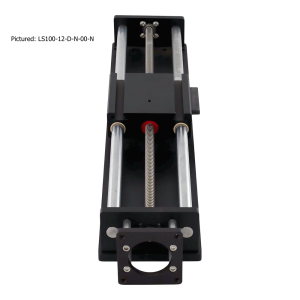

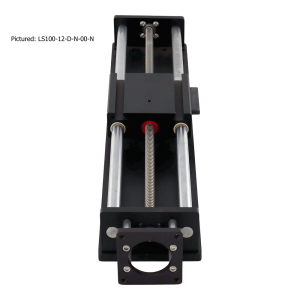

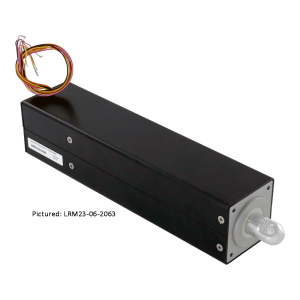

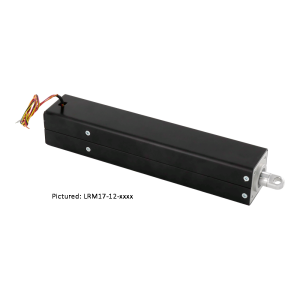

What are Linear Actuators?

Linear actuators are powered devices that create linear motion by converting rotary motion (from a motor) into straight-line movement. They include internal mechanisms such as lead screws, ball screws, belts, or linear motors that actively drive a load along a linear path.

Key Characteristics:

- Active motion - self-contained motion generation

- Includes a motor, drive mechanism, and often an encoder

- Can be electromechanical, pneumatic, or hydraulic

- Designed for controlled, programmable movement

- Available in compact to heavy-duty formats

Operation:

In an electric linear actuator, a motor drives a threaded shaft or belt that moves a nut or carriage along its axis. This enables precise, controllable linear movement without requiring additional actuation hardware.

Typcal Applications:

- Biomedical devices and automated lab equipment

- Packaging and labeling machines

- Robotic end-effectors

- Adjustable lift systems

Linear actuators are ideal where automated, programmable linear motion is required, especially in systems where standalone movement simplifies the overall design and wiring.

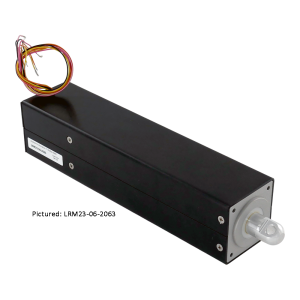

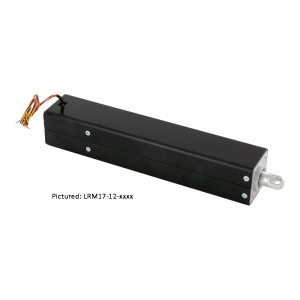

Popular Linear Actuators:

-

-

-

-

-

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

-

Add to CompareOut of stock

Add to CompareOut of stock -

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

-

-

-

-

-

-

-

-

-

-

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

-

-

-

Add to CompareOut of stock

Add to CompareOut of stock -

-

-

-

-

Add to CompareOut of stock

Add to CompareOut of stock -

-

-

-

Add to CompareOut of stock

Add to CompareOut of stock -

-

Add to CompareOut of stock

Add to CompareOut of stock -

-

-

-

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

-

-

Add to CompareOut of stock

Add to CompareOut of stock -

-

Add to CompareOut of stock

Add to CompareOut of stock -

-

Add to CompareOut of stock

Add to CompareOut of stock -

-

-

-

-

-

Add to CompareOut of stock

Add to CompareOut of stock -

-

-

Add to CompareOut of stock

Add to CompareOut of stock -

-

-

-

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

Add to CompareOut of stock

Add to CompareOut of stock -

-

Add to CompareOut of stock

Add to CompareOut of stock -

-

When to Use Each

| Scenario | Best Fit | Reason |

| Precise guidance of a heavy load | Linear Guide | High load capacity and smooth tracking |

| Integrated motion with minimal parts | Linear Actuator | Built-in drive eliminates external part requirements |

| CNC or machine tool motion systems | Linear Guide | Accuracy and repeatability under load |

| Light-duty motion in medical devices | Linear Actuator | Compact size, quiet operation, programmable |

| Multi-axis automated equipment | Both Combined | Actuator for motion, guide for support |

While both linear guides and linear actuators enable linear motion, their roles are fundamentally different. Linear guides provide support and direction, while linear actuators deliver powered motion. In many systems, these components work together—guides manage the load while actuators move it.

Choosing the right component depends on your application’s requirements for load capacity, precision, motion control, and system complexity.